Preparation method of Cu-GN metal nanosheet electrocatalyst

A metal nano, electrocatalyst technology, applied in metal processing equipment, nano carbon, nano technology and other directions, can solve problems such as high energy consumption, and achieve the effect of improving electrical conductivity, mild conditions and less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

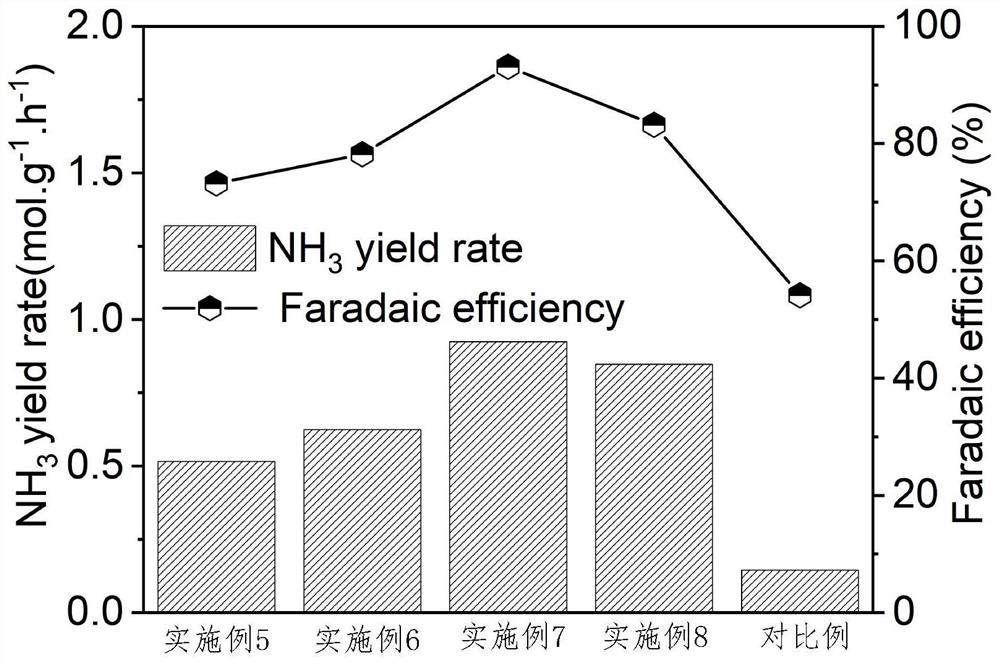

Examples

Embodiment 1

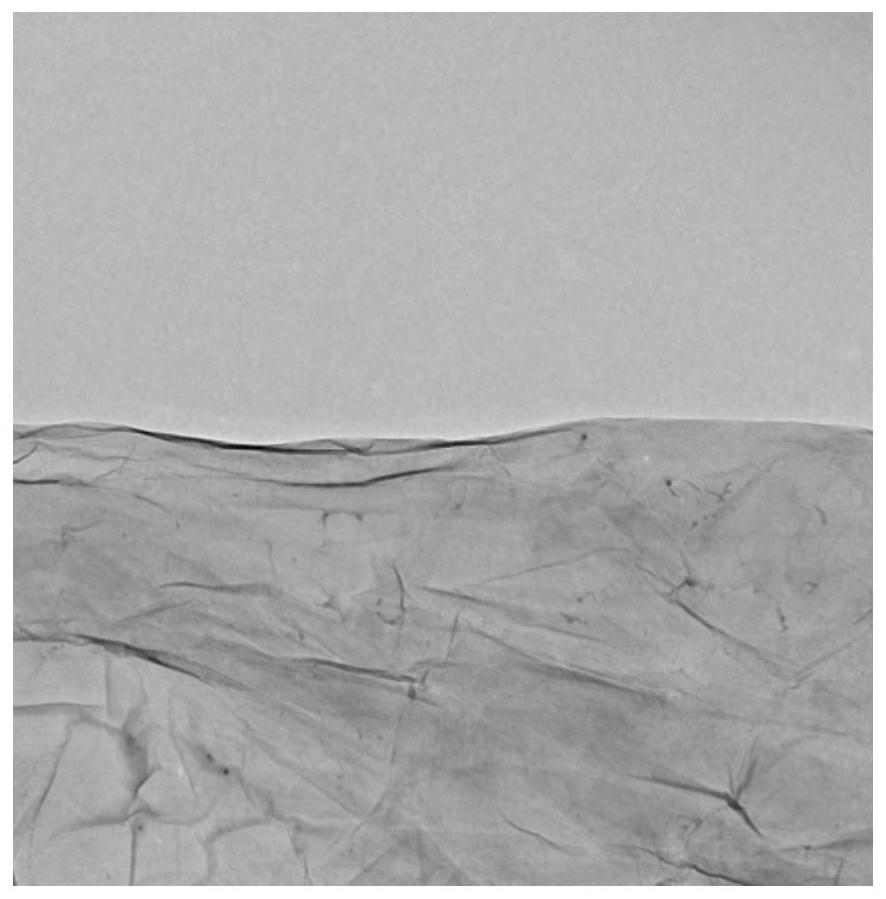

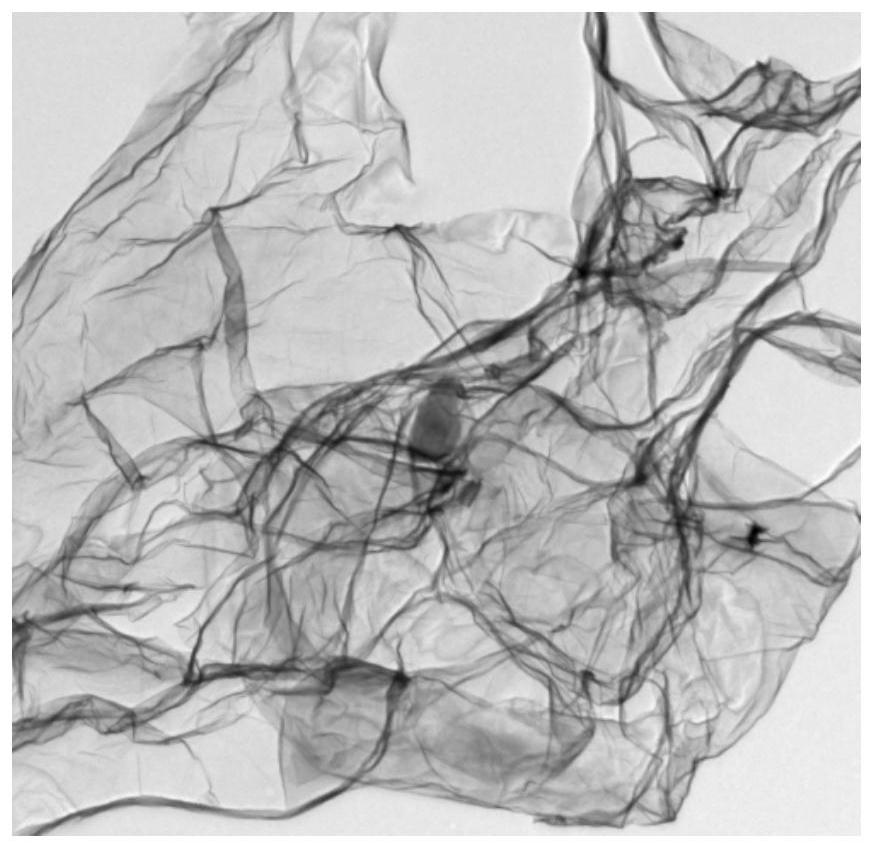

[0019] Step (1) the graphene oxide dispersion liquid that concentration is 2g / L is melted in deionized water, forms the first solution; The volume ratio of graphene oxide dispersion liquid and deionized water is 1:0.5;

[0020] Step (2) According to the addition ratio of 10 grams per liter, copper chloride dihydrate is added to the first solution, and ultrasonic 30min is formed to form the second solution;

[0021] Step (3) Freeze the second solution in liquid nitrogen for 10 minutes, and then transfer it to a freeze dryer for 96 hours;

[0022] Step (4) moving the freeze-dried product into a tube furnace, and calcining for 4h under an ammonia atmosphere at 600°C;

[0023] Step (5) Add deionized water, isopropanol, and naphthol solution to the calcined product in sequence, and the addition ratio is 150 ml of deionized water, 80 ml of isopropanol, and 12 ml of naphthol solution per gram of product, and ultrasonically for 30 minutes , to obtain Cu-GN metal nanosheet electrocata...

Embodiment 2

[0025] Step (1) the graphene oxide dispersion liquid that concentration is 3g / L is melted in deionized water, forms the first solution; The volume ratio of graphene oxide dispersion liquid and deionized water is 1:0.8;

