Photoelectrode material based on InGaN/organic heterostructure and preparation method and application thereof

A technology of heterostructures and organic materials, applied in the field of InGaN nanopillars, can solve problems such as slow oxidation reaction kinetics, and achieve the effects of promoting separation and transport properties, improving optoelectronic properties, and promoting production and transport.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

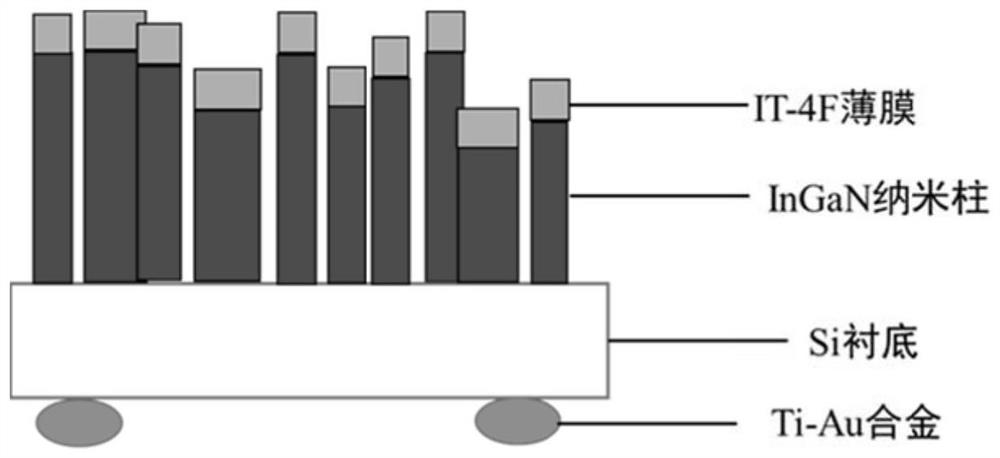

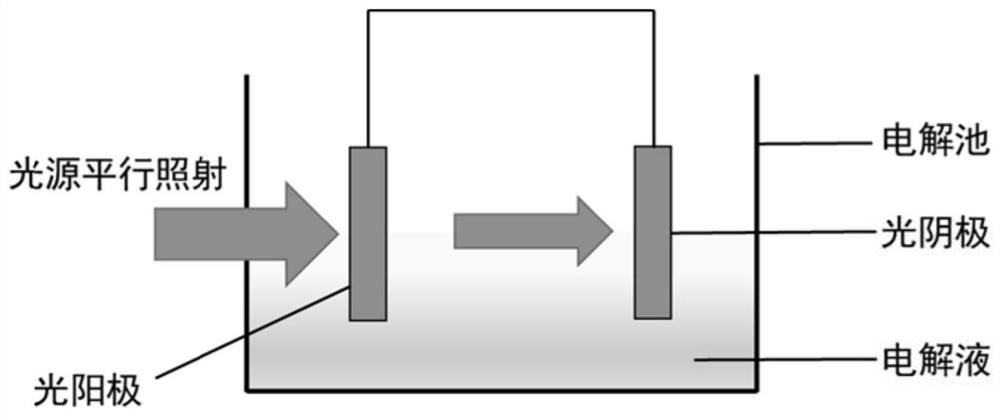

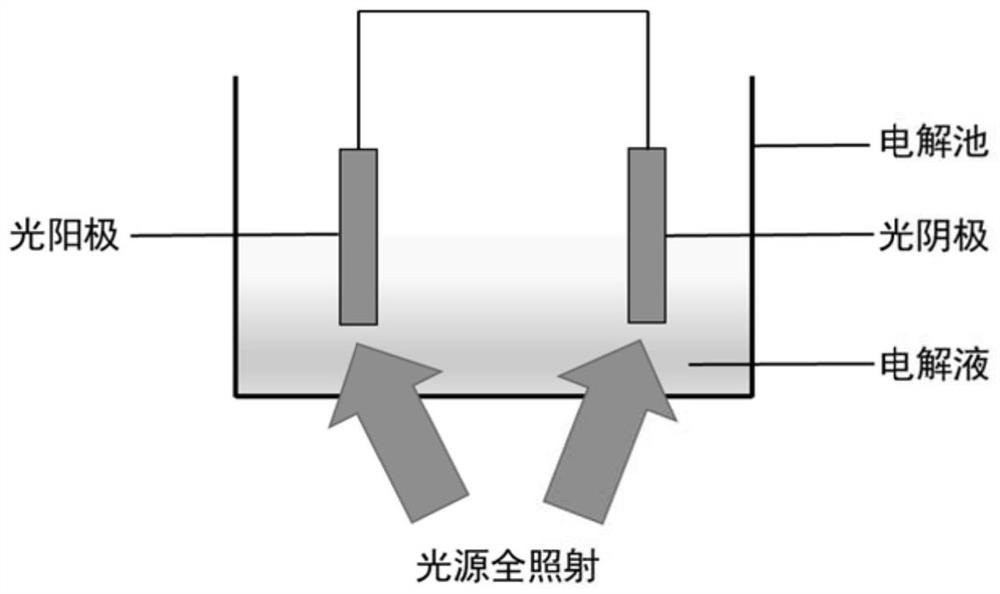

[0034] The construction and application of a photoelectrochemical hydrogen production system based on InGaN / organic heterostructure photoelectrode material without bias voltage, comprising the following steps:

[0035] (1) Selection of substrate: n-type Si is used as the substrate (conductivity < 0.005Ω).

[0036] (2) Photocathode preparation: Then, the molecular beam epitaxy growth process was adopted, the substrate temperature was controlled to be 900 °C, the substrate rotation speed was 10 r / min, and the equivalent pressure of the Ga beam was 1×10 -7 Torr, In beam equivalent pressure is 2.0×10 -7 Torr, the nitrogen flow rate is 2sccm, the plasma source power is 400W, and the growth time is 3h. InGaN nanopillars are grown on the Si substrate. Among them, InGaN nanopillars account for 20% of In atoms, and the height of the nanopillars is 100-400nm. The diameter is 60~90nm, the density is 100~300μm -2 . The organic material IT-4F was deposited on the InGaN nanopillars, and ...

Embodiment 2

[0041] The construction and application of a photoelectrochemical hydrogen production system based on InGaN / organic heterostructure photoelectrode material without bias voltage, comprising the following steps:

