Liquid core hydrogel optical fiber, preparation method and application of liquid core hydrogel optical fiber, liquid core hydrogel optical fiber probe sensor and application of liquid core hydrogel optical fiber probe sensor

A technology of fiber optic probe and hydrogel, which is applied in the field of fiber optics, can solve the problems of insufficient combination of sensing materials and measured objects, difficulty in reusing fiber optic probes, and difficulty in elution of sensing materials, etc., to achieve reusability High efficiency, wide application range, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The raw materials for the preparation of the hollow hydrogel core include the first hydrogel monomer, photoinitiator and water;

[0042] The raw materials for the preparation of the hydrogel coating include a second hydrogel monomer, calcium chloride and water; the refractive index of the second hydrogel monomer is smaller than that of the first hydrogel monomer;

[0043] The liquid core includes a light transmitting liquid core or a sensing liquid core.

[0044] In the present invention, the first hydrogel monomer preferably includes one or more of polyethylene glycol diacrylate, alginic acid, polymethylmethacrylate, polyvinyl alcohol and polylactic acid-glycolic acid copolymer. kind. In the present invention, the photoinitiator preferably includes 2-hydroxyl-2-methyl-1-phenyl-1-propanone and / or 2-hydroxyl-4-(2-hydroxyethoxy)-2-methanone Propiophenone. In the present invention, the inner diameter of the hollow hydrogel core is 0.5 to 1 mm, more preferably 0.6 to 0.9...

Embodiment 1

[0081] Mix 1081.2 μL of polyethylene glycol diacrylate, 55.7 μL of 2-hydroxy-2-methyl-1-phenyl-1-acetone photoinitiator and 1863.1 μL of deionized water, and degas it through an ultrasonic cleaner for 20 minutes to obtain 3 mL of hydrogel precursor solution.

[0082] Put a hollow silicone tube with an inner diameter of 0.50 mm into a hollow silicone tube with an inner diameter of 2 mm to obtain a coaxial sleeve, inject the hydrogel precursor solution into the annular area of the coaxial sleeve with a syringe and place it at 365 ~405nm UV light source for 5min, push out the coaxial hollow silica gel sleeve with deionized water, and get the hollow hydrogel core;

