Cestite blue film composite material and preparation method thereof

A thin-film composite material, lapis lazuli blue technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of cumbersome process flow, low controllability, and high energy consumption of the external force-assisted method. Achieve the effect of improving electrical stability, performance reproducibility, and excellent uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

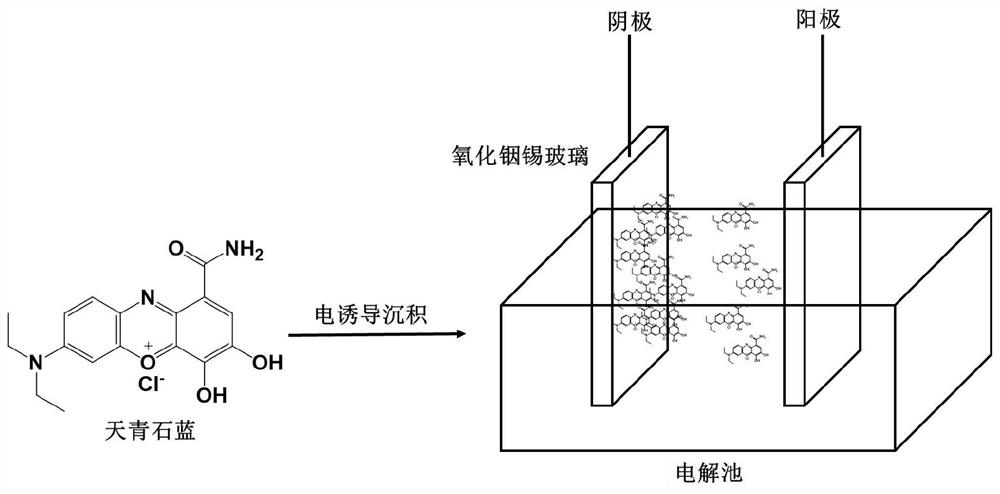

[0033] Dissolve 2 mg of azure blue molecules in 1 mL of dimethyl sulfoxide and 9 mL of acetonitrile, stir for 12 hours to fully dissolve, and finally obtain a mixed solution as a precursor for the preparation of nanofiber films;

[0034] Place the prepared precursor solution in the pre-designed 3cm 3 in the electrolytic cell. Build a closed electric field-induced deposition workstation, place the electrodes of the workstation on the left and right ends of the electrolytic cell, the electrode spacing is 1mm, then apply a voltage of 10V, and continue to deposit for 5 minutes; the lapis lazuli blue material self-assembles and deposits slowly in the electrolytic cell On the conductive indium tin oxide layer substrate 4, a layer of uniform and dense organic nanofiber film layer is obtained; then the deposited film is taken out of the electrolytic cell with a puller, and placed flat in a vacuum oven at 100°C for drying. A lapis lazuli film 3 was obtained.

[0035] at 10 -6 Under ...

Embodiment 2

[0037] Dissolve 4 mg of azure blue molecules in 1.8 mL of dimethyl sulfoxide and 18.2 mL of acetonitrile mixed, stir for 8 hours to fully dissolve, and finally obtain a mixed solution as a precursor for the preparation of nanofiber films;

[0038] Place the prepared precursor solution in the pre-designed 2cm 3 in the electrolytic cell. Build a closed electric field induced deposition workstation, place the electrodes of the workstation on the left and right ends of the electrolytic cell, the electrode spacing is 8mm, then apply a voltage of 5V, and continue to deposit for 6 minutes; the lapis lazuli blue material self-assembles and slowly deposits in the electrolytic cell On the conductive indium tin oxide layer substrate, a uniform and dense organic nanofiber film layer is obtained; then the deposited film is taken out of the electrolytic cell with a puller, and placed flat in a vacuum oven at 100°C to dry, and the obtained Lapis lazuli blue film.

[0039] at 10 -4 Under t...

Embodiment 3

[0041] Dissolve 6 mg of azure blue molecules in 3.3 mL of dimethyl sulfoxide and 26.7 mL of acetonitrile mixed, stir for 16 hours to fully dissolve, and finally obtain a mixed solution as a precursor for the preparation of nanofiber films;

[0042] Place the prepared precursor solution in the pre-designed 4cm 3in the electrolytic cell. Build a closed electric field induced deposition workstation, place the electrodes of the workstation on the left and right ends of the electrolytic cell, the electrode spacing is 12mm, then apply a voltage of 15V, and continue to deposit for 4min; the lapis lazuli blue material self-assembles and slowly deposits in the electrolytic cell On the conductive indium tin oxide layer substrate, a uniform and dense organic nanofiber film layer is obtained; then the deposited film is taken out of the electrolytic cell with a puller, and placed flat in a vacuum oven at 100°C to dry, and the obtained Lapis lazuli blue film.

[0043] at 10 -6 Under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com