High-temperature softening resistant Cu-Ni-Sn series high-strength and high-elasticity copper alloy and preparation method thereof

A cu-ni-sn, copper alloy technology is applied in the field of Cu-Ni-Sn series high-strength and high-elasticity copper alloy and its preparation, which can solve problems such as unfavorable industrial production, energy saving and consumption reduction, and improve the insufficient softening resistance at high temperature. , Eliminate micro and macro segregation, and improve the effect of segregation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

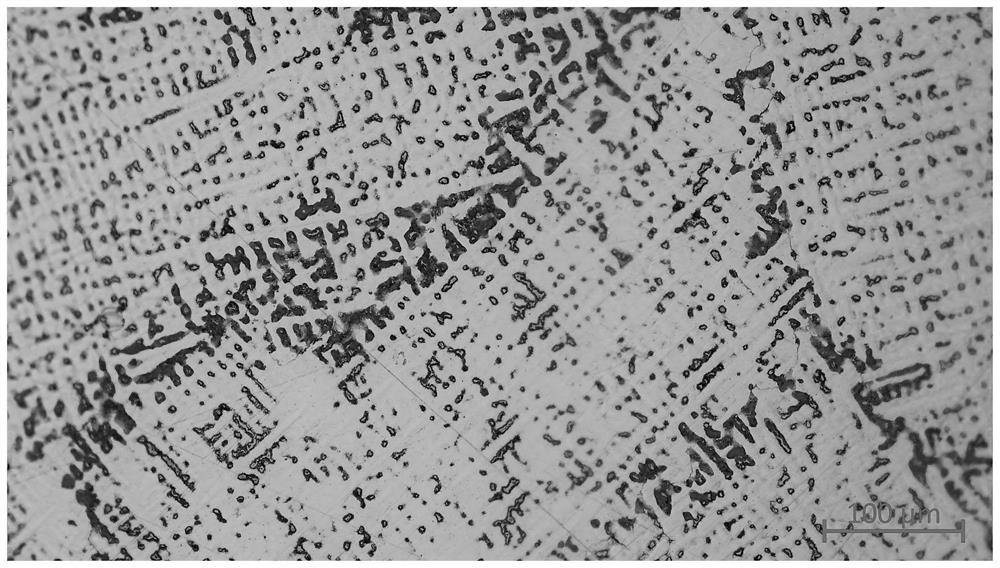

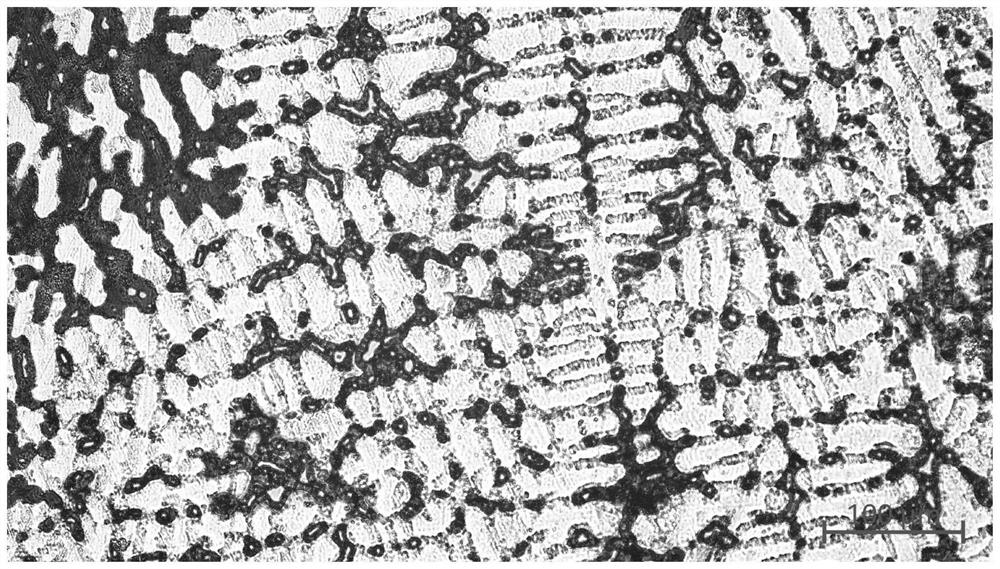

Image

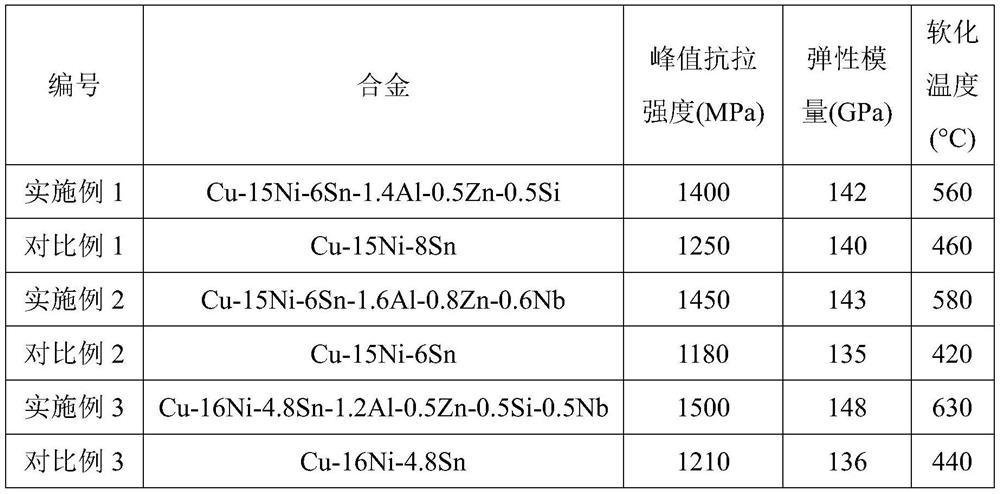

Examples

Embodiment 1

[0048] Step 1. According to the alloy composition: 15wt.% Ni, 6wt.% Sn, 1.4wt.% Al, 0.5wt.% Zn, 0.5wt.% Si, and the balance is pure copper. Among them, the purity of Ni, Sn, Al, Zn, Si is 99.95wt.%. Put the prepared copper into the smelting crucible, put Ni, Sn, Al, commercially available Cu-5Zn intermediate alloy and Si elements on the feeding tray respectively; start smelting, when the pure copper is completely melted, put in pure nickel block, And add the covering agent mixture of high-quality charcoal and graphite flakes. At this time, the temperature is controlled at 1200-1300 ° C. When the pure nickel block is completely melted, keep it warm for 5-8 minutes, and fill the melt with argon or nitrogen to stir and remove it. Then add Si, Al, Sn, and Cu-Zn master alloy in sequence, after holding the temperature for 3 to 5 minutes, lower the temperature of the melt to 1150°C to prepare for upward continuous casting.

[0049] Step 2, using boron nitride material as the crystal...

Embodiment 2

