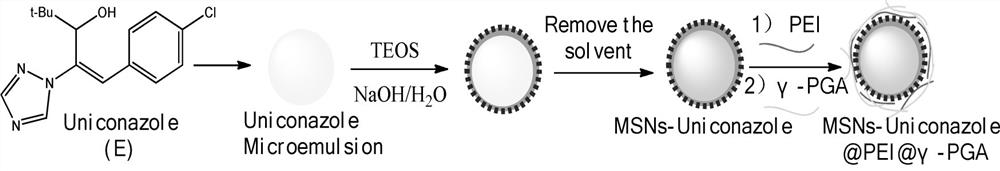

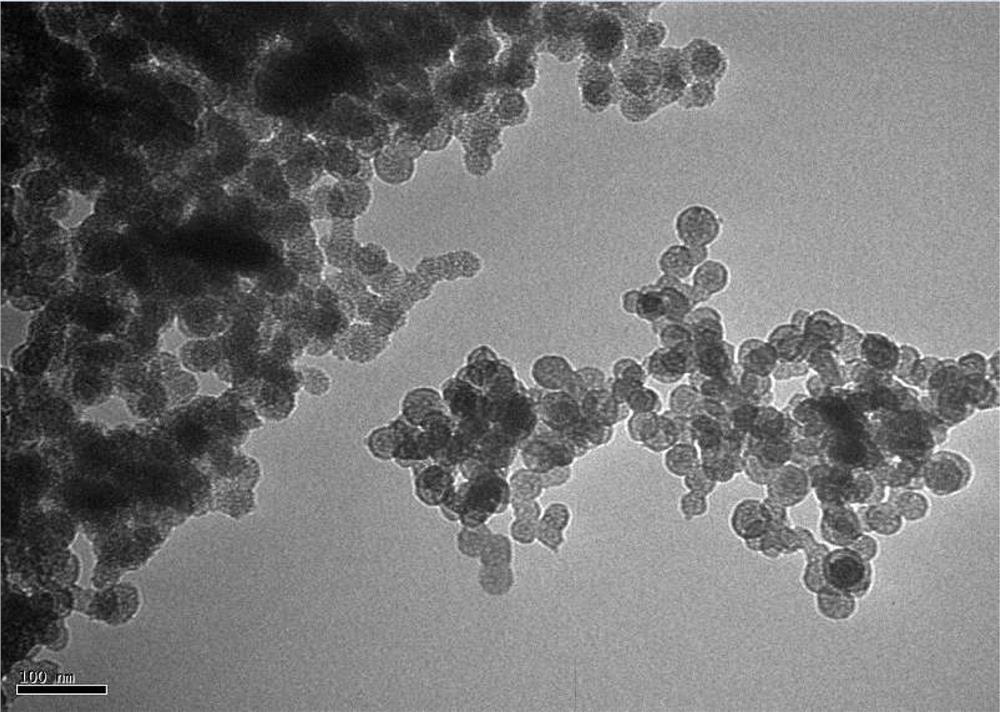

Preparation method of mesoporous silica nano double-layer microsphere controlled release agent

A technology of mesoporous silica and nano-microspheres, applied in botany equipment and methods, biocides, fungicides, etc., can solve the problems of poor target adsorption permeability, poor solubility, drug loss, etc., and achieve good biocompatibility and degradability, low viscosity, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

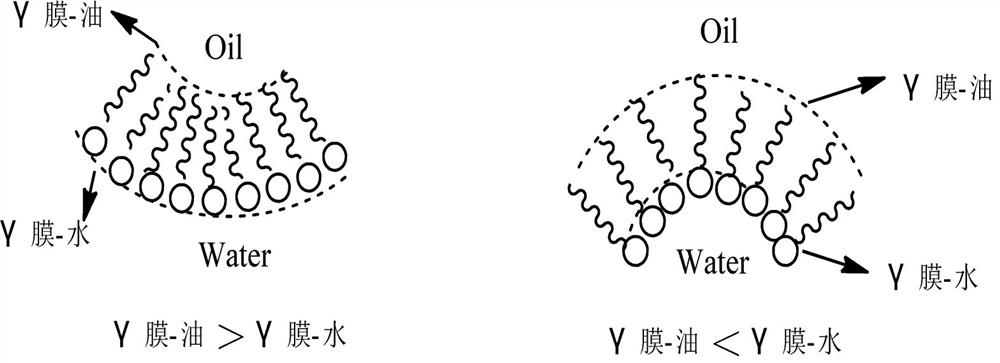

Method used

Image

Examples

Embodiment 1

[0034] Weigh 12g of uniconazole, add 35g of ethyl acetate and 20g of cetyltrimethylammonium bromide successively

[0035] (CTAB), 13.5g isobutanol and 2g ethylene glycol, 45°C, 400 r / min, keep stirring for 30min, under stirring, add 17.5g pure water at a drop rate of 1.0 mL / min, and keep stirring for 15min to obtain ene Put the microemulsion of clobutrazol in the cold, let it stand to observe the clarification of the microemulsion, and stand it at -5°C (refrigerated), room temperature and 54°C (hot storage) for 48 hours to observe the change of the microemulsion.

Embodiment 2

[0037] Weigh 12g uniconazole, add 35g N,N -Dimethylformamide, 20g cetyltrimethyl bromide

[0038] Ammonium chloride (CTAB), 13.5g of isobutanol and 2g of ethylene glycol, 45°C, 400 r / min, continue to stir for 30min, under stirring, add 17.5g of pure water at a drop rate of 1.0 mL / min, and continue to stir for 15min to prepare The uniconazole microemulsion was obtained, let it cool, and observed the clarification of the microemulsion, and then stood it at -5°C (refrigerated), room temperature and 54°C (hot storage) for 48 hours to observe the change of the microemulsion.

Embodiment 3

[0040] Weigh 12g uniconazole, add 35g cyclohexanone, 20g cetyltrimethylammonium bromide successively

[0041] (CTAB), 13.5g isobutanol and 2g ethylene glycol, 45°C, 400 r / min, keep stirring for 30min, under stirring, add 17.5g pure water at a drop rate of 1.0 mL / min, and keep stirring for 15min to obtain ene Put the microemulsion of clobutrazol in the cold, let it stand to observe the clarification of the microemulsion, and stand it at -5°C (refrigerated), room temperature and 54°C (hot storage) for 48 hours to observe the change of the microemulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com