Method for detecting boron in steel

A technology for the content of steel scraps and boron, which is applied in the preparation of test samples, thermal excitation analysis, material excitation analysis, etc. The effect of shortening inspection time, less environmental pollution and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

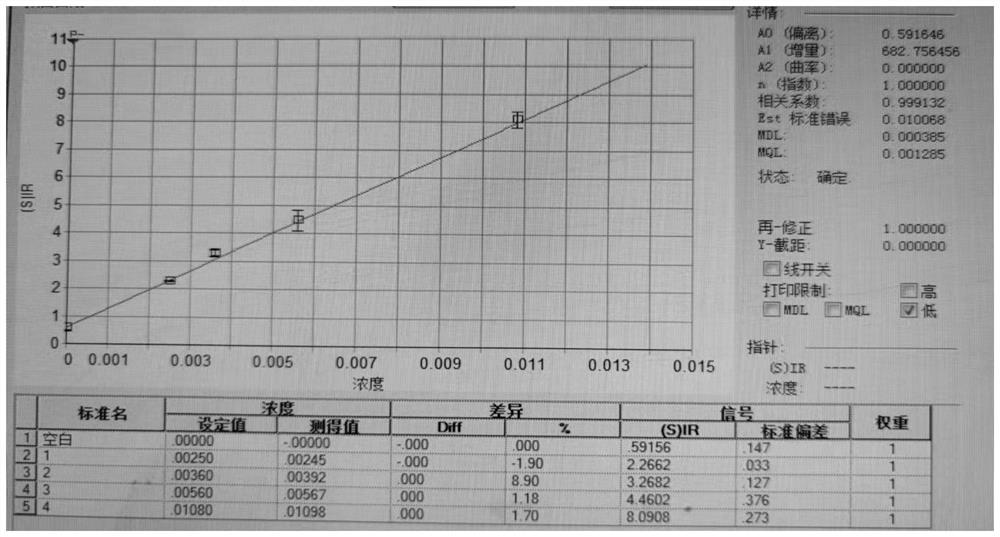

[0049] The national standard samples of medium and low alloy steel, low alloy steel and microalloy steel are respectively selected to test the accuracy and precision of the method of the present invention.

[0050] Sample dissolution: Weigh 0.2000g sample into a 200mL quartz beaker (accurate to 0.0001g), add 30mL sulfuric acid solution (1+6), heat and dissolve the sample at low temperature until the sample is completely dissolved. Remove the beaker, wait for the solution to cool slightly, add a small amount of water to boil to dissolve the salt, the solution should be clear and free of impurities, cool to room temperature (if the sample contains high carbon content, filter operation is required), and set the volume in a 100mL volumetric flask, Dilute to the mark with distilled water.

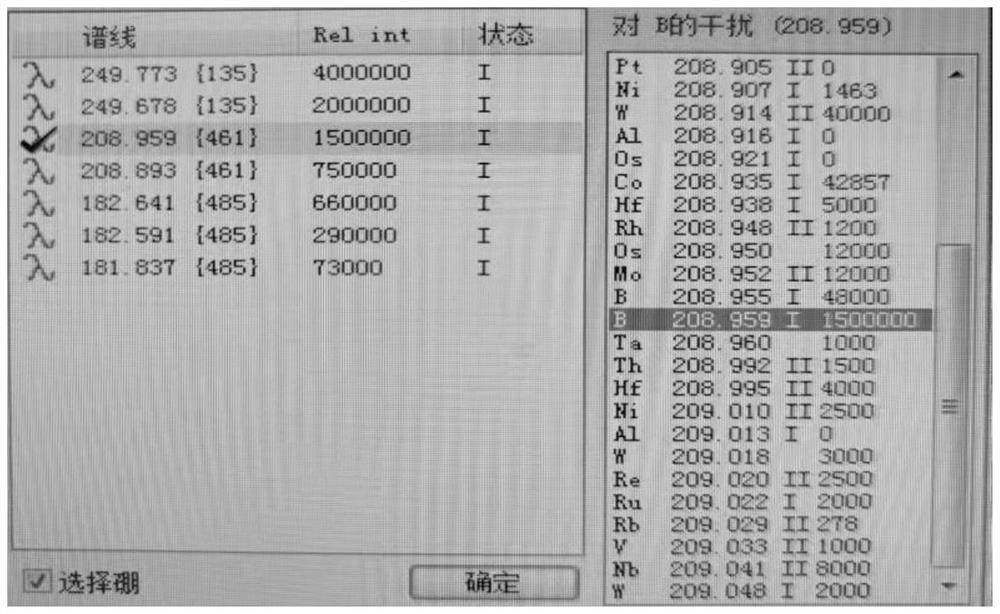

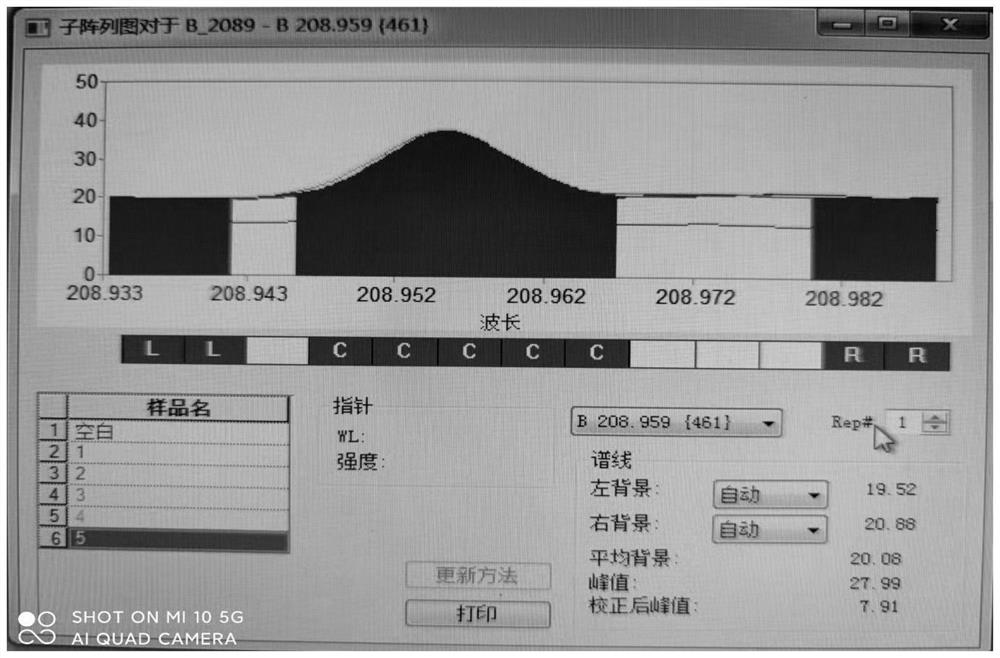

[0051] Working curve: Weigh steel standard samples with different boron contents into 200mL quartz beakers respectively, operate according to the above sample processing steps, and transfer the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com