Preparation method of supramolecular hydrogel capable of being stretched in ultra-long mode

A supramolecular hydrogel and hydrogel technology, applied in the field of functional polymer materials, can solve the problems of gel network rupture and poor mechanical properties, and achieve the effects of excellent electrical conductivity, excellent adhesion, and excellent self-healing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

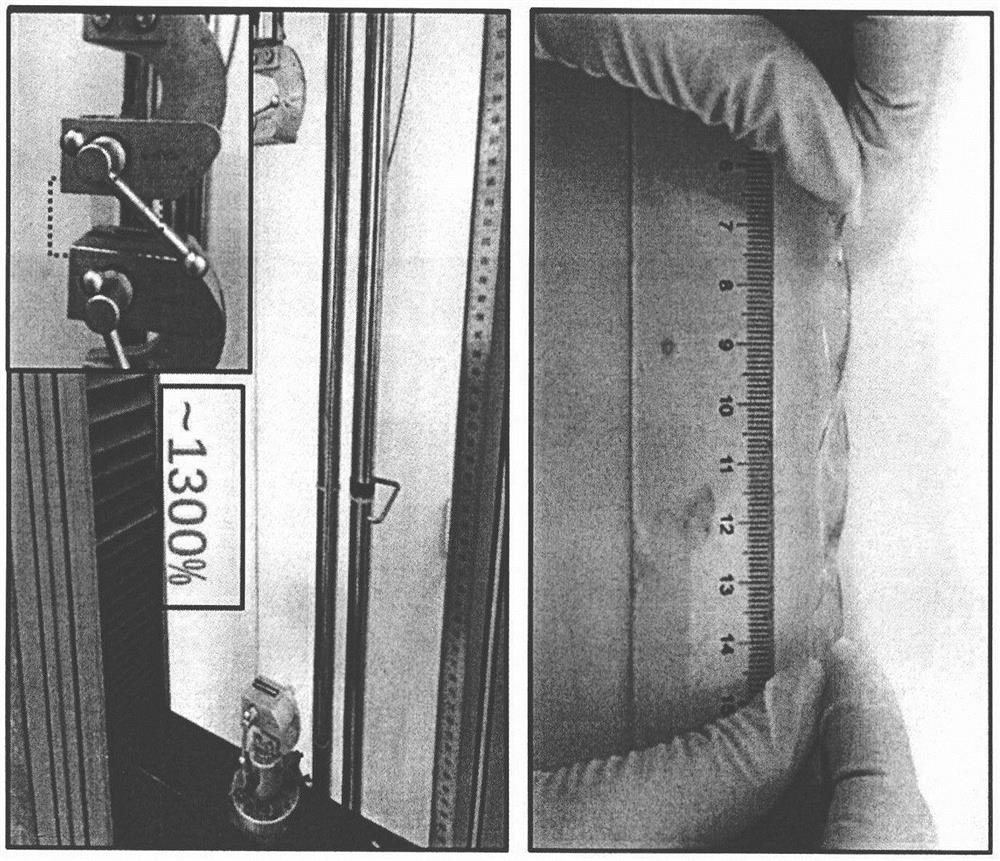

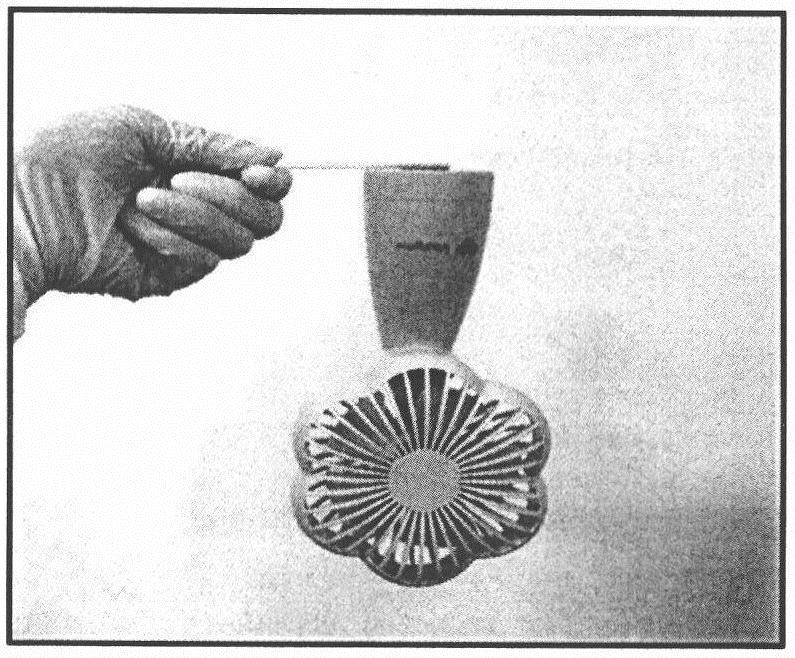

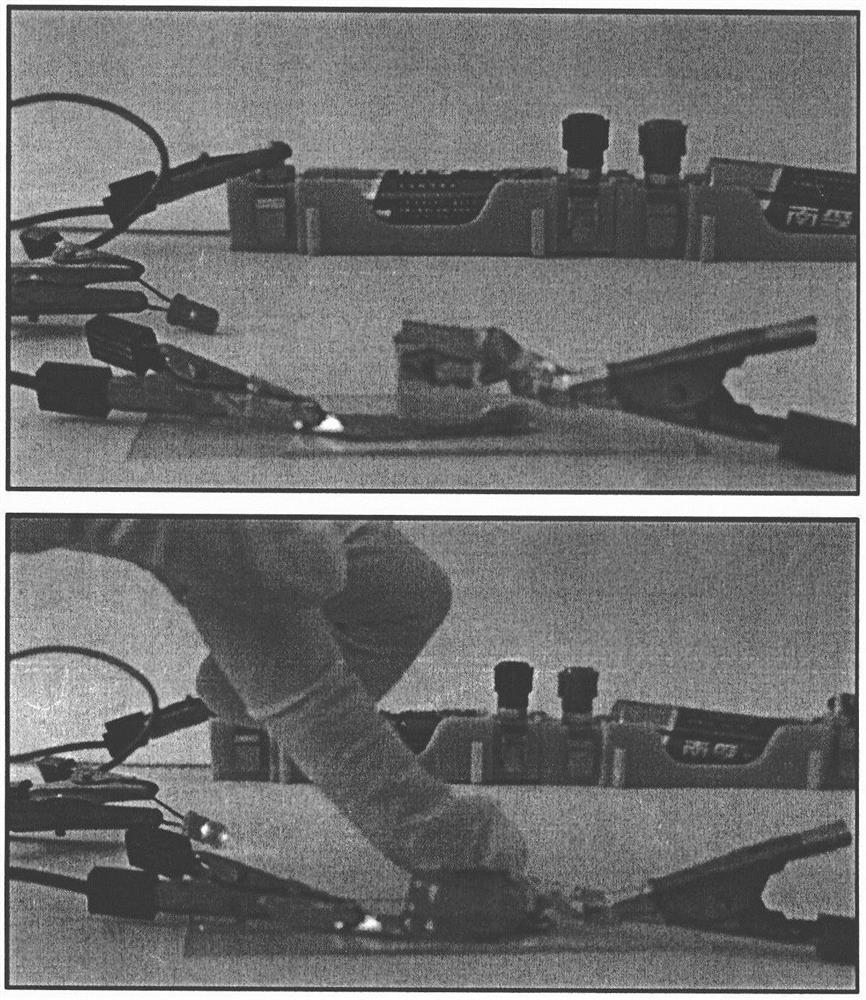

Image

Examples

Embodiment 1

[0033] 1) After 10 grams of polyethylene glycol was weighed and melted completely at 50°C, 0.08 grams of catalyst boron trifluoride ether was added, and 2.775 milliliters of epichlorohydrin was added dropwise at a speed of 0.5 mL / min, and the reaction was carried out for 4 hours. After completion of the reaction, excess epichlorohydrin was removed by distillation to obtain epoxy-modified polyethylene glycol.

[0034] 2) Disperse the lignosulfonate in 0.1M sodium hydroxide solution to prepare a dispersion liquid with a mass fraction of 25%, mix with the epoxy-modified polyethylene glycol obtained in the previous step, and continue to react for 4 hours. After the reaction is completed, it is cooled to room temperature, the pH value of the solution is adjusted to neutrality with dilute hydrochloric acid, and unreacted impurities are removed by continuous extraction with butanone, and the product is dried to obtain the product lignin-grafted polyethylene glycol.

[0035] 3) Disper...

Embodiment 2

[0038] 1) After 20 grams of polyethylene glycol was weighed and melted completely at 70°C, 0.2 grams of catalyst boron trifluoride ether was added, and then 3.255 milliliters of epichlorohydrin was added dropwise at a speed of 1 mL / min, and the reaction was carried out for 6 hours. After completion of the reaction, excess epichlorohydrin was removed by distillation to obtain epoxy-modified polyethylene glycol.

