Nitrogen halamine type antibacterial polyurethane material as well as preparation method and application thereof

A polyurethane material, nitrogen halamine type technology, used in polyurea/polyurethane coatings, textiles and papermaking, antifouling/underwater coatings, etc., can solve the problems of low efficiency, non-persistent and unstable nitrogen halamine type compounds, etc. , to achieve the effect of low cytotoxicity, low price and easy availability, and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a preparation method of nitrogen halide type antibacterial polyurethane material, comprising the following steps:

[0037] S1. Add 10 to 20 parts of guanidine salt, 1 to 5 parts of 2-acetylbutyrolactone, 4 to 11 parts of triethylamine and 15 to 29 parts of absolute ethanol in parts by weight and stir in the reactor for 30 to 60 minutes. React at 70-80°C for 24-48 hours, cool down to room temperature, and rinse with ethanol to obtain nitrogen haloamine precursor A, whose structural formula is:

[0038]

[0039] S2. Add 20 to 30 parts of polyol, 4 to 8 parts of diisocyanate, and 5 to 12 parts of N,N-dimethylformamide into another reactor, and then add 0.002 to 0.004 parts of catalyst. React at ~85°C for 2 to 4 hours to prepare prefabricated material B;

[0040] S3. Add 18-26 parts of N,N-dimethylformamide, 0.4-1.0 parts of chain extender and 0.1-0.6 parts of nitrogen halide to the preform B prepared in S2. The amine precursor A is ...

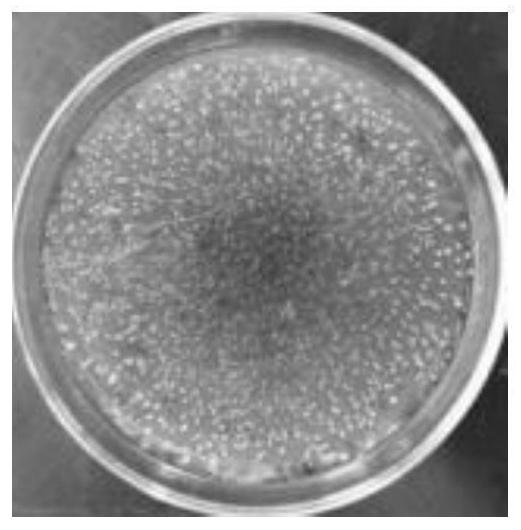

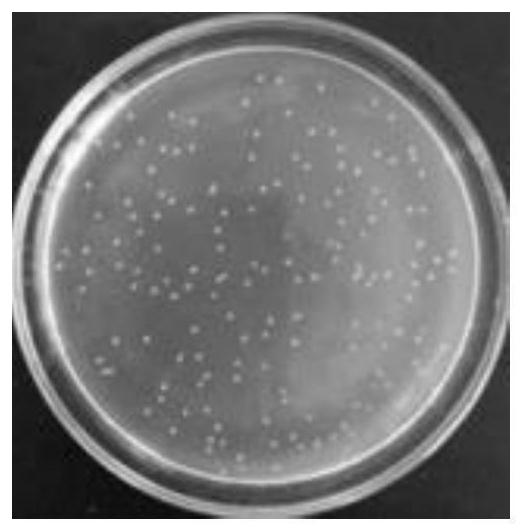

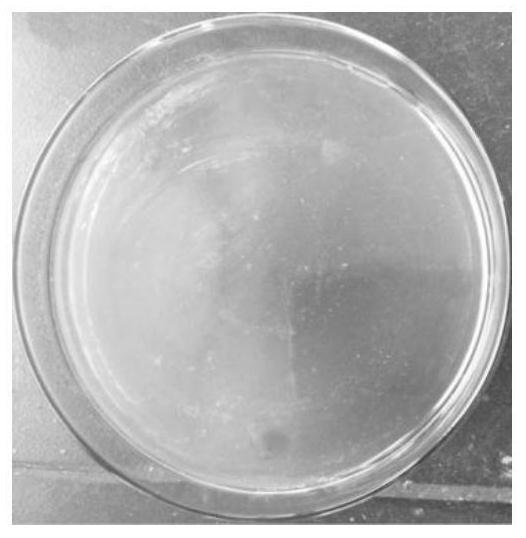

Embodiment 1

[0048] This embodiment provides a nitrogen halide type antibacterial polyurethane material that can be used in fields such as toy coatings, textile coatings, and medical devices, which is prepared by the following process:

[0049] S1. Add 10 parts of guanidinium carbonate, 2 parts of 2-acetylbutyrolactone, 4 parts of triethylamine, and 20 parts of absolute ethanol into the reactor in parts by weight and stir for 30 minutes, then react at 78°C for 24 hours, After cooling down to room temperature, after rinsing with ethanol, the nitrogen haloamine precursor A is obtained;

[0050]S2. Add 20 parts of polyether N220, 5 parts of aliphatic diisocyanate IPDI, and 7 parts of N,N-dimethylformamide DMF into another reactor, and add 0.002 parts of catalyst to it, and in a nitrogen atmosphere React at 80°C for 2 hours to prepare preform B;

[0051] S3. Add 20 parts of N,N-dimethylformamide DMF, 0.8 parts of chain extender BDO and 0.15 parts of nitrogen haloamine precursor dried under va...

Embodiment 2

[0055] This embodiment provides a nitrogen halide type antibacterial polyurethane material that can be used in fields such as toy coatings, textile coatings, and medical devices, which is prepared by the following process:

[0056] S1. Add 10 parts of guanidinium carbonate, 2 parts of 2-acetylbutyrolactone, 4 parts of triethylamine, and 20 parts of absolute ethanol into the reactor in parts by weight and stir for 30 minutes, then react at 78°C for 24 hours, After cooling down to room temperature, after rinsing with ethanol, the nitrogen haloamine precursor A is obtained;

[0057] S2. Add 20 parts of polyether N220, 5 parts of aliphatic diisocyanate IPDI, and 7 parts of N,N-dimethylformamide DMF into another reactor, and add 0.002 parts of catalyst to it, and in a nitrogen atmosphere React at 80°C for 2 hours to prepare preform B;

[0058] S3. Add 20 parts of N,N-dimethylformamide DMF, 0.8 part of chain extender BDO and 0.2 part of nitrogen haloamine precursor dried under vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com