ZnOxSy photocatalyst with high visible light hydrogen production activity and preparation method thereof

A photocatalyst and visible light technology, applied in chemical instruments and methods, physical/chemical process catalysts, hydrogen production, etc., can solve the problem of low visible light activity, achieve good visible light absorption, improve reaction efficiency and stability, and photogenerate electrons -Effect of fast hole transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

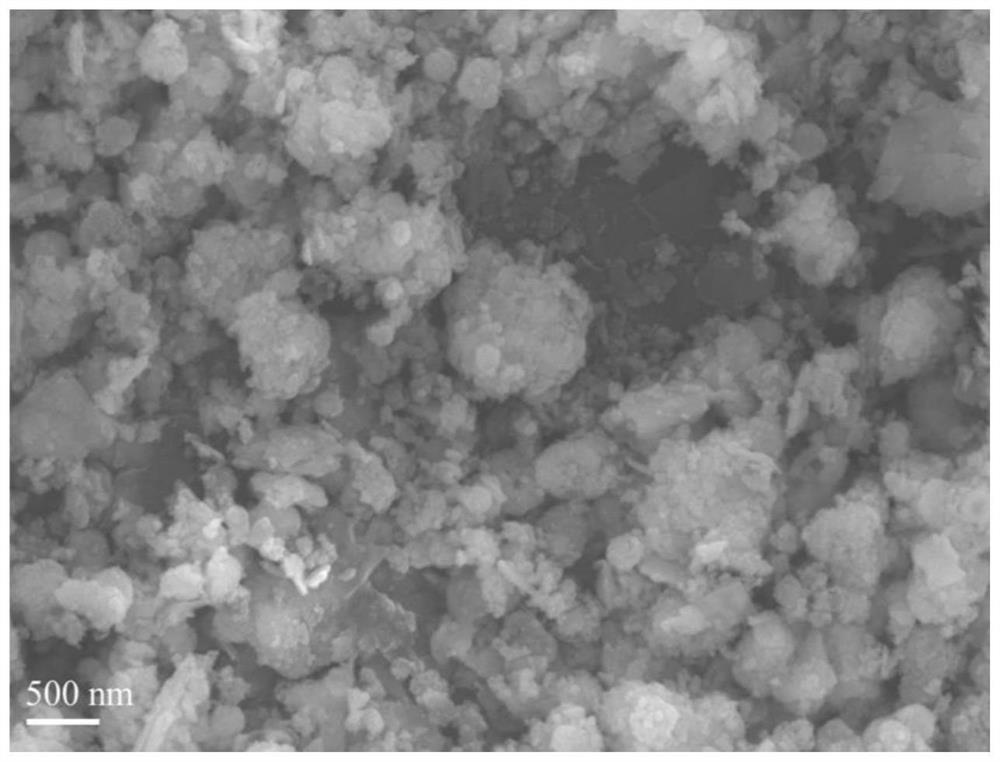

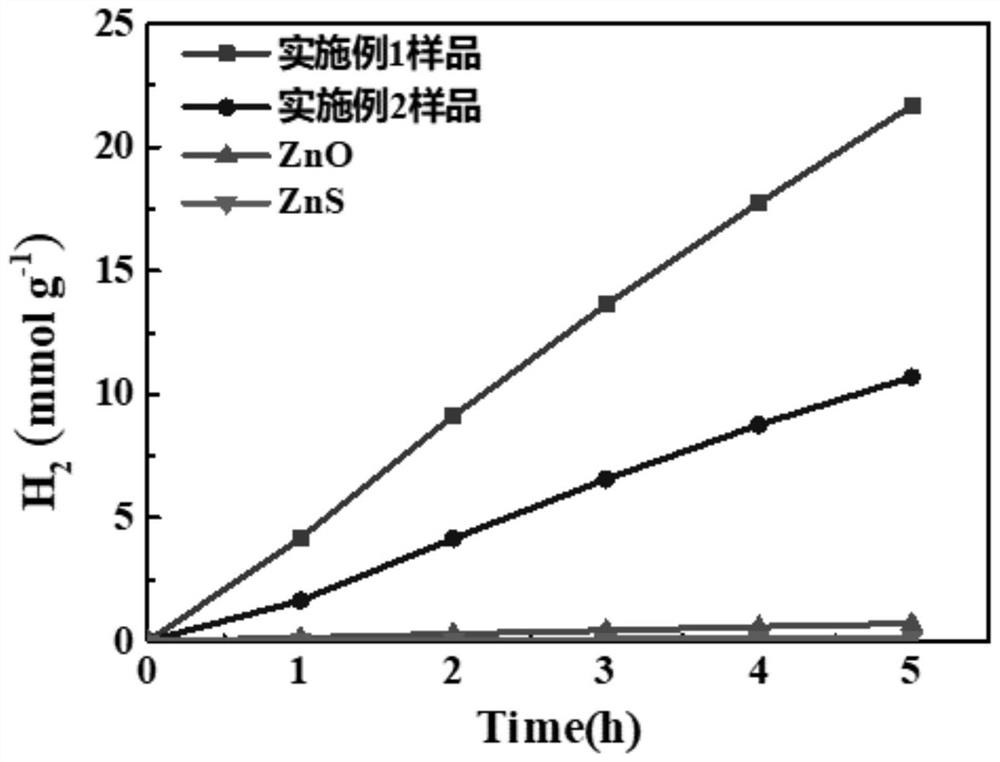

[0026] Dissolve 1mmol of zincite (0.549g) and 4mmol of thiourea in 30mL of deionized water, and ultrasonically disperse for 30 minutes; then transfer the mixture to 100mL of polytetrafluoroethylene lining, and place the polytetrafluoroethylene lining Put it into a stainless steel hydrothermal kettle, and place the hydrothermal kettle in an oven at 160°C to react for 24 hours; after the reaction, it is naturally cooled to room temperature, and the product is separated by filtration, and mixed with ethanol and deionized water with a volume ratio of 1:1 The solution was washed 3 times, and the solid product was dried in an oven at 60°C for 12 hours to obtain a composite catalyst precursor; then the composite catalyst precursor was placed in a tube furnace, and the temperature was raised at a heating rate of 2°C / min to Heat treatment at 400° C. for 2 h; after the reaction, cool to room temperature under nitrogen protection to obtain the ZnOxSy photocatalyst.

Embodiment 2