[0055] Step 1. According to the alloy composition: 15wt.% Ni, 6wt.% Sn, 1.6wt.% Al, 0.8wt.% Zn, 0.6wt.% Nb, and the balance is pure copper. Among them, the purity of Ni, Sn, Al, Zn, and Nb is 99.95wt.%. Put the prepared copper into the melting crucible, put Ni, Sn, Al, Cu-5Zn intermediate alloy and Nb elements on the feeding tray respectively; start melting, when the pure copper is completely melted, put in pure nickel block, and add The covering agent mixture of high-quality charcoal and graphite flakes. At this time, the temperature is controlled at 1200-1300 ° C. When the pure nickel block is completely melted, keep it warm for 5-8 minutes, and fill it with nitrogen or argon to stir and degas the melt; Then add Nb, Al, Sn, and Cu-Zn intermediate alloy in sequence, after 3-5 minutes of heat preservation, the temperature of the melt is lowered to 1160°C to prepare for upward continuous casting.

[0056] Step 2, using boron nitride material as the crystallizer material, using...

Embodiment 3

[0061] Step 1, according to the alloy composition: 15wt.% of Ni, 4.8wt.% of Sn, 1.2wt.% of Al, 0.5wt.% of Zn, 0.5wt.% of Si, 0.5wt.% of Nb, remaining The amount is pure copper. Among them, the purity of Ni, Sn, Al, Zn, Si and Nb is 99.95wt.%. Put the prepared copper into the smelting crucible, put Ni, Sn, Al, Cu-Zn intermediate alloy, Si and Nb elements on the feeding tray respectively; start smelting, when the pure copper is completely melted, put in the pure nickel block, And add the covering agent mixture of high-quality charcoal and graphite flakes. At this time, the temperature is controlled at 1200-1300 °C. When the pure nickel block is completely melted, keep it warm for 5-8 minutes, and fill it with argon gas to stir and degas the melt. ; Then add Nb, Si, Al, Sn, and Cu-10Zn master alloy in sequence, keep the temperature for 3 to 5 minutes, and then lower the temperature of the melt to 1150°C to prepare for upward continuous casting.

[0062] Step 2, using boron nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com