[0039] 2) Disperse the lignosulfonate in 0.2M sodium hydroxide solution to prepare a dispersion liquid with a mass fraction of 40%, mix with the epoxy-modified polyethylene glycol obtained in the previous step, and continue to react for 6 hours. After the reaction is completed, it is cooled to room temperature, the pH value of the solution is adjusted to neutrality with dilute hydrochloric acid, and unreacted impurities are removed by continuous extraction with butanone, and the product is dried to obtain the product lignin-grafted polyethylene glycol.

[0040] 3) Disp...

Embodiment 3

[0043]1) After 15 grams of polyethylene glycol was weighed and melted completely at 55°C, 0.1 gram of catalyst boron trifluoride ether was added, and then 3 ml of epichlorohydrin was added dropwise at a speed of 0.8 mL / min, and the reaction was carried out for 5 hours. After completion of the reaction, excess epichlorohydrin was removed by distillation to obtain epoxy-modified polyethylene glycol.

[0044] 2) Disperse the lignosulfonate in 0.12M sodium hydroxide solution to prepare a dispersion liquid with a mass fraction of 20%, mix with the epoxy-modified polyethylene glycol obtained in the previous step, and continue to react for 5 hours. After the reaction is completed, it is cooled to room temperature, the pH value of the solution is adjusted to neutrality with dilute hydrochloric acid, and unreacted impurities are removed by continuous extraction with butanone, and the product is dried to obtain the product lignin-grafted polyethylene glycol.

[0045] 3) Disperse 4 g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com