Method for preparing hydrogen-rich fuel gas by catalyzing biomass tar cracking through aluminum smelting waste residues

A technology of tar cracking and aluminum waste residue, which is applied in the direction of catalyst activation/preparation, biofuels, chemical instruments and methods, etc., can solve the problems of expensive catalysts and poor hydrogen selectivity, so as to promote high-value utilization and industrialization process , the effect of increasing the hydrogen production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

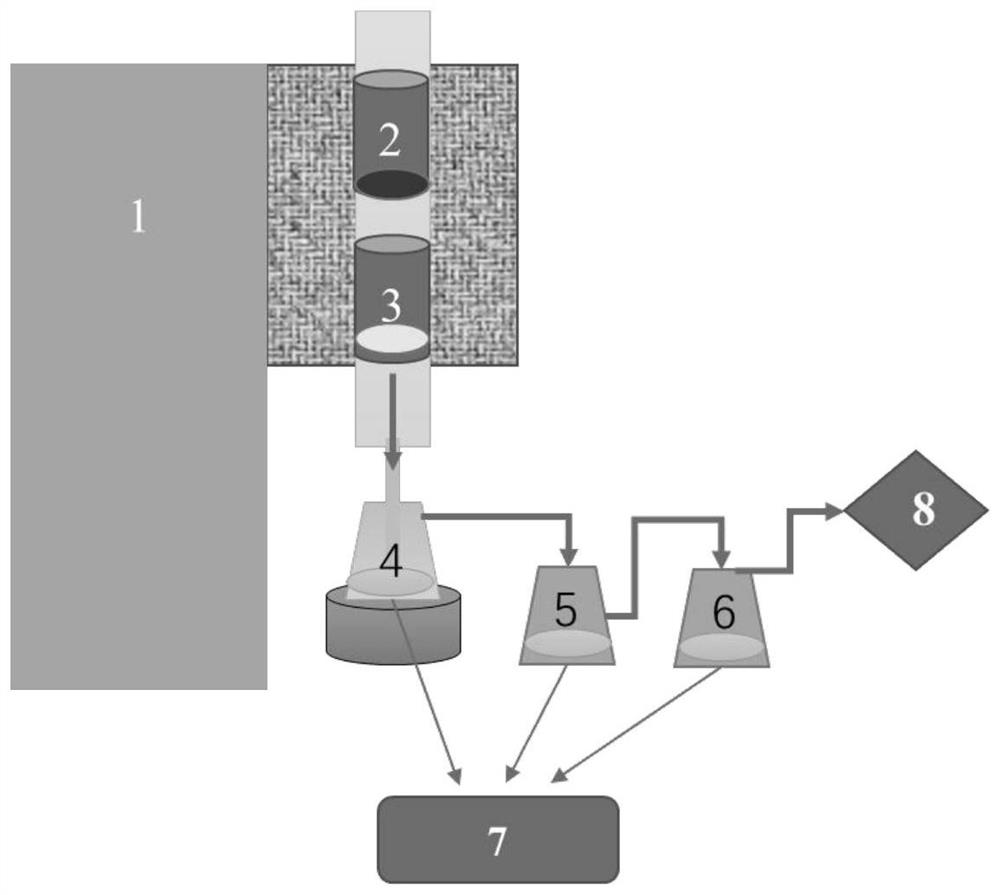

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a method for preparing hydrogen-rich gas by using aluminum smelting waste slag to catalyze biomass tar cracking, including:

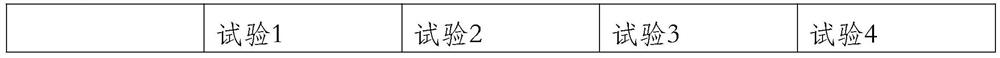

[0032] (1) Adding 0.5mol / L sulfuric acid to soak aluminum smelting waste slag for 2 hours, filter, and bake the obtained precipitate at 350°C for 4 hours to obtain pretreated aluminum smelting waste slag;

[0033] (2) Add the pretreated aluminum smelting waste slag to 1mol / L acetic acid, ultrasonically treat (ultrasonic frequency 20kHz, ultrasonic power 600W, processing time 30min), centrifuge the solution (2000r / min), and bake at a constant temperature of 450°C in an air atmosphere 4h, naturally cooled to room temperature to obtain a cracking catalyst;

[0034] (3) After mixing the cracking catalyst and biomass (crushed poplar to 200 mesh) in a mass ratio of 1:1, add to 90ml / min N 2 The primary pyrolysis furnace under the atmosphere is heated from room temperature to 900°C at a heating rate of 20°C / min to obtain the pri...

Embodiment 2

[0038] This embodiment provides a method for preparing hydrogen-rich gas by using aluminum smelting waste slag to catalyze biomass tar cracking, including:

[0039] (1) Add 1 mol / L nitric acid to soak aluminum smelting waste residue for 2 hours, filter, and bake the obtained precipitate at 350° C. for 4 hours to obtain pretreated aluminum smelting waste residue;

[0040] (2) Add the pretreated aluminum smelting waste slag to 1mol / L acetic acid, ultrasonically treat (ultrasonic frequency 20kHz, ultrasonic power 600W, processing time 30min), centrifuge the solution (2000r / min), and bake at a constant temperature of 450°C in an air atmosphere 4h, naturally cooled to room temperature to obtain a cracking catalyst;

[0041] (3) After mixing the cracking catalyst and biomass (crushed poplar to 200 mesh) in a mass ratio of 1:1, add to 90ml / min N 2 The primary pyrolysis furnace under the atmosphere is heated from room temperature to 900°C at a heating rate of 20°C / min to obtain the p...

Embodiment 3

[0044] This embodiment provides a method for preparing hydrogen-rich gas by using aluminum smelting waste slag to catalyze biomass tar cracking, including:

[0045] (1) Add 0.5mol / L phosphoric acid to soak aluminum smelting waste residue for 2 hours, filter, and bake the resulting precipitate at 350°C for 4 hours to obtain pretreated aluminum smelting waste residue;

[0046] (2) Add the pretreated aluminum smelting waste slag to 1mol / L acetic acid, ultrasonically treat (ultrasonic frequency 20kHz, ultrasonic power 600W, processing time 30min), centrifuge the solution (2000r / min), and bake at a constant temperature of 450°C in an air atmosphere 4h, naturally cooled to room temperature to obtain a cracking catalyst;

[0047] (3) After mixing the cracking catalyst and biomass (crushed poplar to 200 mesh) in a mass ratio of 1:1, add to 90ml / min N 2 The primary pyrolysis furnace under the atmosphere is heated from room temperature to 900°C at a heating rate of 20°C / min to obtain the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com