Substrate for silicon-based MOSFET device and production method thereof

A substrate and device technology, which is applied in the substrate of silicon-based MOSFET devices and its preparation, can solve the problems of low withstand voltage of MOSFET devices, improve performance and stability, and solve the effects of low withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

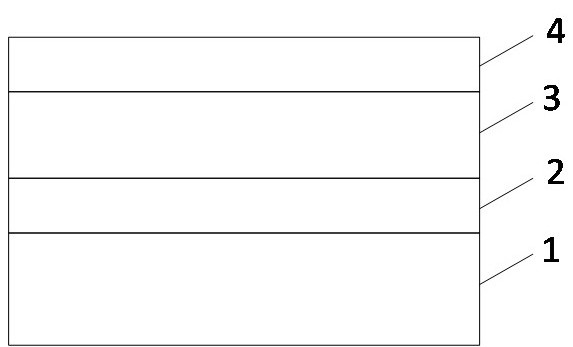

[0039] Specifically, the preparation method for the substrate of the silicon-based MOSFET device in the present application includes the following steps:

[0040] (1) Clean and dry the Si substrate.

[0041] In this step, the Si substrate may be cleaned and dried using an RCA standard cleaning process. The RCA standard cleaning process is a prior art and will not be repeated here. After cleaning and drying, put the Si substrate into chemical vapor deposition equipment.

[0042] (2) Etching the Si substrate.

[0043] In this step, the Si substrate is first etched, and the surface of the RCA-cleaned Si substrate will have an extremely thin layer of silicon oxide. Etching can remove the silicon oxide layer on the surface, which is beneficial to the subsequent film growth.

[0044] Specifically, step (2) includes the following steps:

[0045] Heat the Si substrate to 1000-1200°C, and pass in a flow rate of 3-5 slm of hydrogen (H 2 ) and hydrogen chloride (HCl) with a flow rate...

Embodiment 1

[0072] (1) RCA standard cleaning process is used to clean and dry the Si substrate with a thickness of 300 μm, and put the Si substrate into a high-temperature epitaxy furnace.

[0073] (2) Heating the Si substrate to 1200°C, passing H at a flow rate of 4 slm 2 and the mixed gas of HCl with a flow rate of 0.2 slm to etch the Si substrate for 10 min, and then turn off the gas source.

[0074] (3) Lower the temperature of the Si substrate to room temperature, and pass H at a flow rate of 4 slm 2 and C with a flow rate of 0.04slm 2 h 4 The mixed gas, the temperature of the Si substrate was raised to 1300°C within 1min, and kept for 1min, and a polycrystalline 3C-SiC buffer layer with a thickness of 15nm was grown on the surface of the Si substrate, and then the gas source was turned off.

[0075] (4) Raise the temperature of the Si substrate to 1350°C, and feed H at a flow rate of 4 slm 2 , SiH at a flow rate of 0.08 slm 4 and C with a flow rate of 0.04slm 2 h 4 A mixed ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com