[0026] Step (2) According to the addition ratio of 100 grams per liter, copper chloride dihydrate is added to the first solution, and ultrasonic 60min is formed to form the second solution;

[0027] Step (3) freezing the second solution in liquid nitrogen for 30 minutes, and then transferring it to a freeze dryer for 48 hours;

[0028] Step (4) moving the freeze-dried product into a tube furnace, and calcining at 800°C for 2h under an ammonia atmosphere;

[0029] Step (5) Add deionized water, isopropanol, and naphthol solution to the calcined product successively, and the addition ratio is 200 milliliters of deionized water, 65 milliliters of isopropanol, and 15 milliliters of naphthol solution per gram of product, and ultrasonication for 60 minutes , to obta...

Embodiment 3

[0031] Step (1) the graphene oxide dispersion liquid that concentration is 2.5g / L is melted in deionized water, forms the first solution; The volume ratio of graphene oxide dispersion liquid and deionized water is 1:0.3;

[0032] Step (2) According to the addition ratio of 50 grams per liter, copper chloride dihydrate was added to the first solution, and the ultrasonic wave was used for 20 minutes to form a second solution;

[0033] Step (3) Freeze the second solution in liquid nitrogen for 20 minutes, then transfer it to a freeze dryer for 60 hours;

[0034] Step (4) moving the freeze-dried product into a tube furnace, and calcining for 3 hours in an ammonia atmosphere at 700°;

[0035] Step (5) Add deionized water, isopropanol, and naphthol solution to the calcined product successively, and the addition ratio is 180 milliliters of deionized water, 50 milliliters of isopropanol, and 10 milliliters of naphthol solution per gram of product, and ultrasonically for 20 minutes , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com