Method for enzymatic synthesis of fumaric acid trehalose ester in non-aqueous phase medium

A technology of non-aqueous phase medium and trehalose ester, which is applied in the direction of chemical instruments and methods, esterified saccharides, sugar derivatives, etc., can solve the problem of unexperimented, unmentioned trehalose fumarate, and unseen problems. Fumarate trehalose esterase catalytic research and production reports and other issues, to achieve the effect of single product and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

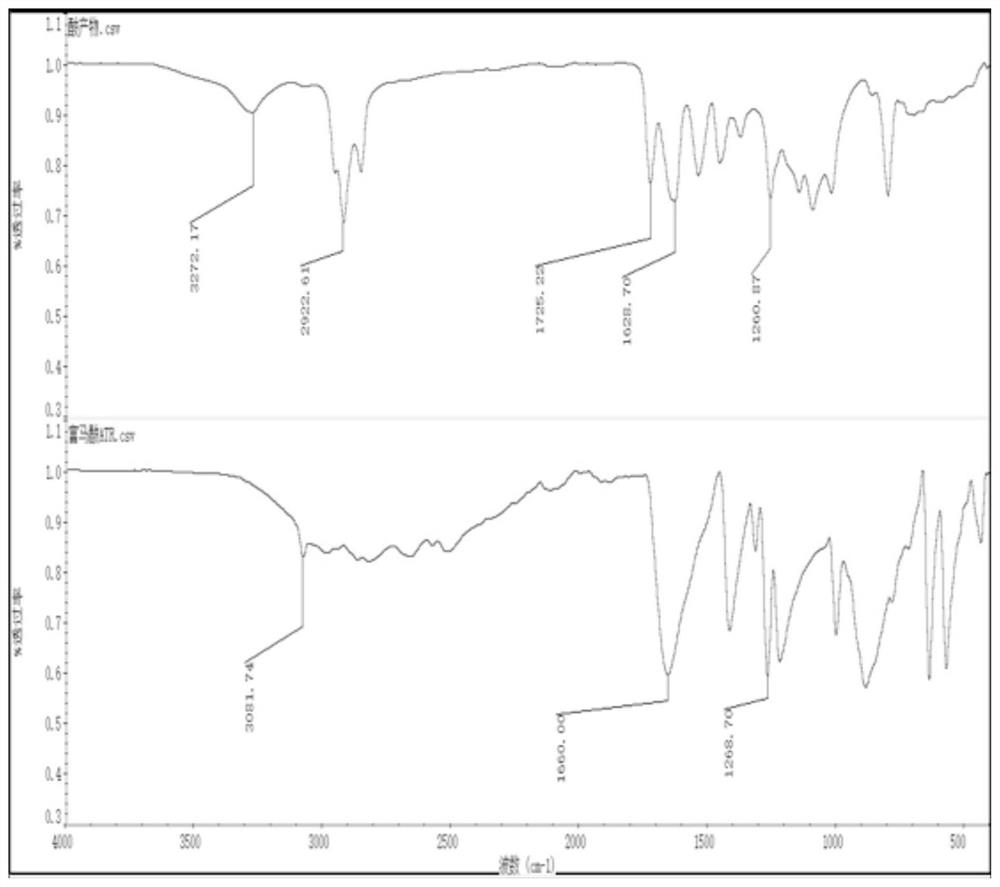

Image

Examples

Embodiment 1

[0035] Example 1: Non-aqueous phase enzyme-catalyzed synthesis of alginate fumarate

[0036] 1. Use a muffle furnace at 500°C for 5 hours to activate the molecular sieve, add the molecular sieve to acetone, let it stand for 24 hours to remove water, and then add reagents to react according to the following steps:

[0037] (1) Trehalose is difficult to dissolve in acetone, so the amount of trehalose added is 10mmol / L;

[0038] (2) The constant temperature conditions are determined. In the experiment, 25°C, 30°C, 35°C, 40°C, 45°C, and 50°C were selected as the reaction temperature. At 50°C, acetone will completely volatilize in the constant temperature incubator, which is not conducive to the reaction. , the yield was the highest at 30°C, so 30°C was selected as the optimal condition;

[0039] (3) Oscillation conditions were determined. In the experiment, 100rpm, 125rpm, 150rpm, 175rpm, and 200rpm were selected as the oscillation conditions, and 150rpm was selected for the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com