Non-noble metal catalyst for glycerin oxidation assisted hydrogen production

A non-precious metal and catalyst technology, applied in the field of materials, can solve the problems of restricting large-scale production, high cost, scarcity and poor stability, and achieve the effects of good charge conductivity, easy operation and low preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

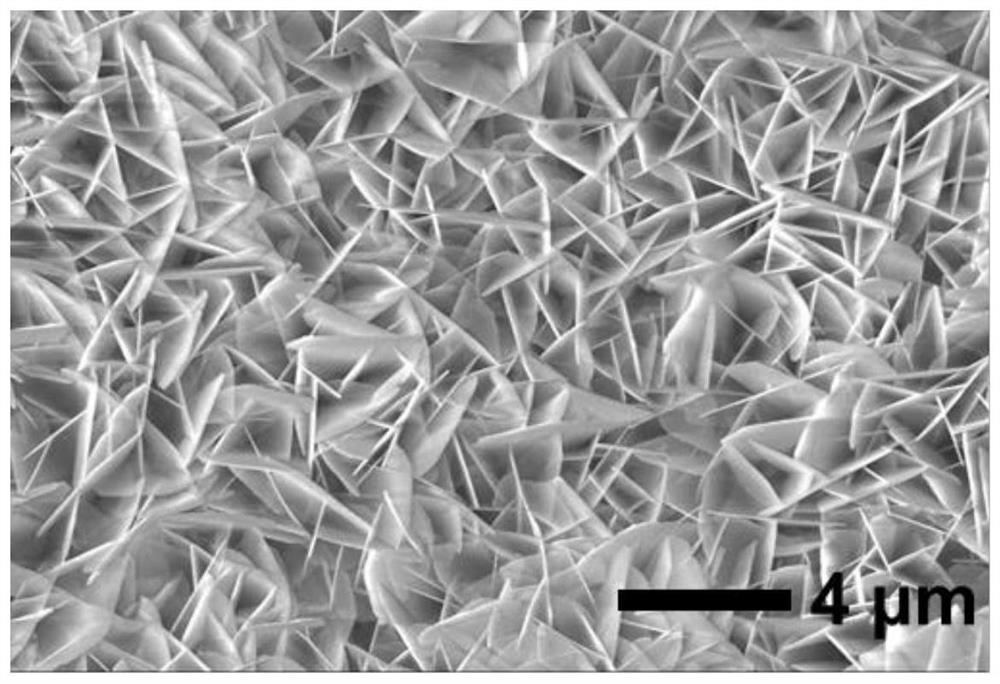

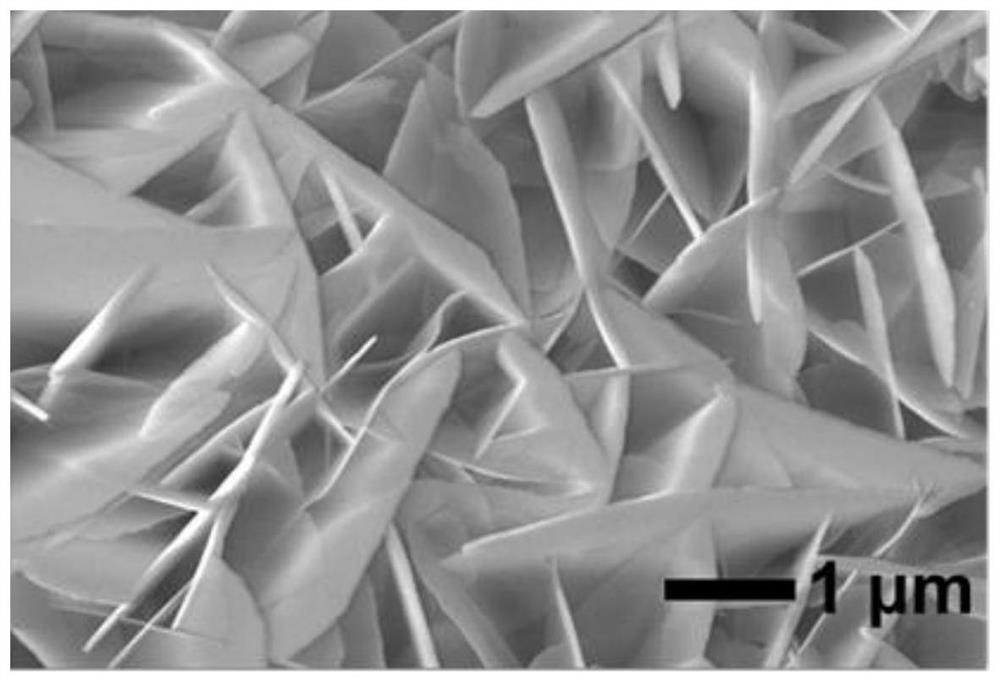

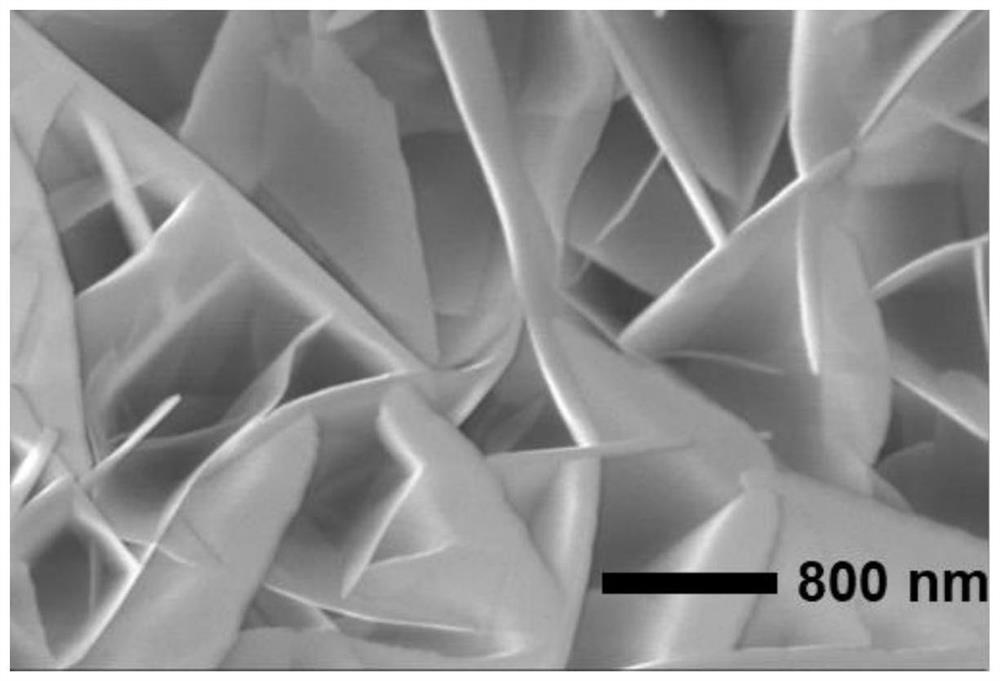

Image

Examples

Embodiment 1

[0042] 1. Pretreatment of nickel foam

[0043] Cut the foamed nickel into a size of 2cm×3cm, and then put the foamed nickel cut into 3M hydrochloric acid, absolute ethanol and deionized water for 10 minutes respectively;

[0044] 2. Preparation of Co 3 o 4 @NF

[0045] Dissolve 4.365g of cobalt nitrate hexahydrate and 0.164g of 2-methylimidazole in 20ml of methanol respectively to obtain solution A and solution B. After stirring evenly, place liquid A under a magnetic stirrer, and pour liquid B into liquid A , and stirred for 3-5min to obtain solution C evenly. The solution C and the treated foamed nickel were put into a reaction vessel together, and subjected to hydrothermal reaction at 140°C for 12h, then washed with methanol and absolute ethanol three times, and vacuum-dried at 70°C for 12h to obtain a precursor. Finally, put the dried precursor in a porcelain boat, and then place it in a high-temperature tube furnace to raise the temperature to 350°C at a rate of 2°C p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com