[0042] (1) Selection of substrate: n-type Si is used as the substrate (conductivity < 0.005Ω).

[0043] (2) Photocathode preparation: Then, the molecular beam epitaxy growth process was adopted, the substrate temperature was controlled to be 900 °C, the substrate rotation speed was 10 r / min, and the equivalent pressure of the Ga beam was 1×10 -7 Torr, In beam equivalent pressure is 2.0×10 -7 Torr, the nitrogen flow rate is 2sccm, the plasma source power is 400W, and the growth time is 3h. InGaN nanopillars are grown on the Si substrate. Among them, InGaN nanopillars account for 20% of In atoms, and the height of the nanopillars is 100-400nm. The diameter is 60~90nm, the density is 100~300m -2 . The organic material IT-4F was deposited on the InGaN nanopillars, and t...

Embodiment 3

[0048] The construction and application of a photoelectrochemical hydrogen production system based on InGaN / organic heterostructure photoelectrode material without bias voltage, comprising the following steps:

[0049] (1) Selection of substrate: n-type Si is used as the substrate (conductivity < 0.005Ω).

[0050] (2) Photocathode preparation: Then, the molecular beam epitaxy growth process was adopted, the substrate temperature was controlled to be 900 °C, the substrate rotation speed was 10 r / min, and the equivalent pressure of the Ga beam was 1×10 -7 Torr, In beam equivalent pressure is 2.0×10 -7 Torr, the nitrogen flow rate is 2sccm, the plasma source power is 400W, and the growth time is 3h. InGaN nanopillars are grown on the Si substrate. Among them, InGaN nanopillars account for 20% of In atoms, and the height of the nanopillars is 100-400nm. The diameter is 60~90nm, the density is 100~300m -2 . The organic material IT-4F was deposited on the InGaN nanopillars, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com