Fuel oil steam isolation coating for carrying traffic oil tank and preparation method of same

A technology for isolating coatings and fuel vapor, applied in the field of materials, can solve problems such as fuel vapor leakage and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

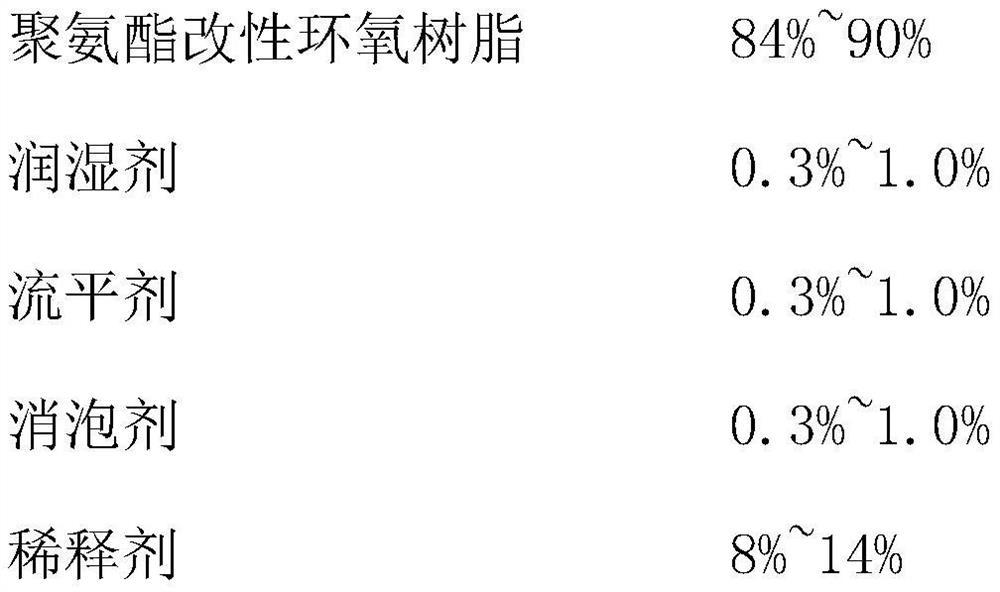

[0047] (1) Preparation of component A of the fuel vapor isolation coating for transportation fuel tanks: Add 0.5kg of wetting agent BYK-330 and 0.5kg of leveling agent BYK- 320. 0.4 kg of defoamer BYK-066N and 11.6 kg of diluent (xylene: cyclohexanone: butanone = 2:1:1) were stirred at high speed to disperse evenly, and the material was filtered to obtain component A.