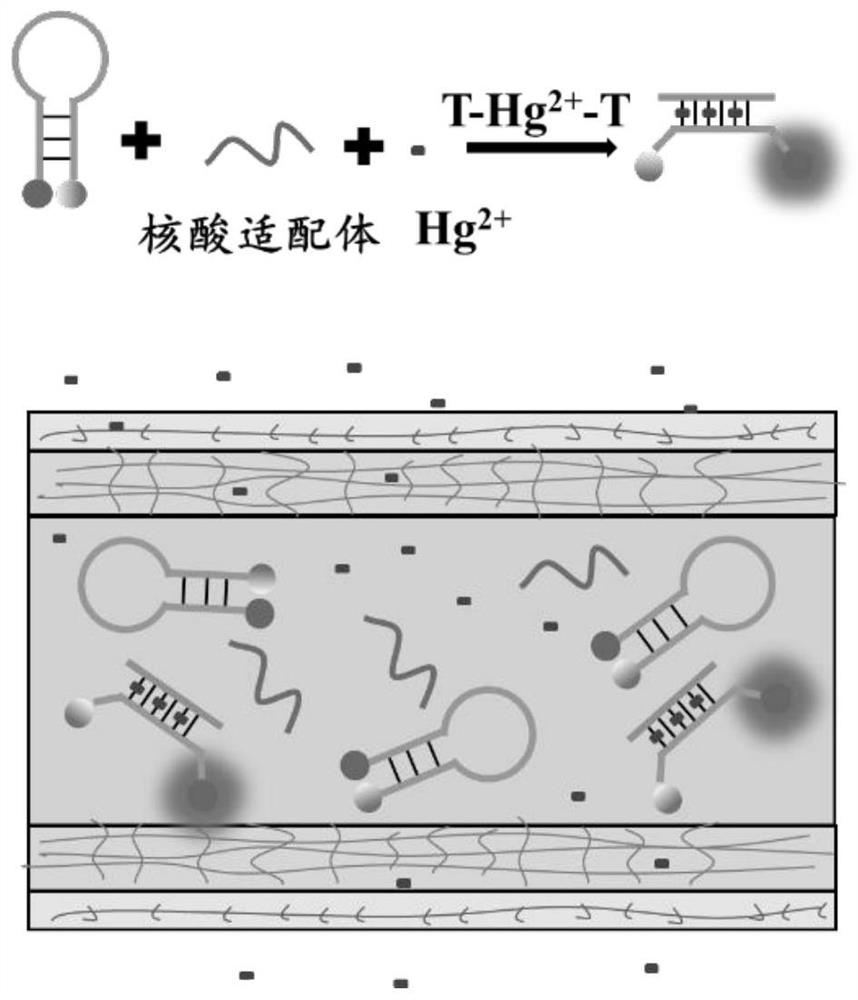

[0083] Inject the aqueous solution of molecular beacon and nucleic acid aptamer (the concentration of molecular beacon is 1 μ mol / L; The concentration of nucleic acid aptamer is 1 μ mol / L) in described hollow hydrogel fiber core, carry out with UV glue at both ends. Closed to obtain the liquid core hydrogel core.

...

Embodiment 2

[0087] Mix 1081.2 μL of polyethylene glycol diacrylate, 55.7 μL of 2-hydroxy-2-methyl-1-phenyl-1-acetone photoinitiator and 1863.1 μL of deionized water, and degas it through an ultrasonic cleaner for 20 minutes to obtain 3 mL of hydrogel precursor solution.

[0088] Put a hollow silicone tube with an inner diameter of 0.50 mm into a hollow silicone tube with an inner diameter of 2 mm to obtain a coaxial sleeve, inject the hydrogel precursor solution into the annular area of the coaxial sleeve with a syringe and place it at 365 ~405nm UV light source for 5min, push out the coaxial hollow silica gel sleeve with deionized water, and get the hollow hydrogel core;

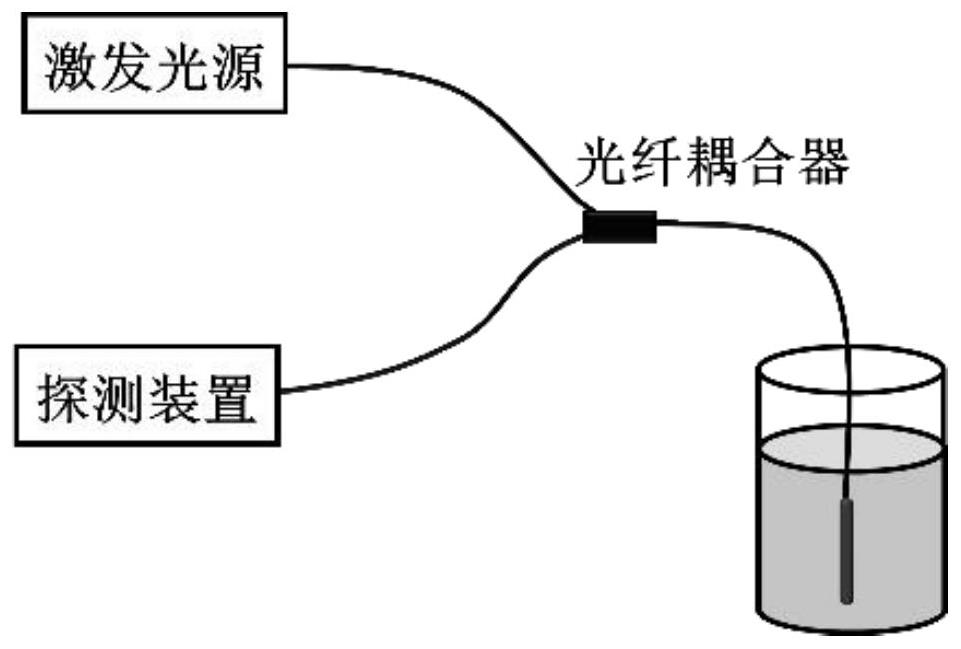

[0089] CdSe / ZnS QDs aqueous solution (particle diameter is 10~12nm, concentration is 1 μ mol / L) in described hollow hydrogel fiber core, inserts the quartz optical fiber that core diameter is 105 μ m then at one end, seals and seals with UV glue The silica optical fiber was fixed, and the other end was sealed with U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com