Preparation method of antibacterial textile and antibacterial textile

A technology for antibacterial textiles and fabrics, which is applied in the preparation of antibacterial textiles and in the field of antibacterial textiles, can solve the problems of large loss of fragrance, difficult application, short fragrance retention time, etc., and achieves the effect of excellent washing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

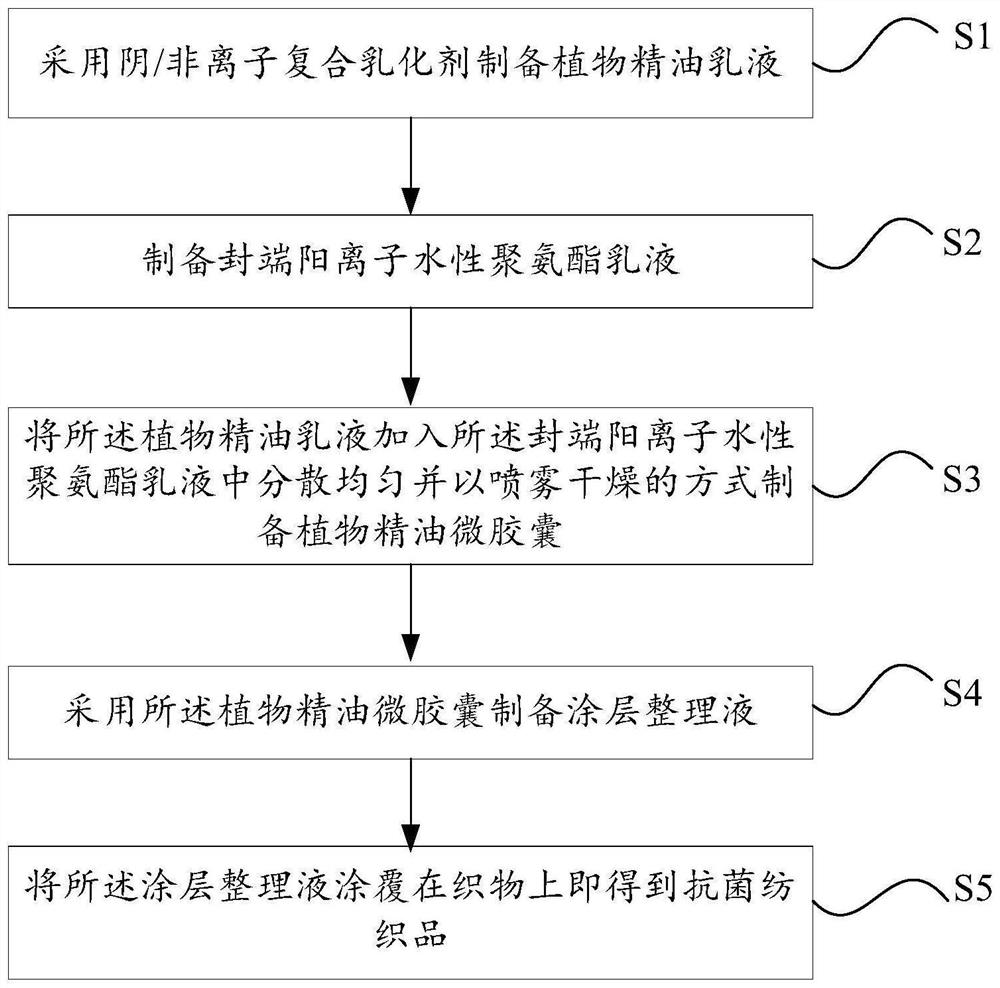

[0026] see figure 1 The invention provides a method for preparing antibacterial textiles. The textiles prepared by the method of the present invention have excellent broad-spectrum antibacterial properties against Staphylococcus aureus, Escherichia coli, Candida albicans and the like.

[0027] see figure 1 , the invention provides a kind of preparation method of antibacterial textile, comprises the following steps:

[0028] S1, using anionic / nonionic composite emulsifiers to prepare plant essential oil emulsions;

[0029] S2, preparing a blocked cationic water-based polyurethane emulsion;

[0030] S3, adding the plant essential oil emulsion into the blocked cationic water-based polyurethane emulsion to disperse evenly and prepare the plant essential oil microcapsules by spray drying;

[0031] S4, using plant essential oil microcapsules to prepare coating finishing liquid;

[0032] S5, coating the coating finishing solution on the fabric to obtain antibacterial textiles.

Embodiment 1

[0041] (1) Add Tween 80 and sodium dodecyl sulfate to deionized water at a mass ratio of 1:1, stir and dissolve to form a water phase, and then add thyme essential oil and mugwort essential oil at a mass ratio of 1:1 The compound plant essential oil was emulsified at 40°C using a high-shear dispersing emulsifier for 1 hour to obtain a stable O / W emulsion, in which the sum of the mass of Tween 80 and sodium dodecylsulfonate accounted for the mass of the compound plant essential oil 5% of

[0042] (2) Put 0.5 mol of castor oil-modified diol with a hydroxyl value of 180 mg KOH / g in a three-necked flask with temperature control, stirring and condensation devices, remove water under reduced pressure at 110°C for 1 hour, cool down to 40°C and add 0.6mol of hexamethylene diisocyanate, stirred and mixed for 20min, then added 0.5wt% (relative to the total mass of diol and isocyanate in the system) of dibutyltin dilaurate, heated to 50°C for 30min, and continued to heat up to 70°C ℃ fo...

Embodiment 2

[0047] (1) Add Tween 80 and sodium dodecylsulfonate in a mass ratio of 3:1 to deionized water, stir and dissolve to form a water phase, then add thyme essential oil and mugwort essential oil in a mass ratio of 1:3 The compound plant essential oil was emulsified at 40°C using a high-shear dispersing emulsifier for 1 hour to obtain a stable O / W emulsion, in which the sum of the mass of Tween 80 and sodium dodecylsulfonate accounted for the mass of the compound plant essential oil 10% of;

[0048] (2) Put 0.5 mol of castor oil-modified diol with a hydroxyl value of 180 mg KOH / g in a three-necked flask with temperature control, stirring and condensation devices, remove water under reduced pressure at 110°C for 2 hours, cool down to 40°C and add 0.7mol of hexamethylene diisocyanate, stir and mix for 20min, then add 1wt% (relative to the total mass of diol and isocyanate in the system) dibutyltin dilaurate, heat up to 50°C for 60min, continue to heat up to 70°C React for 60 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com