Composite diaphragm for semi-solid lithium battery and preparation method of composite diaphragm

A technology of composite diaphragm and lithium battery, which is applied in the direction of battery components, circuits, electrical components, etc., can solve the problem that the composite diaphragm of semi-solid lithium battery cannot meet the requirements, the ion conductivity is difficult to meet the actual needs, and the ion conductivity is not enough. Satisfactory and other issues, to achieve the effect of enhancing the migration number of lithium ions, avoiding leakage, combustion and explosion, strong liquid absorption capacity and liquid retention capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

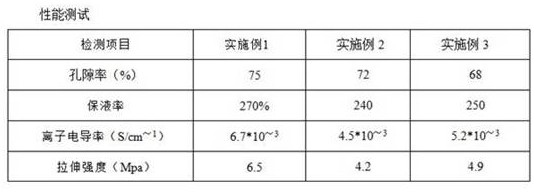

Examples

Embodiment 1

[0029] Step 1: Preparation of polyvinyl alcohol-coated ceramic nanowire slurry:

[0030] Take the first polyvinyl alcohol (98% ~ 100%, 200,000 molecular weight) 5g, 75g deionized water to dissolve completely, transfer to a vacuum reactor, then add 20g aluminum chloride, 1g sodium hydroxide, 2g hexadecyl Trimethylammonium bromide, and reacted in an oil bath at 150°C for 24h, then cooled, centrifuged, washed and precipitated until high-concentration polyvinyl alcohol-coated ceramic nano-slurry; then take 30g of polyvinyl alcohol-coated ceramic nano-slurry, the second 3g of polyvinyl alcohol (98%-100%, molecular weight of 120,000) and 67g of deionized water were mixed and stirred in a vacuum reactor at 80°C for 30 minutes to prepare nano-slurry A for later use.

[0031] Step 2: Preparation of semi-solid lithium battery base film:

[0032] Take 4g of PMMA powder, 16g of PVDF powder, 70g of NMP, and 10g of acetone into a vacuum reactor, then move to a 120°C oil bath and stir for 2...

Embodiment 2

[0036] Step 1: Preparation of polyvinyl alcohol-coated ceramic nanowire slurry:

[0037] Take the first polyvinyl alcohol (98% ~ 100%, 200,000 molecular weight) 5g, 70g deionized water to dissolve completely, transfer to a vacuum reactor, then add 25g aluminum chloride, 1.5g sodium hydroxide, 3g hexadecane Trimethylammonium bromide, and reacted in an oil bath at 180°C for 20h, then cooled, centrifuged, washed and precipitated until the high-concentration polyvinyl alcohol-coated ceramic nano-slurry; then take 25g of polyvinyl alcohol-coated ceramic nano-slurry, the first Divinyl alcohol (98%-100%, 120,000 molecular weight) 3g and 67g deionized water were mixed and stirred in a vacuum reactor at 60°C for 1 hour to make nano slurry A for later use.

[0038] Step 2: Preparation of semi-solid lithium battery base film:

[0039] Take 6g of PMMA powder, 18g of PVDF powder, 66g of NMP, and 10g of acetone into a vacuum reactor, then move to a 120°C oil bath and stir for 2 hours to di...

Embodiment 3

[0043] Step 1: Preparation of polyvinyl alcohol-coated ceramic nanowire slurry:

[0044] Take the first polyvinyl alcohol (98% ~ 100%, 200,000 molecular weight) 5g, 80g deionized water to dissolve completely, transfer to a vacuum reactor, then add 15g aluminum chloride, 1g sodium hydroxide, 2g hexadecyl Trimethylammonium bromide, and reacted in 200 ℃ oil bath for 12h, then cooled, centrifuged, washed and precipitated until high-concentration polyvinyl alcohol-coated ceramic nano-slurry; then took 35g of polyvinyl alcohol-coated ceramic nano-slurry, and 3 g of polyvinyl alcohol (98%-100%, 120,000 molecular weight) and 62 g of deionized water were mixed and stirred in a vacuum reactor at 80°C for 30 minutes to prepare nano-slurry A for later use.

[0045] Step 2: Preparation of semi-solid lithium battery base film:

[0046] Take 8g of PMMA powder, 16g of PVDF powder, 66g of NMP, and 10g of acetone into a vacuum reactor, then move it to an oil bath at 120°C and stir for 2 hours to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com