Aluminum alloy heat dissipation cavity structure containing heat accumulator for LED lamp and preparation method of aluminum alloy heat dissipation cavity structure

A technology of LED lights and aluminum alloys, applied in metal processing equipment, lighting and heating equipment, manufacturing tools, etc., can solve the problems of low phase transition temperature, inability to dissipate heat in time, and poor latent heat storage capacity, etc., to reduce thermal resistance , good heat conduction and heat storage phase change performance, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

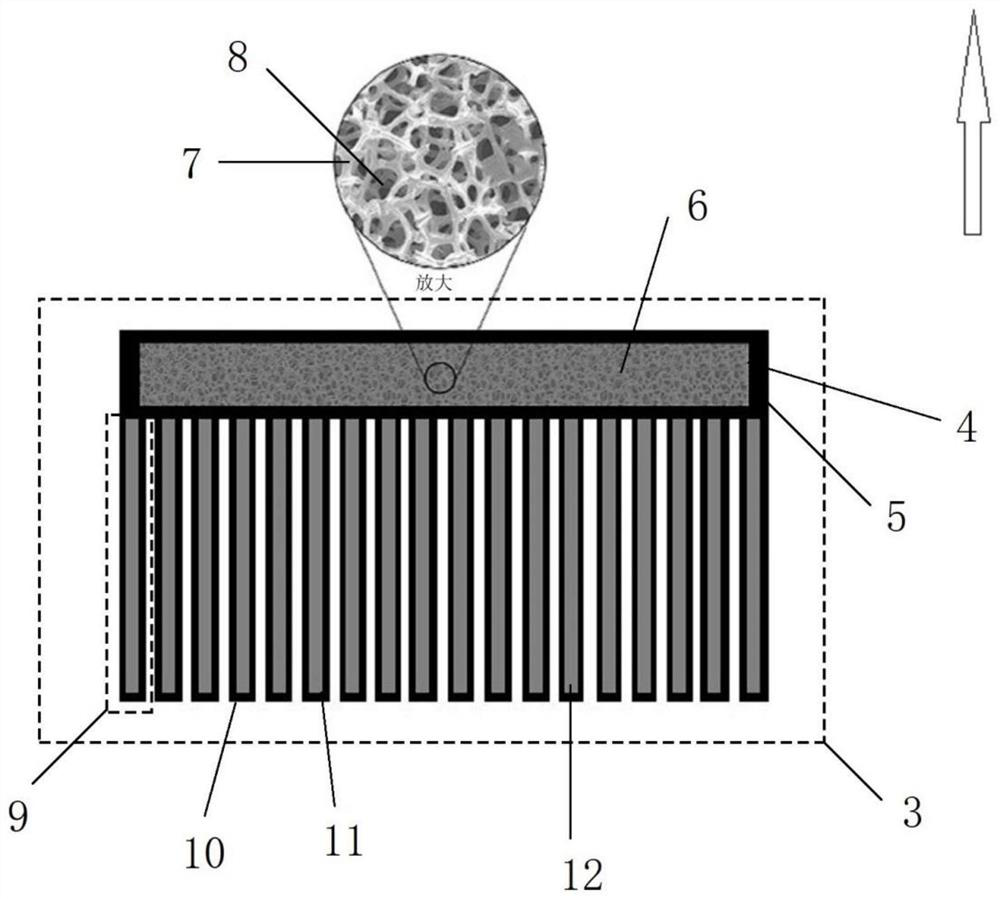

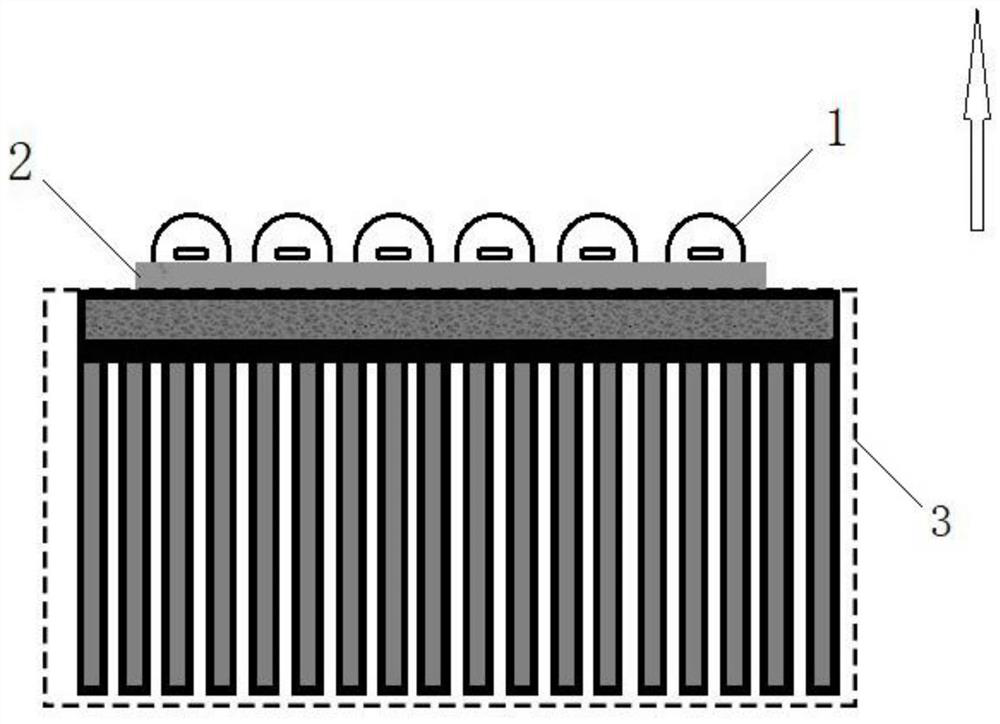

[0060] The invention also discloses a method for preparing an aluminum alloy heat dissipation cavity structure containing a heat storage body for an LED lamp, including an aluminum alloy heat dissipation cavity containing a heat storage body for an LED lamp as described in any one of claims 1 to 7 structure, the steps are as follows:

[0061] 1) Using the sand casting process to design the casting mold;

[0062] 2) Inject the aluminum alloy high-temperature melt into the casting mold;

[0063] 3) Take out half of the cast aluminum alloy cooling cavity structure 3;

[0064] 4) Premixing the phenolic resin and expanded graphite with a mass count ratio of 1:1, wherein the phenolic resin is a thermoplastic phenolic resin, and the expanded graphite particle size is greater than 0.045mm and less than 5mm;

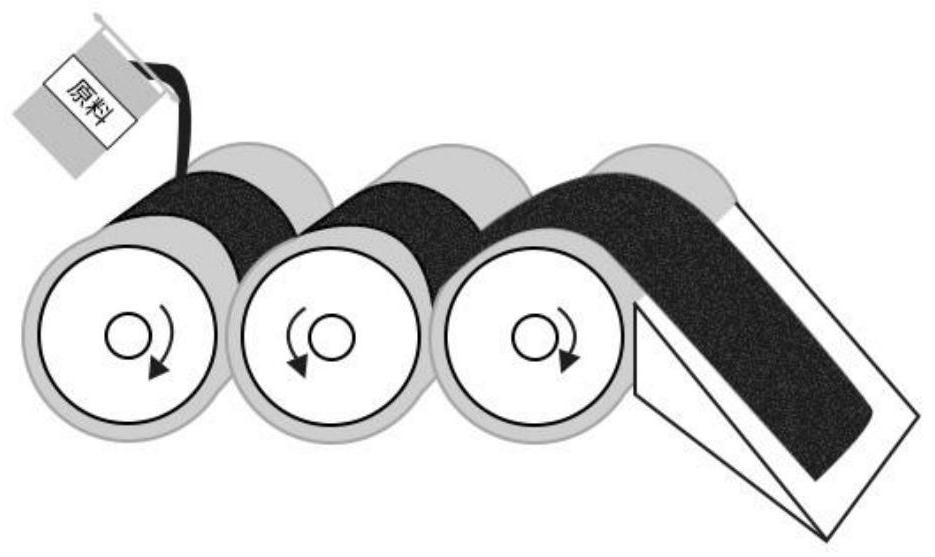

[0065] 5) Add the mixture to the three-roll mill for stripping and mixing, and circulate stripping and mixing for 10-16 times to obtain a graphene sheet / phenolic resin mixture;...

Embodiment 1

[0081] The preparation method of the aluminum alloy heat dissipation cavity structure containing the heat storage body for the LED lamp:

