Polymer-based semiconductor fiber and preparation and application thereof

A semiconductor and polymer technology, which is applied in the continuous production process of polymer-based highly oriented semiconductor fibers and related application fields, can solve problems such as poor mechanical properties, complex preparation methods, and multi-transistor circuit integration, and achieves good uniformity, Good toughness and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

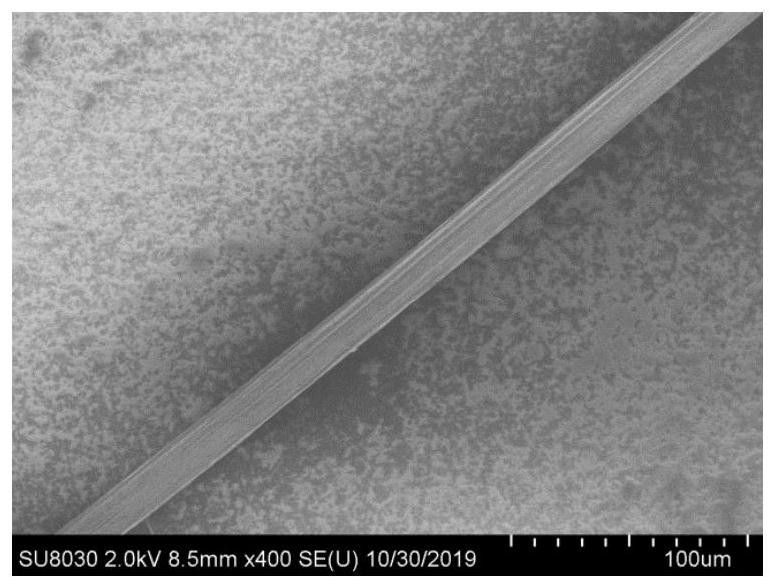

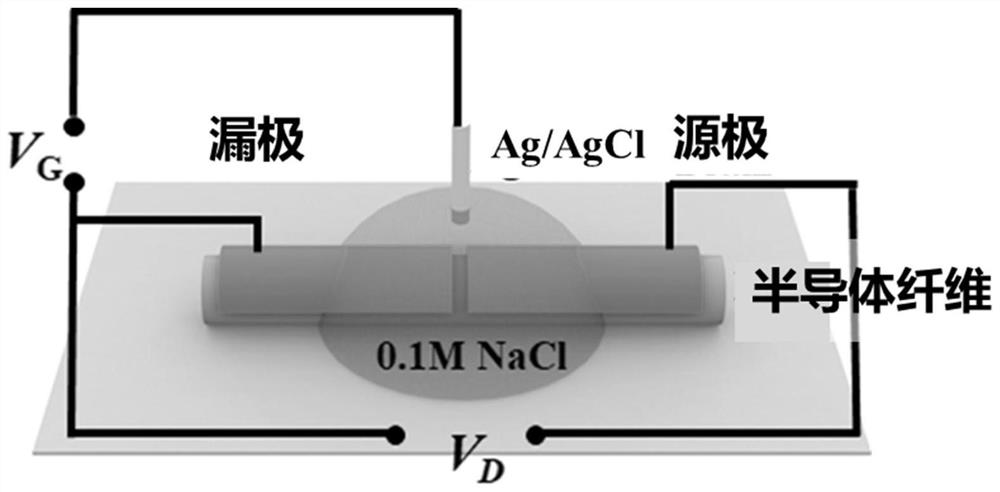

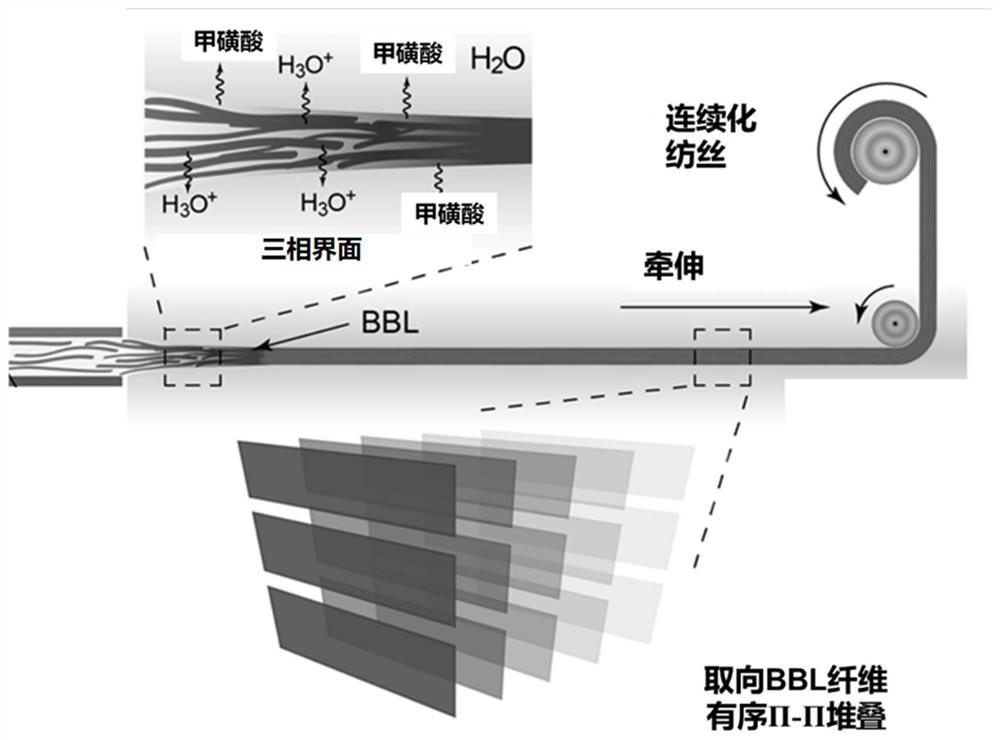

[0076] A method for preparing a polymer-based semiconductor fiber, comprising the steps of:

[0077] (1) configuring the conjugated semiconducting polymer as a spinning stock solution for wet spinning;

[0078] The conjugated semiconducting polymer is: BBL.

[0079] The solvent of spinning dope is: methanesulfonic acid;

[0080] In the spinning dope, the concentration of the conjugated semiconducting polymer is 5 mg ml -1 .

[0081] (2) The spinning dope obtained in step (1) is subjected to wet spinning, and the fine spinning stream extruded from the spinneret enters the first coagulation bath and the second coagulation bath successively and then is dried, and then the dried The fibers are collected, and the drawing is continued during the process from the extrusion of the spinneret to the collection, and the draft ratio is 2; then the collected fibers are annealed to obtain polymer-based semiconductor fibers;

[0082] The spinneret is #1 spinneret, and the extrusion speed...

Embodiment 2

[0089] A method for preparing a polymer-based semiconductor fiber, comprising the steps of:

[0090] (1) configuring the conjugated semiconducting polymer as a spinning stock solution for wet spinning;

