Ionized sulfonated polyether-ether-ketone diaphragm as well as preparation method and application thereof

A sulfonated polyether ether ketone and ionization technology, which is applied in the field of ionized sulfonated polyether ether ketone membrane and its preparation, can solve the problems of battery energy efficiency reduction, etc., and achieve reduced surface resistance, improved ion exchange capacity, and excellent The effect of ion selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preferred preparation process of the present invention is as follows:

[0041] 1, preparation of sulfonated polyether ether ketones

[0042] (1) Add a quantity of 98 wt% of concentrated sulfuric acid to the reactor, stir the stir, and open the heated to the reaction temperature;

[0043] (2) A weight after drying polyether ether ketone powder is uniformly slowly added to a concentrated sulfuric acid reactor having a 98 wt% in the range of 10 to 80 min, and the reaction is stirred under constant temperature;

[0044] (3) The reaction product of step (2) is uniformly added to the washing vessel having deionized water in the range of 5 to 50 min, and the reaction product is washed to the pH to be neutralized with deionized water. Drying the dry sulfonated polyether ether ketone solid in the oven;

[0045] (4) The dry sulfonated polyether ether ketone obtained by step (3) and the high boiling organic solvent is added to the reactor in a ratio of 1 / 30 to 1 / 3, at 50 ° C ~ 100 °...

Embodiment approach

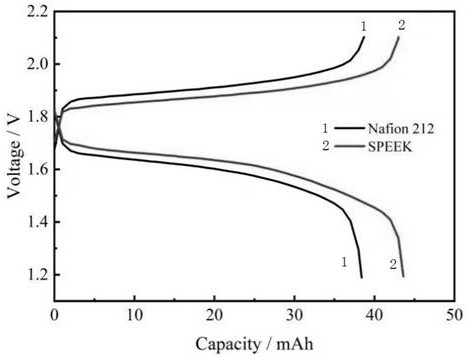

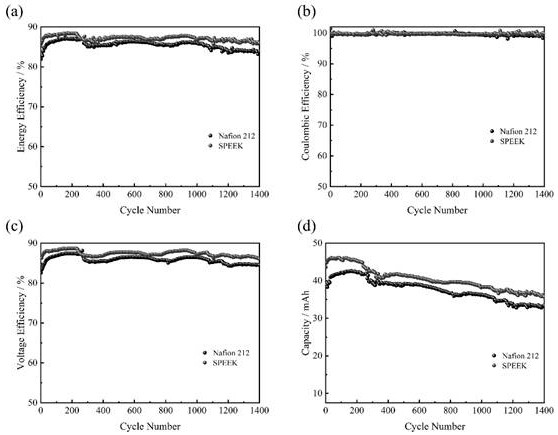

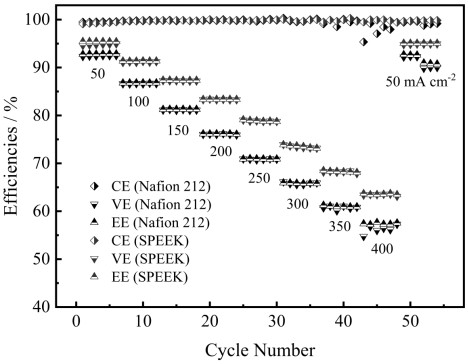

[0052] According to a third embodiment of the present invention, there is provided an application of the ionized sulfhyd polyether ether ketone compact membrane in a liquid flow battery.

[0053] The liquid flow cell of the present invention is an oxidative liquid flow battery, a particularly zinc iron flow battery, and a neutral iron sulfur flow battery.

[0054] According to a fourth embodiment of the present invention, a liquid flow battery is provided, and is formed from a positive electrode, an anode, an electrolyte, an ion exchange membrane, and the ion exchange membrane is the ionized sulfhyd polyether ether ketone diaphragm.

[0055] In order to enable those skilled in the art more apparent to the technical solutions of the present invention, the technical solutions of the present invention will be described in detail below.

Embodiment 1

[0057] 1. Preparation of sulfonated polyether ether ketogenesis

[0058] (1) 98 wt% of 12 l was added to the reactor, and stirred at 300 n / min, and the heating was opened to raise the temperature in the reactor to 63 ° C.

[0059] (2) The dried polyether ether ketone powder was uniformly added in 40 min in 40 min, and the concentrated rate of concentrated sulfate of 500 n / min continued to react at a constant temperature of 63 ° C. 2 h.

[0060] (3) Complement the reaction product of step (2) in a uniformly and slowly adding the washing vessel containing 7 ° C deionized water, and the water is rinsed with deionized water, and the reaction product is washed to the pH. Neutral, and drying the dried sulfonated polyether ether ketone solid was dried under the oven at 90 ° C.

[0061] (4) The mixed sulfonated polyether ether ketone obtained by step (3) and the dimethyl sulfoxide is added to the reactor in a ratio of 1: 6, and dissolved under a constant temperature conditions at 70 °...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ion exchange capacity | aaaaa | aaaaa |

| Ion exchange capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com