[0082] 1) Using the sand casting process to design the casting mold;

[0083] 2) Inject the aluminum alloy high-temperature melt into the casting mold;

[0084] 3) Take out half of the casted aluminum alloy cooling cavity 3 structure;

[0085] 4) Premixing the phenolic resin and expanded graphite with a mass count ratio of 1:1, wherein the phenolic resin is a thermoplastic phenolic resin, and the expanded graphite particle size is greater than 0.045mm and less than 5mm;

[0086] 5) Add the mixture to the three-roll mill for stripping and mixing, and circulate stripping and mixing for 10-16 times to obtain a graphene sheet / phenolic resin mixture;

[0087] 6) then powdery 10wt% EVA hot-melt wax, 20wt% hard wax, 40wt% microcrystalline wax, 10wt% polyethylene glycol are put into the three-roll grinder, mixed with 20wt% graphene sheet / phenolic...

Embodiment 2

[0095] The preparation method of the aluminum alloy heat dissipation cavity structure containing the heat storage body for the LED lamp:

[0096] 1) Using the sand casting process to design the casting mold;

[0097] 2) Inject the aluminum alloy high-temperature melt into the casting mold;

[0098] 3) Take out half of the cast aluminum alloy cooling cavity structure 3;

[0099] 4) Premixing the phenolic resin and expanded graphite with a mass count ratio of 1:1, wherein the phenolic resin is a thermoplastic phenolic resin, and the expanded graphite particle size is greater than 0.045mm and less than 5mm;

[0100] 5) Add the mixture to the three-roll mill for stripping and mixing, and circulate stripping and mixing for 10-16 times to obtain a graphene sheet / phenolic resin mixture;

[0101] 6) Put powdered 8wt% EVA hot melt wax, 15wt% hard wax, 45wt% microcrystalline wax, 10wt% polyethylene glycol into the three-roll mill, mix with 22wt% graphene sheet / phenolic resin mixture ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com