Hyaluronic acid-astaxanthin nano-composite as well as preparation method and application thereof

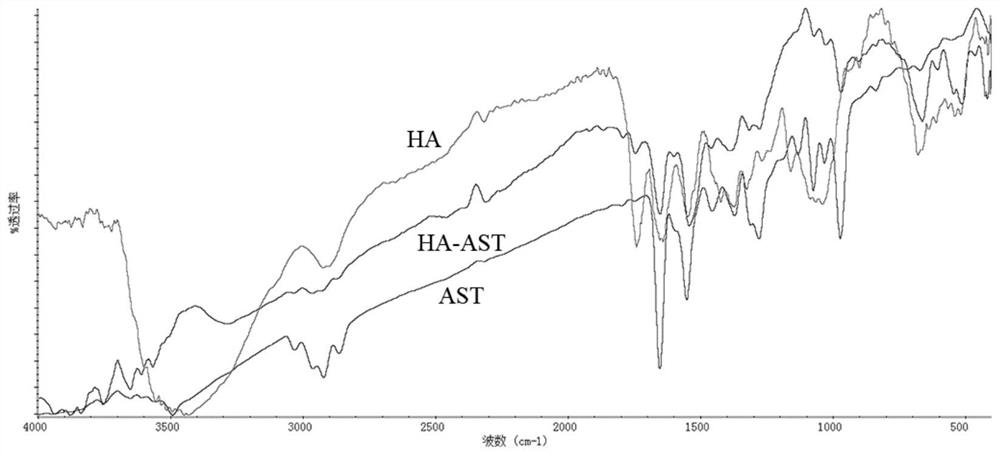

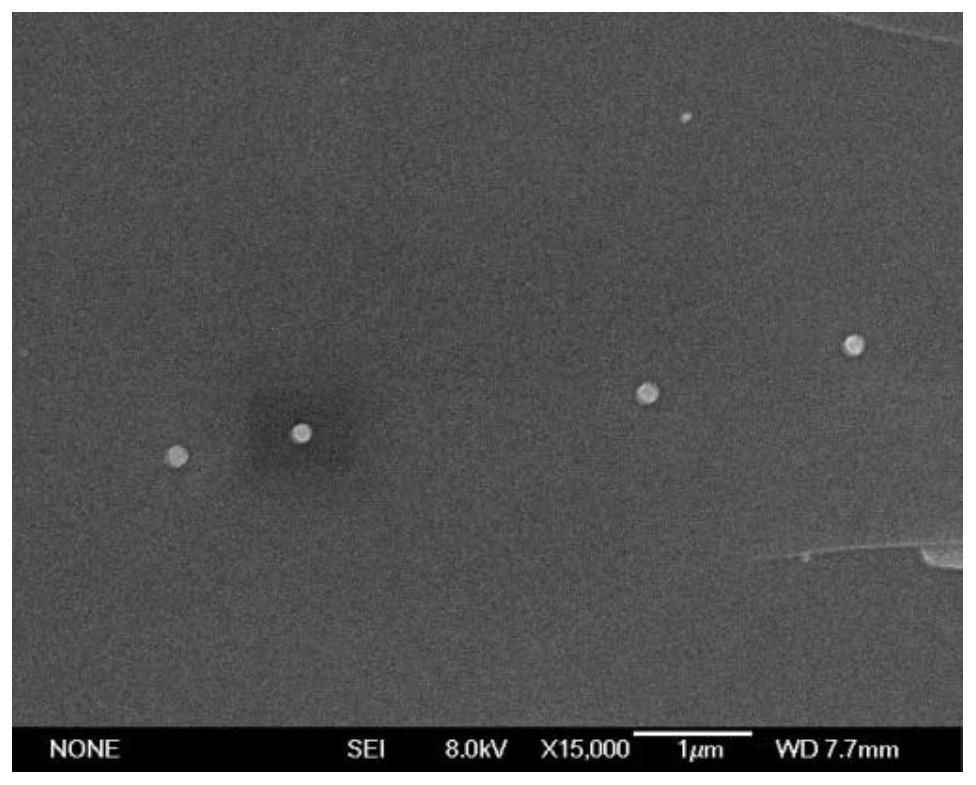

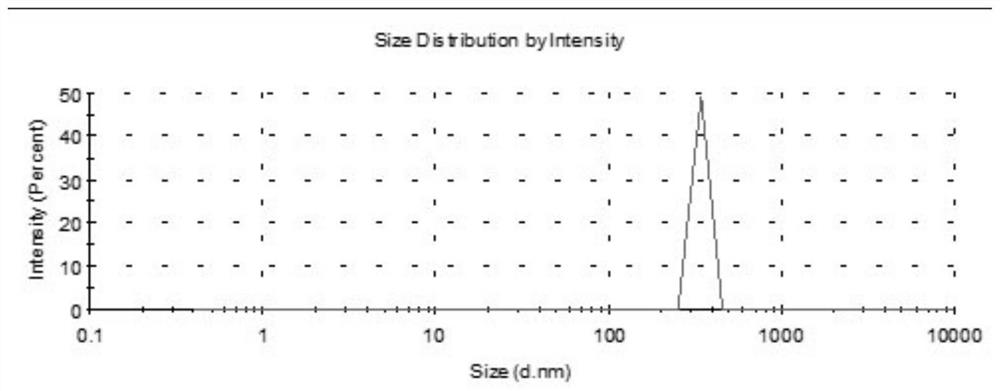

A nano-composite, hyaluronic acid technology, applied in application, drug combination, animal feed, etc., can solve the problem of instability of astaxanthin, achieve good biocompatibility, improve stability, and solve the effect of easy oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Add 4mmol of cross-linking agent N-hydroxysuccinimide and 8mmol of hyaluronic acid into 500mL of dimethyl sulfoxide, ultrasonically dissolve at 50°C, stir at room temperature for 10min, and then add 0.5mmol of ethylenediamine under nitrogen protection, at 50°C After reacting for 12 hours, the reaction mixture was slowly poured into 30 mL of sodium hydroxide solution, and a dialysis bag with a molecular weight cut-off of 3500 Da was used for dialysis to remove impurities. The dialysis solvent and time were successively: 0.01 M NaOH dialysis for 5 hours, acetonitrile: water (1 : 1, V / V) dialyzed for 24h, distilled water dialyzed for 72h, after the end of the dialyzed, freeze-dried to obtain ethylenediamine hyaluronic acid.

[0042] Dissolve 1mmol of ethylenediamine hyaluronic acid in 10mL of sodium acetate buffer solution with a pH value of 5, then add 1mmol of astaxanthin dissolved in 2mL of ethanol, heat and stir at 50°C for 3d under a nitrogen atmosphere, and adopt a mo...

Embodiment 2

