Solar energy conversion material, solar cell encapsulant comprising same, and solar cell comprising same

A solar energy conversion and solar cell technology, which is applied in luminescent materials, circuits, photovoltaic power generation, etc., can solve the problems of interfering with solar cell light absorption, reducing the initial output of solar cell modules, reducing the overall output of solar cells or solar cell modules, etc. Guaranteed long-term output, reduced power generation cost, high output and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0132] Preparation Example 1: Preparation of solar energy conversion material (aluminum hydroxide precursor)

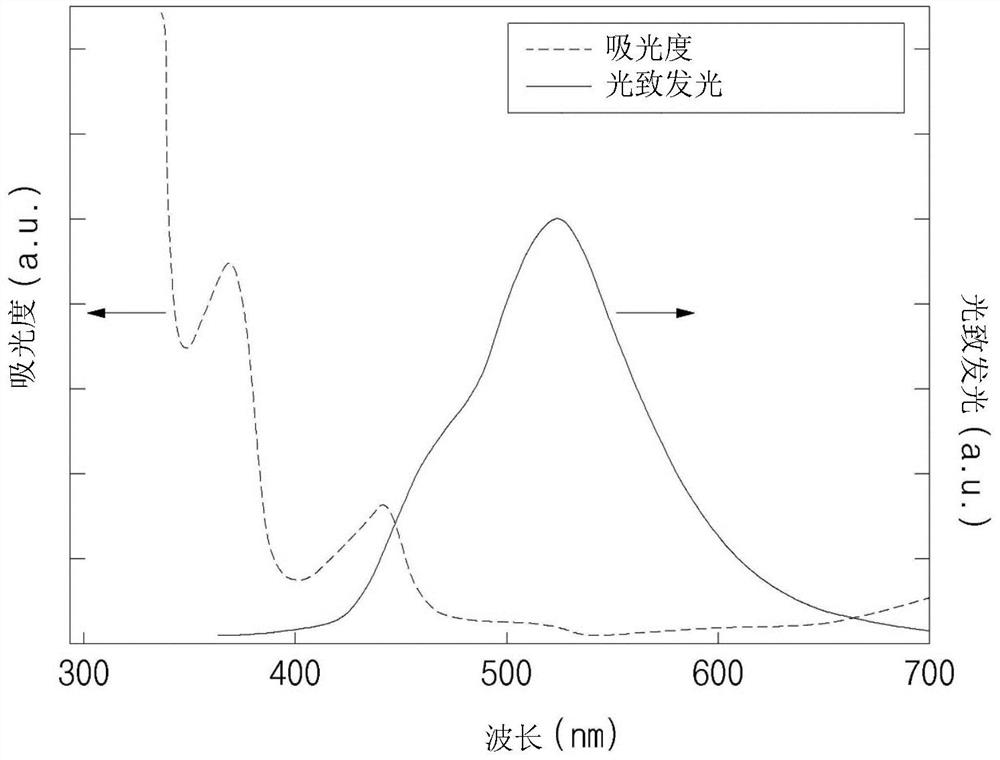

[0133] 10 g of aluminum acetate was mixed with 100 ml of 1-octadecene solvent, and then thermal decomposition reaction was performed at 300° C. with stirring for 30 minutes. After the reaction was completed, aluminum hydroxide was separated by centrifugation and redispersed in 10 ml of toluene solvent. image 3 The UV-Vis spectrum and photoluminescence spectrum of the luminescent aluminum hydroxide solution thus prepared are shown, where the dotted line represents the absorption and the solid line represents the photoluminescence spectrum. Examples based on the aluminum hydroxide content were set as Examples 1 and 2, respectively.

preparation example 2

[0134] Preparation Example 2: Preparation of solar energy conversion materials (aluminum hydroxide precursor + lanthanide ions)

[0135] 10 g of aluminum acetate was mixed with 10 ml of 1-octadecene solvent. To this mixed solution, ytterbium(III) acetate hydrate (from the above-mentioned near-infrared emitting lanthanide ions) was added in an amount of 0.2% by weight compared to the aluminum precursor, and then heated at 300°C under stirring. The decomposition reaction was 30 minutes. After the reaction was completed, aluminum hydroxide was separated by centrifugation and redispersed in 10 ml of toluene solvent. The solar conversion material synthesized in this way was used in Example 3, and the solar conversion material synthesized without adding ytterbium(III) acetate hydrate was used in Comparative Example 5.

preparation example 3

[0136] Preparation Example 3: Preparation of solar energy conversion material (aluminum hydroxide + aromatic ring compound)

[0137] 10 g of aluminum acetate was mixed with 100 ml of 1-octadecene solvent, and then thermal decomposition reaction was performed at 300° C. with stirring for 30 minutes. After the reaction was complete, the aluminum hydroxide was separated by centrifugation and redispersed in 10 ml of toluene.

[0138] In order to control the photoluminescent properties, 3-hydroxy-2-naphthoic acid was added as an aromatic ring compound in an amount of 5 wt% compared with aluminum acetate as an aluminum precursor, and the Thermal decomposition reaction for 30 minutes, then separation and purification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com