A kind of preparation method of environment-friendly deicing agent

A snow-melting agent and an environment-friendly technology, which is applied in the field of preparing the environment-friendly snow-melting agent, can solve the problems of increasing the cost of solid waste treatment, increasing the cost of sewage treatment, and the low purity of lactic acid, so as to solve the problem of salinization, enhance the absorption of light, The effect of improving water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

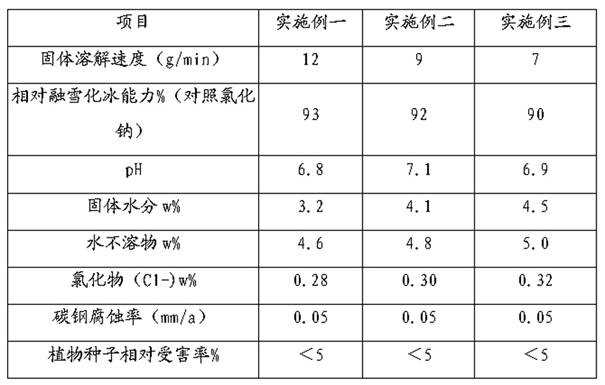

Examples

Embodiment 1

[0033] S1. Take 40L of lactic acid fermentation broth with a dry weight of 8% (w / w) of bacteria and filter and concentrate it with a 50nm ceramic membrane to obtain 35L of supernatant liquid and 5L of dense phase bacterial residue waste liquid, dense phase bacterial residue waste The dry weight of bacteria in the solution accounts for 50% (w / w), and the amount of protein in the bacteria is obtained by multiplying the quality of organic nitrogen source by 6.25, and the protein amount accounts for 40% (w / w) of the dense phase bacterial residue waste liquid;

[0034] S2. Place the 5L dense phase slag waste liquid obtained in step 1 in the acidolysis reaction kettle, add 6mol / L sulfuric acid through a peristaltic pump at 80ml / min, stir while adding, add the sulfuric acid in the reaction solution to the end The concentration is 2 mol / L, hydrolyzed for 12 hours under the condition of normal pressure 110 ℃, and the degree of hydrolysis is 72%. Then adjust the pH to the end point 7.0 ...

Embodiment 2

[0042] S1. Take 40L of lactic acid fermentation broth with a dry weight of 7% (w / w) of bacteria and filter and concentrate it with a 50nm ceramic membrane to obtain 35L of clear liquid and 5L of dense phase bacterial residue waste liquid, dense phase bacterial residue waste The dry weight of bacteria in the liquid accounts for 48% (w / w), and the protein content of the bacteria is obtained by multiplying the quality of organic nitrogen source by 6.25, and the protein content accounts for 38.4% (w / w) of the dense phase bacterial residue waste liquid;

[0043] S2. Place the 5L dense phase slag waste liquid obtained in step 1 in the acidolysis reaction kettle, add 6mol / L sulfuric acid through a peristaltic pump at 80ml / min, stir while adding, add the sulfuric acid in the reaction solution to the end Concentration 2mol / L, hydrolyzed at normal pressure 110°C for 12h, the degree of hydrolysis was 71%. Then adjust the pH to the end point 7.0 with ammonia water with a mass fraction of ...

Embodiment 3

[0050] S1. Take 40L of lactic acid fermentation broth with a dry weight of bacteria accounting for 6% (w / w) and filter and concentrate it with a 50nm ceramic membrane to obtain 35L of supernatant liquid and 5L of dense phase bacterial residue waste liquid, dense phase bacterial residue waste The dry weight of bacteria in the liquid accounts for 45% (w / w), and the amount of protein in the bacteria is obtained by multiplying the quality of organic nitrogen source by 6.25, and the protein amount accounts for 36% (w / w) of the dense phase bacterial residue waste liquid;

[0051] S2. Place the 5L dense phase slag waste liquid obtained in step 1 in the acidolysis reaction kettle, add 6mol / L sulfuric acid through a peristaltic pump at 80ml / min, stir while adding, add the sulfuric acid in the reaction solution to the end The concentration is 2 mol / L, hydrolyzed for 12 hours under normal pressure 110°C, and the detected hydrolysis degree reaches 70%. Then adjust the pH to the end point ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com