[0028] Dissolve 1mmol of zincite (0.549g) and 6mmol of thiourea in 30mL of deionized water, and ultrasonically disperse for 30 minutes; then transfer the mixture to 100mL of polytetrafluoroethylene lining, and place the polytetrafluoroethylene lining Put it into a stainless steel hydrothermal kettle, and place the hydrothermal kettle in an oven at 160°C to react for 24 hours; after the reaction, it is naturally cooled to room temperature, and the product is separated by filtration, and mixed with ethanol and deionized water with a volume ratio of 1:1 The solution was washed 3 times, and the solid product was dried in an oven at 60°C for 24 hours to obtain a composite catalyst precursor; then the composite catalyst precursor was placed in a tube furnace, and the temperature was raised at a heating rate of 5°C / min to Heat treatment at 400° C. for 2 h; after the reaction, cool to room temperature under nitrogen protection to obtain the ZnOxSy photocatalyst.

Embodiment 3

[0030] Dissolve 1mmol of zincite (0.549g) and 5mmol of thiourea in 30mL of deionized water, and ultrasonically disperse for 30 minutes; then transfer the mixture to 100mL of polytetrafluoroethylene lining, and place the polytetrafluoroethylene lining Put it into a stainless steel hydrothermal kettle, and place the hydrothermal kettle in an oven at 140°C to react for 48 hours; after the reaction, it is naturally cooled to room temperature, and the product is separated by filtration, and mixed with ethanol and deionized water with a volume ratio of 1:1 The solution was washed 3 times, and the solid product was dried in an oven at 60°C for 36 hours to obtain a composite catalyst precursor; then the composite catalyst precursor was placed in a tube furnace, and the temperature was raised to 10°C / min under the protection of nitrogen to Heat treatment at 450° C. for 2 hours; after the reaction, cool to room temperature under nitrogen protection to obtain the ZnOxSy photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com