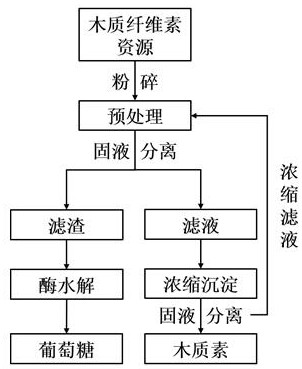

Method for comprehensively utilizing lignocellulose by using polyol-based acidic eutectic solvent

A technology of lignocellulose and deep eutectic solvent, which is applied in fermentation and other directions, can solve the problems of increased post-processing costs, etc., and achieve the effects of simple operation, improved enzymatic hydrolysis and saccharification efficiency, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

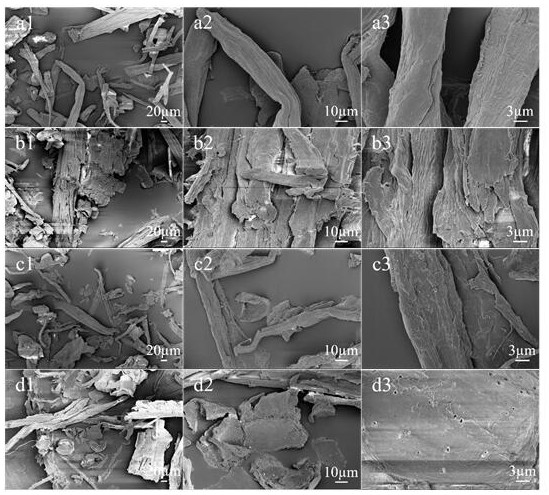

[0030] Step (1): Crushing the moso bamboo raw material to a particle size of 60-80 meshes, extracting with a 2:1 toluene-ethanol solution, and drying at a constant temperature of 65°C.

[0031] Step (2): according to molar ratio polyol:choline chloride=2:1, gross mass is that 30g takes by weighing ethylene glycol / glycerol / xylitol / sorbitol respectively (respectively denoted as embodiment 1a, implementation Example 1b, Example 1c, Example 1d) and choline chloride were in a three-necked flask, reacted at 120° C. with a stirring speed of 150 rpm until a solution was formed and was clear and transparent, and then added 0.3 g of sulfuric acid (98%) to react for 10 min .

[0032] Step (3): Weigh 3.0 g of the raw material to remove the extract in step (1) and add it to the deep eutectic solvent system configured in step (2), and react at 120° C. with a stirring speed of 150-500 rpm for 3.0 h.

[0033] Step (4) Filter the mixture in step (3) under reduced pressure, wash with excess ab...

Embodiment 2

[0038] Step (1): Crushing the moso bamboo raw material to a particle size of 60-80 meshes, extracting with a 2:1 toluene-ethanol solution, and drying at a constant temperature of 65°C.

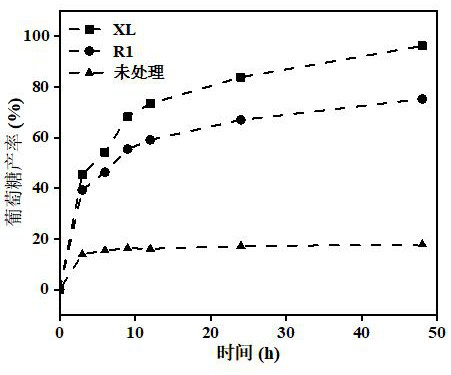

[0039] Step (2): Weigh 9.436g, 20.564g xylitol and choline chloride respectively in a three-necked flask, react at 100°C with a stirring speed of 150rpm, until a solution is formed and is clear, then add 0.3g of sulfuric acid (98 %) to react for 10 minutes.

[0040] Step (3): Weigh 3.0 g of the raw material to remove the extract from step (1) and add it to the deep eutectic solvent system configured in step (2), and react at 90° C. with a stirring speed of 150 rpm for 3.0 h.

[0041]Step (4): filter the mixture in step (3) under reduced pressure, wash with excess ethanol until the washing liquid is neutral, and collect the filtrate. The ethanol in the filtrate was removed by rotary evaporation, and then injected into ten times the volume of deionized water to obtain regenerated lignin.

[00...

Embodiment 3

[0046] Step (1): Crushing the moso bamboo raw material to a particle size of 60-80 meshes, extracting with a 2:1 toluene-ethanol solution, and drying at a constant temperature of 65°C.

[0047] Step (2): Weigh 9.436g, 20.564g xylitol and choline chloride respectively in a three-necked flask, react at 120°C with a stirring speed of 150rpm, until a solution is formed and is clear and transparent, then add 0.09g of sulfuric acid (98 %) to react for 10 minutes.

[0048] Step (3): Weigh 3.0 g of the raw material to remove the extract from step (1) and add it to the deep eutectic solvent system configured in step (2), and react at 120° C. with a stirring speed of 150 rpm for 3.0 h.

[0049] Step (4): filter the mixture in step (3) under reduced pressure, wash with excess ethanol until the washing liquid is neutral, and collect the filtrate. The ethanol in the filtrate was removed by rotary evaporation, and then injected into ten times the volume of deionized water to obtain regener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com