Gypsum-based lightweight plastering material and preparation method thereof

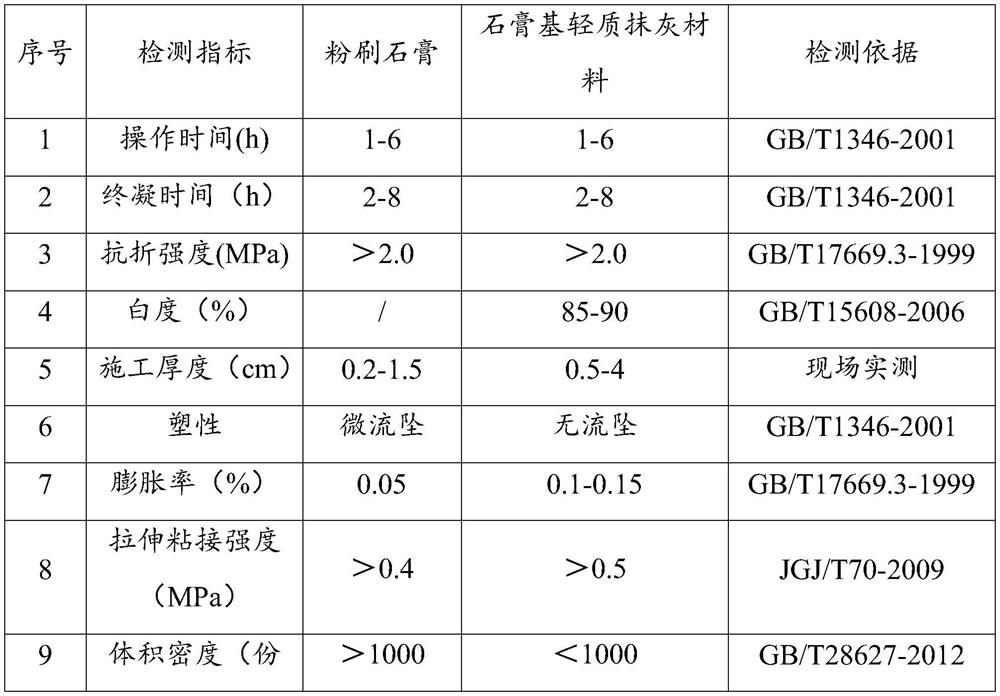

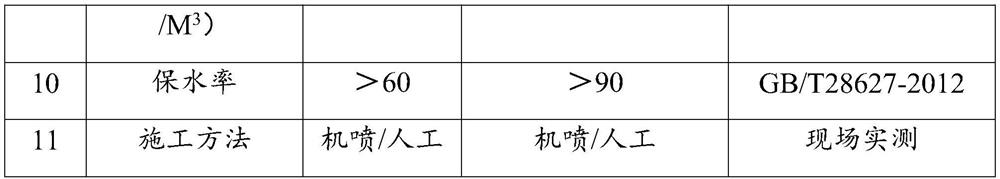

A gypsum-based, light-weight technology, applied in the field of housing construction, can solve the problems of inability to form one-time delivery, insufficient bonding strength, insufficient surface layer strength, etc., to save material costs and construction costs, whiteness and purity, and plastic effects excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A gypsum-based lightweight plastering material, comprising the following raw materials in parts by weight: 500 parts of natural white gypsum powder, 200 parts of heavy calcium powder, 300 parts of white sand, 1.5 parts of retarder (vegetable protein), thickener (hydroxypropyl methylcellulose) 2 parts, plasticizer (hydroxypropyl modified starch ether) 1 part, anti-cracking agent (ash calcium) 10 parts, air-entraining agent (sodium dodecylbenzene sulfonate) 0.3 2 parts, 2 parts of pigment (ultramarine blue).

Embodiment 2

[0041] A gypsum-based lightweight plastering material, comprising the following raw materials in parts by weight: 500 parts of natural white gypsum powder, 166 parts of heavy calcium powder, 334 parts of white sand, 1.5 parts of retarder (calcium gluconate), thickening 2.5 parts of agent (organic bentonite), 1.5 parts of plasticizer (modified polyvinyl alcohol), 8 parts of anti-cracking agent (light calcium), 0.3 parts of air-entraining agent (modified rosin), 2 parts of pigment (ultramarine blue).

Embodiment 3

[0043] A gypsum-based lightweight plastering material, comprising the following raw materials in parts by weight: 600 parts of natural white gypsum powder, 200 parts of heavy calcium powder, 200 parts of white sand, 2 parts of retarder (lactic acid salt), thickening 2 parts of agent (hydroxyethyl cellulose), 2 parts of plasticizer (grafted starch), 5 parts of anti-cracking agent (ash calcium), 0.1 part of air-entraining agent (C12 fatty alcohol polyvinyl chloride alkyl ether), pigment ( Titanium dioxide + ultramarine) 2.5 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com