Preparation method of alkyl lithium sulfate

A technology of lithium alkyl sulfate and silicon alkyl sulfate is applied in the field of preparation of lithium ion battery electrolyte additive lithium alkyl sulfate, which can solve the problem that the transesterification efficiency is difficult to reach 100%, the reaction of lithium chlorosulfonate is incomplete, and the Lithium chlorosulfonate is difficult to purify and other problems, to achieve the effect of loose reaction conditions, difficult to remove and easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method for alkyl lithium sulfate, comprising the following steps:

[0036] 1) Add 116.5 g (1 mol) of chlorosulfonic acid and 400 ml of dichloromethane to the flask under 0°C ice-water bath and nitrogen protection, and gradually add 102 g (1 mol) of triethylamine to the chlorosulfonic acid and trimethylchlorosilane 108.6 g (1 mol) mixed solution, after the dropwise addition, the temperature was raised to normal temperature, and the reaction was continued for 12 h until no precipitation occurred; after the reaction was completed, filtered to remove the insoluble triethylamine hydrochloride , After removing dichloromethane by rotary evaporation, re-filter, and then carry out rectification operation on the filtrate, collect the fraction at 60~70°C to obtain silicon chlorosulfonate.

[0037] 2) Put 94 g (0.5 mol) of silicon chlorosulfonate into a flask, and add 200 ml of dichloromethane after dehydration in an ice-water bath at 0°C under the protection of nitro...

Embodiment 2

[0041] A kind of preparation method of alkyl lithium sulfate, on the basis of embodiment 1, step 1) adopts following method:

[0042]1) Add 142 g (1.05 mol) of sulfonyl chloride into the flask under the protection of nitrogen in an ice-water bath at 0°C, and add zinc chloride with a molar fraction of 3%, then gradually add hexamethyl dichloride dropwise to the sulfonyl chloride Siloxane 162 g (1 mol), after the dropwise addition, raise the temperature to normal temperature, and continue to react for 12 h; after the reaction, filter, and then carry out rectification operation on the filtrate, remove the previous fraction (below 50°C), and collect Distillate at 60~70°C to obtain silicon chlorosulfonate.

[0043] Step 2) and step 3) are the same as in Example 1.

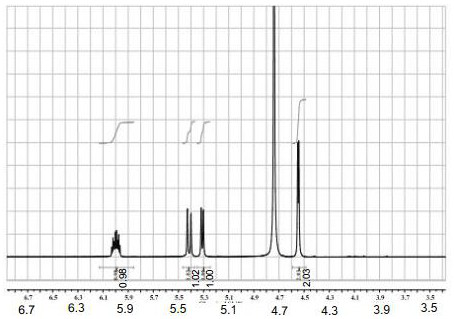

[0044] It was characterized by proton nuclear magnetic spectrum and ion chromatography, and the analysis and calculation showed that the yield of the product was 78.5%, and the purity was greater than 99.5% (characteri...

Embodiment 3

[0046] A preparation method of alkyl lithium sulfate, on the basis of Example 1, step 2) propylene alcohol is replaced by butenyl alcohol, the obtained in step 2) is silicon butenyl sulfate, and the final product obtained in step 3) is butane Lithium Alkenyl Sulfate.

[0047] Characterized by proton nuclear magnetic spectrum and ion chromatography, analysis and calculation can be obtained, the product yield is 79.6%, and the purity is greater than 99.5% (NMR characterization).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com