Microbial filler attached with halotolerant bacteria as well as preparation method and application of microbial filler

A technology of microorganisms and salt-tolerant bacteria, applied in the methods of using microorganisms, biochemical equipment and methods, chemical instruments and methods, etc., can solve problems such as unstable operation, and achieve a wide range of applications, strong impact resistance, and stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

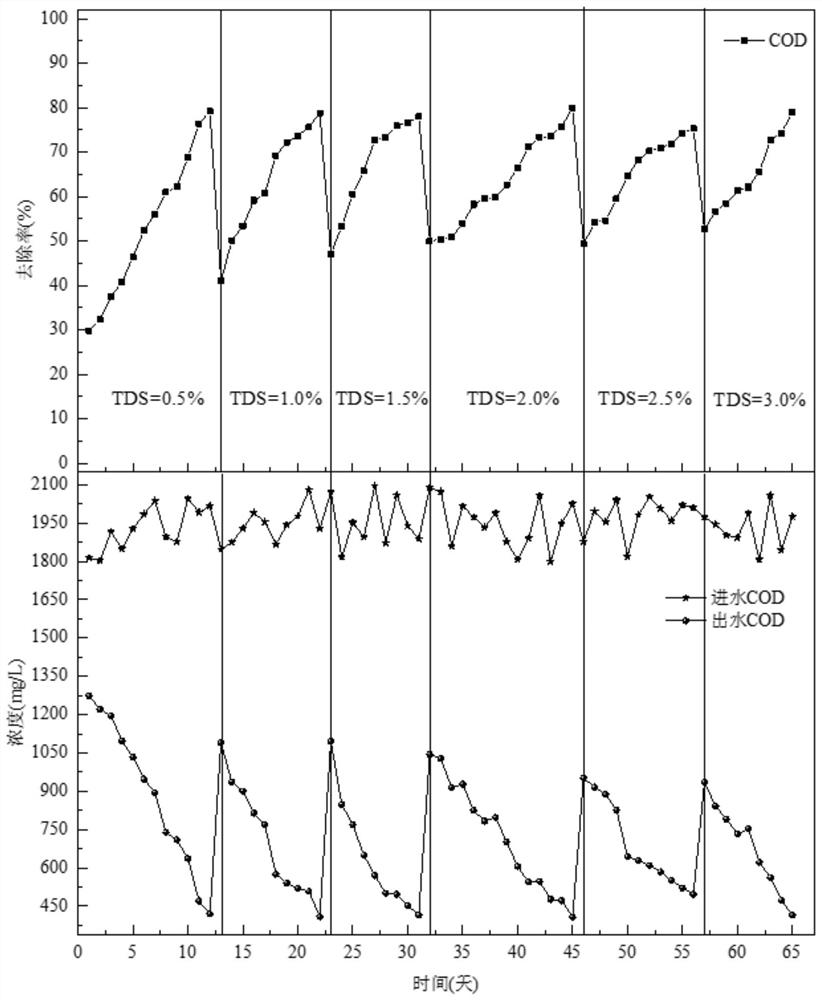

[0026] The invention provides a method for preparing microbial fillers attached with salt-tolerant bacteria, which includes a domestication step. In the domestication step, the microbial fillers that have been filmed are used as domestication objects, and the concentration of the original salt-tolerant bacteria on the microbial fillers is greater than 0%. The original MLSS on the microbial filler is ≥ 5000mg / L, and the saline with increasing salt concentration is used for domestication, and high-efficiency salt-tolerant bacteria are added during the domestication process until the microbial filler has no effect on the water body in the saline with a salt concentration of 3.0wt%. The removal rate of COD reached above 75%, and the MLSS on the microbial filler was ≥ 5000mg / L, and the target product was obtained; the salt concentration range of the brine was 0-3.0wt%, and the salt concentration of the brine increased with C as a gradient , 0wt%<C<1.5wt%.

[0027] Among them, when ...

Embodiment 1

[0036] A preparation method of a microbial filler attached with salt-tolerant bacteria in this embodiment comprises the following steps:

[0037] S1. Preparatory steps: Prepare the microbial filler with film in advance, the concentration of the original salt-tolerant bacteria on the microbial filler is 5%, and the original MLSS on the microbial filler is ≥ 5000mg / L. The microbial filler includes a filler skeleton, which is made of nylon fiber. The filler skeleton made of nylon fiber has the characteristics of high strength, strong toughness, and long life, and can provide a large number of attachment sites for salt-tolerant bacteria. convenient.

[0038] S2, domestication step: take the microbial filler in step S1 as the domestication object, adopt the saline solution with increasing salt concentration gradient for domestication, and add high-efficiency salt-tolerant bacteria in the domestication process until the saline solution with a salt concentration of 3.0wt% Among them...

Embodiment 2

[0045] The only difference between this example and Example 1 is that in this example, in "S2, acclimation step", the ratio of the dosage of high-efficiency salt-tolerant bacteria solution to the water inflow is 0.3mL / L.

[0046] In this example, the time to obtain the target product (microbial filler with salt-tolerant bacteria attached) was 62 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com