Full-biodegradable foaming net and preparation method thereof

A foaming net and all-biological technology, applied in the field of foaming materials, can solve problems such as poor resilience, achieve good compatibility, increase strength, and suitable production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

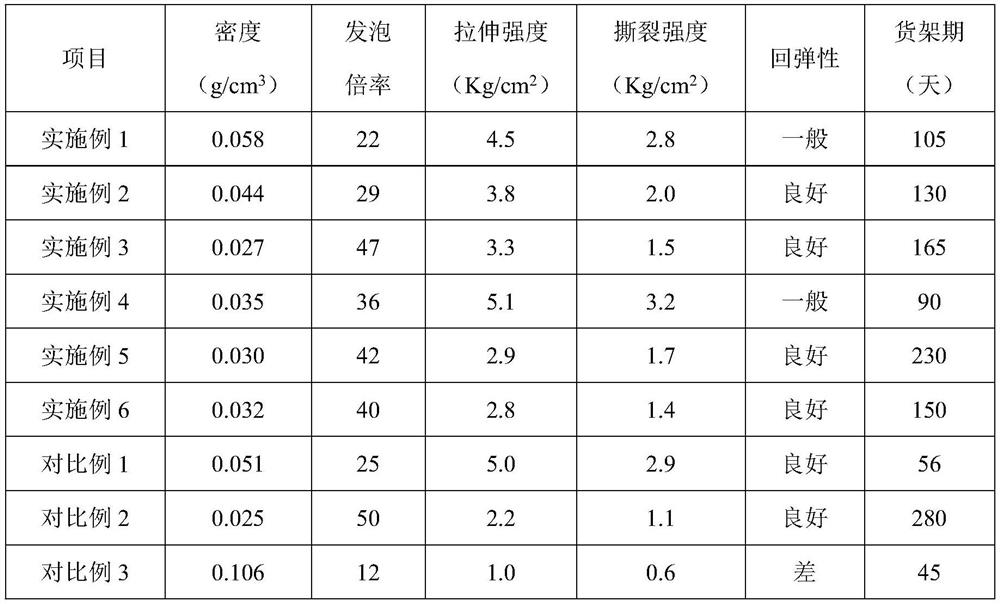

Examples

Embodiment 1

[0035] The foam net material consists of 60 parts of PBAT, 10 parts of PBS, 30 parts of PGA, 1 part of compatibilizer styrene-glycidyl methacrylate, 1 part of antihydrolysis agent polycarbodiimide, bis(2,4 - 0.4 parts of di-tert-butylphenyl) pentaerythritol diphosphite, 1 part of organic nucleating agent TMC-200, 1 part of TMC-306, 4 parts of inorganic nucleating agent talcum powder, 0.3 parts of lubricant ethylene bis stearamide 0.2 parts of anti-shrinkage agent monoglyceride, 1 part of antioxidant 1010, and 2 parts of white masterbatch.

[0036] The preparation process of the foam net is to mix PBAT, PBS, PGA, compatibilizer, anti-hydrolysis agent, nucleating agent, lubricant, anti-shrinkage agent, antioxidant, and color masterbatch evenly, and then mix it in a special double-layer for biodegradable plastics. The screw extruder is melted and mixed, and granulated to obtain a foamed modified base material. The temperature of zone 1-9 of the extruder is 160°C, 180°C, 200°C, 2...

Embodiment 2

[0039]The foam net material components are 60 parts of PBAT, 20 parts of PBS, 20 parts of PGA, 0.8 parts of compatibilizer ethylene-methyl acrylate-glycidyl methacrylate, 0.8 parts of anti-hydrolysis polycarbodiimide, cyclic 0.4 part of pentapentane tetrayl bis (2,6-di-tert-butyl-4-methylphenyl phosphite), 1 part of organic nucleating agent TMC-200, 1 part of TMC-300, inorganic nucleating agent carbonic acid Calcium 3 parts, lubricant erucamide 0.3 part, anti-shrinkage agent monoglyceride 0.2 part, antioxidant 1790 0.8 part, pink masterbatch 2 parts.

[0040] The preparation process of the foam net is to mix PBAT, PBS, PGA, compatibilizer, anti-hydrolysis agent, nucleating agent, lubricant, anti-shrinkage agent, antioxidant, and color masterbatch evenly, and then mix it in a special double-layer for biodegradable plastics. The screw extruder is melted and mixed, and granulated to obtain a foamed modified base material. The temperature of zone 1-9 of the extruder is 160°C, 180...

Embodiment 3

[0043] The foam net material components are 60 parts of PBAT, 30 parts of PBS, 10 parts of PGA, 0.6 parts of compatibilizer styrene-acrylonitrile-glycidyl methacrylate, 0.6 parts of anti-hydrolysis polycarbodiimide, bis( 0.2 parts of 2,4-di-tert-butylphenyl) pentaerythritol diphosphite, 1.5 parts of organic nucleating agent TMC-306, 2 parts of inorganic nucleating agent silicon dioxide, 0.3 parts of lubricant stearic acid, anti-shrinkage agent 0.2 part of monoglyceride, 0.6 part of antioxidant 1024, 2 parts of yellow masterbatch.

[0044] The preparation process of the foam net is to mix PBAT, PBS, PGA, compatibilizer, anti-hydrolysis agent, nucleating agent, lubricant, anti-shrinkage agent, antioxidant, and color masterbatch evenly, and then mix it in a special double-layer for biodegradable plastics. The screw extruder is melted and mixed, and granulated to obtain a foamed modified base material. The temperature of zone 1-9 of the extruder is 160°C, 180°C, 200°C, 210°C, 220...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com