[0091] The conjugated semiconducting polymer is: P3CPT.

[0092] The solvent of spinning dope is: methanesulfonic acid;

[0093] In the spinning dope, the concentration of the conjugated semiconducting polymer is 5 mg ml -1 .

[0094] (2) The spinning dope obtained in step (1) is subjected to wet spinning, and the fine spinning stream extruded from the spinneret enters the first coagulation bath and the second coagulation bath successively and then is dried, and then the dried The fibers are collected, and the drawing is continued during the extrusion process from the spinneret to the collection, and the draft ratio is 1.5; then the collected fibers are annealed to obtain polymer-based semiconductor fibers;

[0095] The spinneret is #2 spinneret, and the extrusion speed of...

Embodiment 3

[0102] A method for preparing a polymer-based semiconductor fiber, comprising the steps of:

[0103] (1) configuring the conjugated semiconducting polymer as a spinning stock solution for wet spinning;

[0104] The conjugated semiconducting polymer is: polypyrrole.

[0105] The solvent of the spinning dope is: N,N-dimethylformamide;

[0106] In the spinning dope, the concentration of the conjugated semiconducting polymer is 5 mg ml -1 .

[0107] (2) The spinning stock solution obtained in step (1) is subjected to wet spinning, and the fine spinning stream extruded through the spinneret first enters the first coagulation bath and the second coagulation bath successively and then is dried, and then the dried The fibers are collected, and the drawing is continued during the extrusion process from the spinneret to the collection, and the draft ratio is 3; then the collected fibers are annealed to obtain polymer-based semiconducting fibers;

[0108] The spinneret is #3 spinnere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com