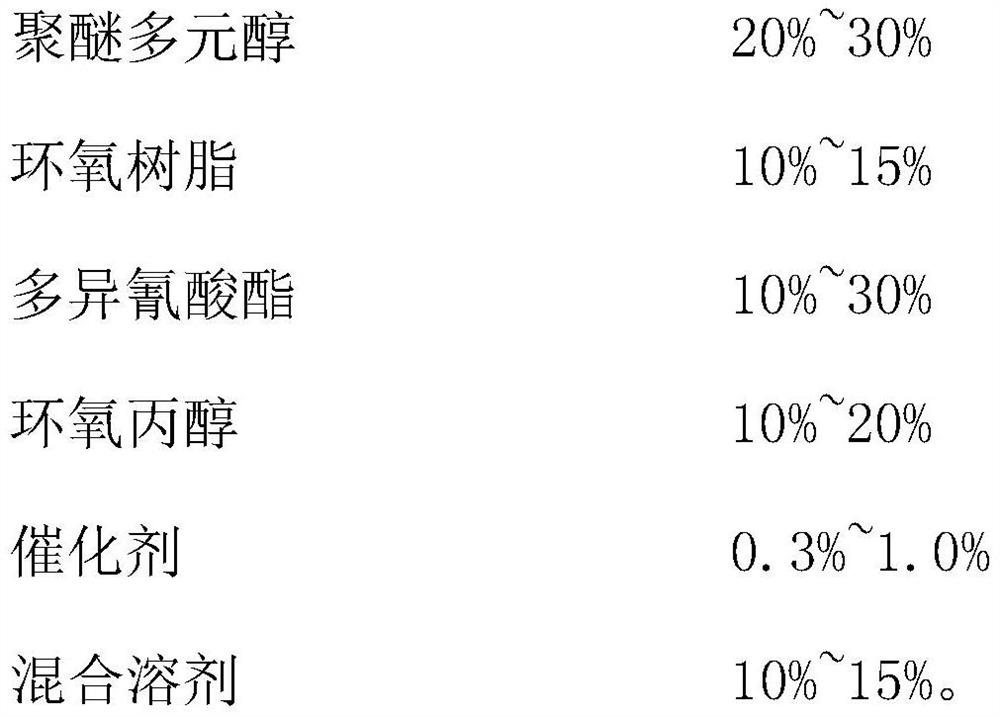

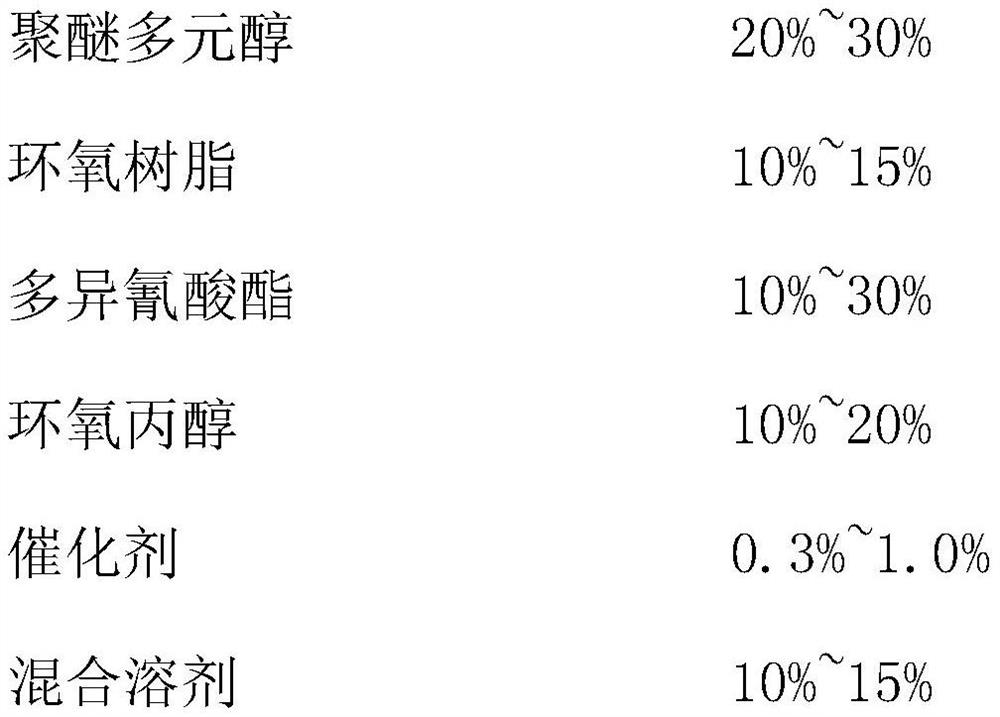

[0048] Wherein the preparation method of self-made polyurethane modified epoxy resin is: take 18kg difunctional polyether polyol D210 and 12kg trifunctional polyether polyol G303 and add in the reaction kettle for dehydration treatment, add 14.6kg epoxy resin E-44 to increase Polymer crosslinking point, fully stirred evenly, put 24.6kg polyisocyanate IPDI into the reactor, add 0.7kg catalyst dibutyltin dilaurate, react at 60-80°C for 5 hours, and obtain isocyanate group-terminated polyurethane prepolymer. After the temperature drops to normal temperature, put 17.7kg of glycidyl alcohol into the reaction kettle,...

Embodiment 2

[0051] (1) Preparation of component A of the fuel vapor isolation coating for transportation fuel tanks: Add 0.6 kg of wetting agent BYK-310 and 0.6 kg of leveling agent BYK- 358N, 0.5kg of defoamer BYK-A530 and 8.3kg of diluent (xylene:cyclohexanone:butanone=2:1:1) were stirred at high speed to disperse evenly, and the material was filtered to obtain component A.

[0052] Wherein the preparation method of self-made polyurethane modified epoxy resin is: take 15kg difunctional polyether polyol D210 and 15kg trifunctional polyether polyol G303 and add in the reaction kettle for dehydration treatment, add 13.8kg epoxy resin E-44 to increase Polymer crosslinking point, fully stirred evenly, put 25.2kg polyisocyanate IPDI into the reactor, add 0.7kg catalyst dibutyltin dilaurate, react at 60-80°C for 5 hours, and obtain isocyanate group-terminated polyurethane prepolymer. After the temperature drops to normal temperature, put 16.7kg of glycidyl alcohol into the reaction kettle, add...

Embodiment 3

[0055] (1) Preparation of component A of the fuel vapor isolation coating for transportation fuel tanks: Add 0.7kg of wetting agent BYK-330 and 0.7kg of leveling agent BYK- 358N, 0.4kg of defoamer BYK-066N and 8.2kg of diluent (xylene: cyclohexanone: butanone = 2:1:1) were stirred at high speed to disperse evenly, and the material was filtered to obtain component A.

[0056] The preparation method of self-made polyurethane modified epoxy resin is as follows: take 24kg of difunctional polyether polyol D204 and 6kg of trifunctional polyether polyol G4030 and add them to the reaction kettle for dehydration treatment, and add 15kg of epoxy resin E-44 to increase the polymerization rate. Stir well to obtain the crosslinking point of the compound, put 23.4kg of polyisocyanate IPDI into the reactor, add 0.9kg of catalyst dibutyltin dilaurate, and react at 60-80°C for 5 hours to obtain isocyanate group-terminated polyurethane prepolymer. After the temperature drops to normal temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com