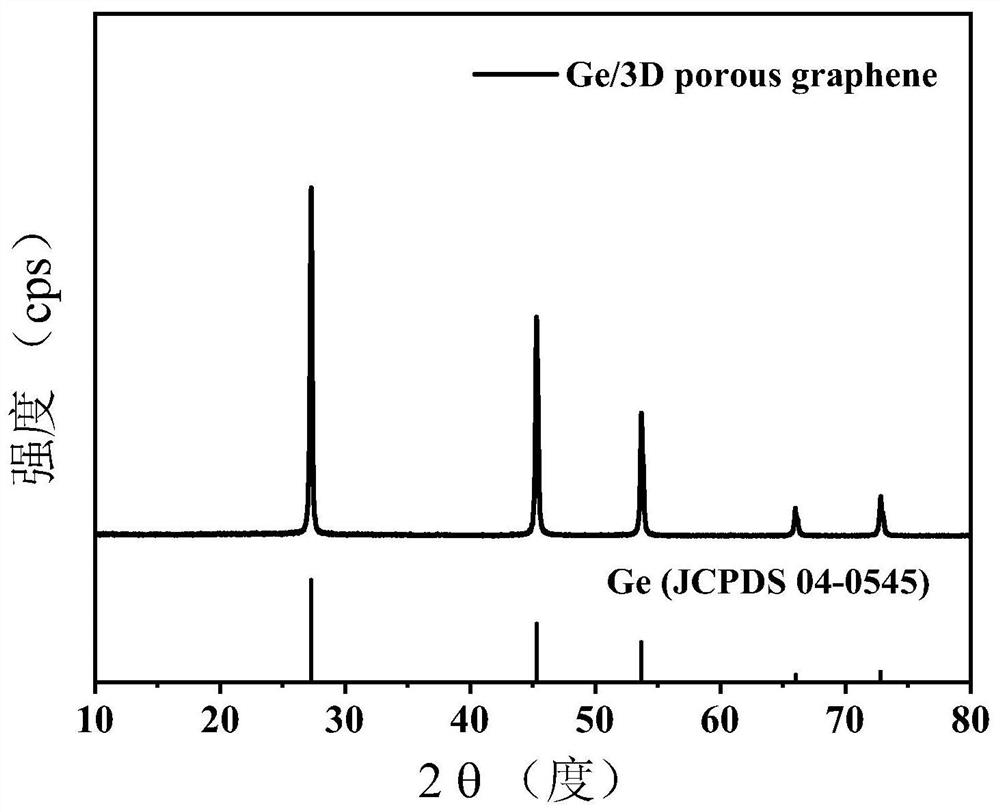

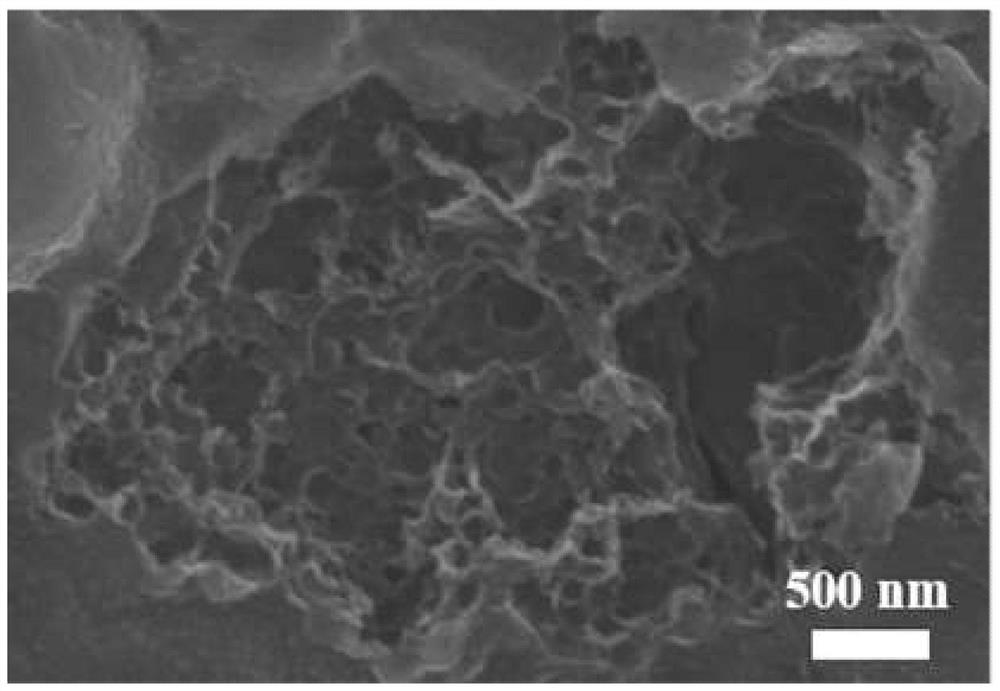

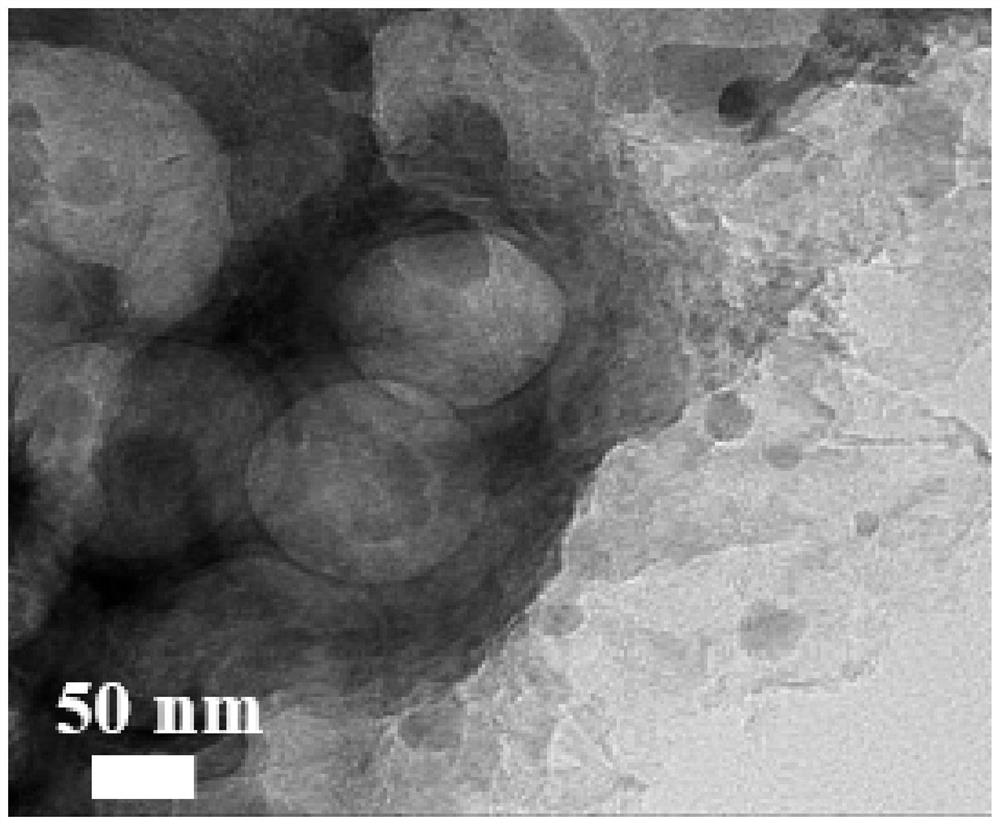

Preparation method of nano germanium/three-dimensional porous graphene composite material and application of nano germanium/three-dimensional porous graphene composite material to negative electrode of lithium ion battery

A three-dimensional porous, composite material technology, applied in graphene, battery electrodes, non-aqueous electrolyte battery electrodes, etc., can solve problems such as the volume change of germanium, and achieve the effects of low cost, excellent lithium storage performance, and simple and easy operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of nano-germanium / three-dimensional porous graphene composite material, comprising the steps of:

[0033] 60 mg of graphite oxide was ultrasonically dispersed in 30 ml of deionized water, and ultrasonically dispersed for 2 hours to obtain a graphene oxide dispersion.

[0034] Prepare 0.05mol / L sodium chloride solution (containing sodium chloride 0.18g, deionized water 62ml), respectively mix 2.16g polydiallyldimethylammonium chloride (PDDA) and 0.36g tris(hydroxymethyl) Aminomethane hydrochloride was dissolved in sodium chloride solution, 0.18g polystyrene microspheres were added, ultrasonicated for 1h, stirred for 6h, the product was centrifuged, washed with deionized water, and freeze-dried (-50°C) to obtain PDDA Modified polystyrene microspheres.

[0035] Then 0.04 g of PDDA-modified polystyrene microspheres were ultrasonically dispersed in 40 ml of deionized water to obtain a PDDA-modified polystyrene microsphere dispersion.

[0036]Prepare a ...

Embodiment 2

[0044] A preparation method of nano-germanium / three-dimensional porous graphene composite material, comprising the steps of:

[0045] 60 mg of graphite oxide was ultrasonically dispersed in 30 ml of deionized water, and ultrasonically dispersed for 2 hours to obtain a graphene oxide dispersion.

[0046] Prepare 0.05mol / L sodium chloride solution (containing 0.18g of sodium chloride, 62ml of deionized water), respectively mix 2.16g of polydiallyldimethylammonium chloride (PDDA) and 0.36g of tris(hydroxymethyl) Aminomethane hydrochloride was dissolved in sodium chloride solution, 0.18g of polystyrene microspheres were added, ultrasonicated for 1h, stirred for 6h, the product was centrifuged, washed with deionized water, and freeze-dried (-50°C) to obtain PDDA Modified polystyrene microspheres.

[0047] Then 0.04 g of PDDA-modified polystyrene microspheres were ultrasonically dispersed in 40 ml of deionized water to obtain a PDDA-modified polystyrene microsphere dispersion.

[...

Embodiment 3

[0053] A preparation method of nano-germanium / three-dimensional porous graphene composite material, comprising the steps of:

[0054] 60 mg of graphite oxide was ultrasonically dispersed in 30 ml of deionized water, and ultrasonically dispersed for 2 hours to obtain a graphene oxide dispersion.

[0055] Prepare 0.05mol / L sodium chloride solution (containing 0.18g of sodium chloride, 62ml of deionized water), respectively mix 2.16g of polydiallyldimethylammonium chloride (PDDA) and 0.36g of tris(hydroxymethyl) Aminomethane hydrochloride was dissolved in sodium chloride solution, 0.18g of polystyrene microspheres were added, ultrasonicated for 1h, stirred for 6h, the product was centrifuged, washed with deionized water, and freeze-dried (-50°C) to obtain PDDA Modified polystyrene microspheres.

[0056] Then 0.04 g of PDDA-modified polystyrene microspheres were ultrasonically dispersed in 40 ml of deionized water to obtain a PDDA-modified polystyrene microsphere dispersion.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com