Nanogold-containing polyvinyl pyrrolidone/poly (N-vinylcaprolactam) hybrid microgel and preparation method thereof

A technology of polyvinylpyrrolidone and vinylcaprolactam, applied in the direction of nanotechnology, nanotechnology, metal processing equipment, etc., can solve the problem of limiting the selection of functional components, and achieve the effect of multi-selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

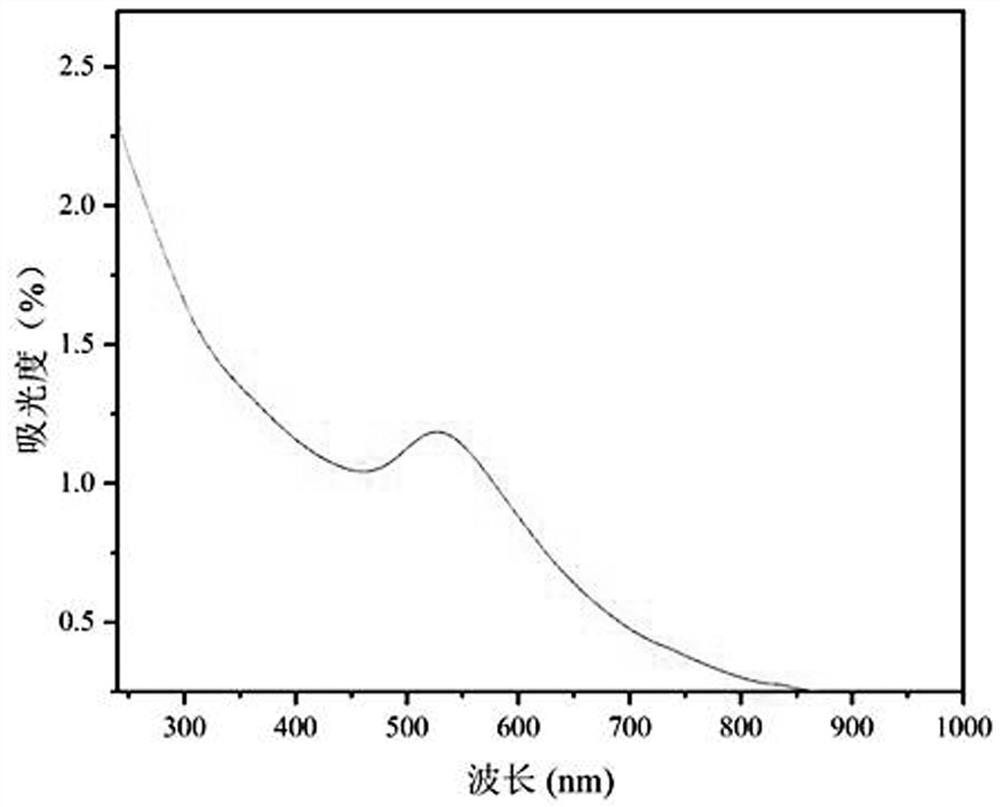

Image

Examples

preparation example Construction

[0027] A preparation method of polyvinylpyrrolidone / polyN-vinylcaprolactam hybrid microgel containing nano-gold, comprising the steps of:

[0028] Step 1. Preparation of self-reducing polyvinylpyrrolidone / poly(N-vinylcaprolactam) composite microgel.

[0029] Take 100-300 parts of secondary distilled water, pour it into a three-necked flask, take vinylpyrrolidone, ethylene glycol dimethacrylate, azobisisobutylamidine hydrochloride, dissolve it in distilled water and pour it into the bottle , turn on the overhead stirrer to stir; pass through the nitrogen to fully exhaust the oxygen, and then put the reaction device into a constant temperature water bath for about 3-7 hours to react to obtain polyvinylpyrrolidone latex; take 200 parts of twice distilled water and 10-20 parts Pour polyvinylpyrrolidone latex into a three-necked flask; take the initiator persulfate or the mixed solution of tetramethylethylenediamine and ammonium persulfate, N-vinylcaprolactam, N,N'-methylene base ...

Embodiment 1

[0039]Put 3 parts of vinylpyrrolidone, 0.9 parts of ethylene glycol dimethacrylate, 0.25 parts of azobisisobutylamidine hydrochloride and 300 parts of distilled water into a three-necked flask, stir with a stirrer at 300 rpm / min; feed nitrogen into the system 15ml / min, to fully remove the oxygen in the system; place the bottle in constant temperature water at 60°C for 6 hours of reaction. The reaction process is protected by nitrogen. After the reaction, polyvinylpyrrolidone latex is obtained; 10 parts of polyvinylpyrrolidone latex and 200 parts of twice distilled water are poured into a three-necked flask; 5 parts of N-vinylcaprolactam, 0.2 parts of persulfuric acid Potassium, 1 part of N,N'-methylenebisacrylamide, dissolved in distilled water and poured into the bottle; stirrer at 300rpm / min, after removing the oxygen in the system, put the bottle into 70°C constant temperature water, and react 6 Hours, polyvinylpyrrolidone / poly(N-vinylcaprolactam) microgels were obtained. ...

Embodiment 2

[0042] Put 6 parts of vinylpyrrolidone, 0.8 parts of ethylene glycol dimethacrylate, 0.25 parts of azobisisobutylamidine hydrochloride and 300 parts of distilled water into a three-necked flask, stir with a stirrer at 200 rpm / min; feed nitrogen into the system 17ml / min to fully remove the oxygen in the system; place the bottle in constant temperature water at 60°C for 6 hours of reaction. The reaction process is protected by nitrogen. After the reaction, after the obtained polyvinylpyrrolidone latex is purified, 10 parts of polyvinylpyrrolidone latex and 200 parts of twice distilled water are poured into a three-necked flask; 8 parts of N-vinylcaprolactam, 0.34 1 part of potassium persulfate, 1.6 parts of N,N'-methylenebisacrylamide, dissolved in distilled water and poured into the bottle; stirrer at 200rpm / min, remove the oxygen in the system and put the bottle into 70℃ constant temperature water, React for 6 hours to obtain polyvinylpyrrolidone / poly(N-vinylcaprolactam) micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com