Waste acid cyclic regeneration on-line recovery treatment system and process

A recovery treatment and regeneration system technology, applied in the direction of metallurgical wastewater treatment, sludge treatment, filtration treatment, etc., can solve the problems of complex treatment process, complex process, easy-to-corrosion equipment, etc., to achieve improved removal efficiency, short process flow, and technical advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

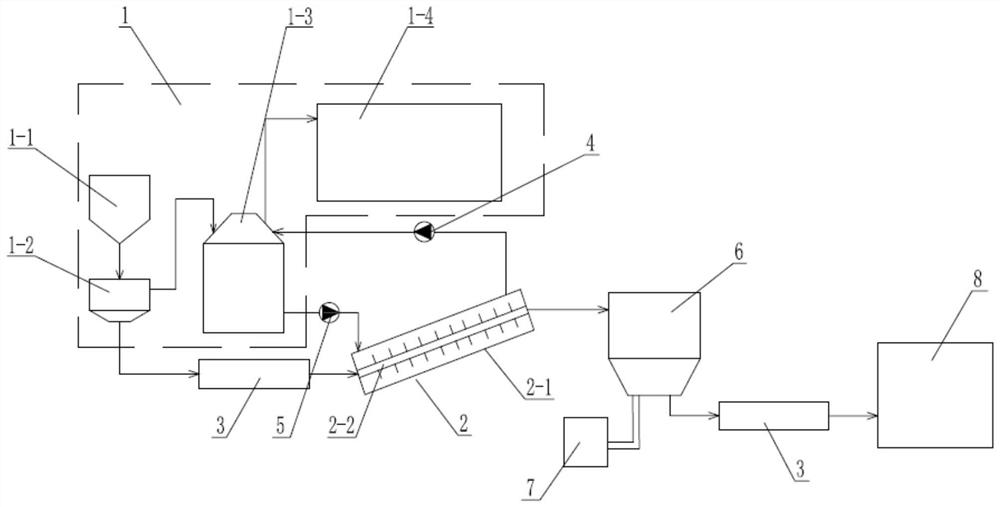

[0044] The specific steps of the waste acid recycling online recycling process are as follows:

[0045] Step 1: The waste acid washing liquid is processed in the waste acid regeneration system 1 to make acid.

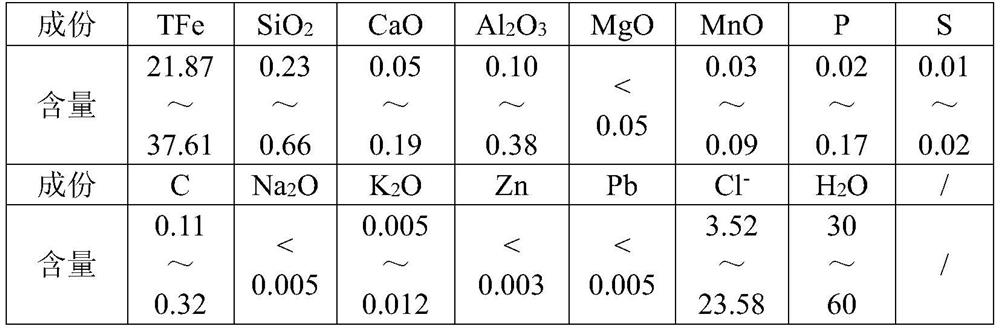

[0046] Specifically, firstly, the waste acid solution is introduced into the sedimentation tank 1-1, and the sedimentation tank 1-1 performs primary filtration after the impurities in the waste acid solution are precipitated, and the supernatant is subjected to pressure filtration again through the filter press 1-2 After the plate and frame filter press completes the set pressure, increase the air pressure of the tympanic membrane (1.0MPa-2.0MPa) to further reduce the liquid content in the sludge and reduce the water content to 30% to 60%. The main chemical composition of the product is shown in Table 1; then, after the waste acid liquid after the secondary filtration is collected, it enters the roaster 1-3 for high-temperature roasting, and the temperature of the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com