[0047] Add 2.5mmol of cross-linking agent N-hydroxysuccinimide and 5mmol of hyaluronic acid into 500mL of dimethyl sulfoxide, ultrasonically dissolve at 50°C, add 14mmol of dichloroethane, stir at room temperature for 10min, and then add 0.5mL under nitrogen atmosphere mmol ethylenediamine, react at 80°C for 2 days, use a dialysis bag with a molecular weight cut-off of 3500Da to carry out dialysis, remove the reaction solution, the dialysis solvent and time are sequentially: 0.01M NaOH dialysis for 8 hours, acetonitrile: water (1:1, V / V) Dialysis for 20 hours, dialysis with distilled water for 55 hours, and freeze-drying to obtain ethylenediamine hyaluronic acid after dialysis.

[0048] Dissolve 5mmol ethylenediamine hyaluronic acid in 10mL sodium acetate buffer solution with a pH value of 5, then add 1mmol astaxanthin dissolved in 2mL dioxane, heat and stir at 50°C for 3d under a nitrogen atmosphere, and use interception A dialysis bag with a molecular weight of 3500 Da was ...

Embodiment 3

[0051] Add 5mmol of cross-linking agent N-hydroxysuccinimide and 10mmol of hyaluronic acid into 500mL of dimethyl sulfoxide, ultrasonically dissolve at 50°C, add 14mmol of dichloroethane, stir at room temperature for 10min, and then add 0.5mmol of Ethylenediamine was reacted at 30°C for 3 days, and the dialysis bag with a molecular weight cut-off of 3500Da was used for dialysis to remove the reaction solution. The dialysis solvent and time were as follows: 0.01M NaOH dialysis for 3 hours, acetonitrile: water (1:1, V / V ) dialysis for 24 hours, distilled water dialysis for 24 hours, and freeze-drying after dialysis to obtain ethylenediamine hyaluronic acid.

[0052] Dissolve 0.5mmol ethylenediamine hyaluronic acid in 10mL sodium acetate buffer solution with a pH value of 5, then add 1mmol astaxanthin dissolved in 2mL ethanol, heat and stir at 50°C for 3d under a nitrogen atmosphere, and adopt molecular weight cut-off of A 3500Da dialysis bag was dialyzed with deionized water for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com