Non-ionic surface active agent modified direct-writing type 3D printing general ink and preparation and printing method of non-ionic surface active agent modified direct-writing type 3D printing general ink

A non-ionic surface and 3D printing technology, applied in the field of 3D printing materials, can solve problems such as uneven structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

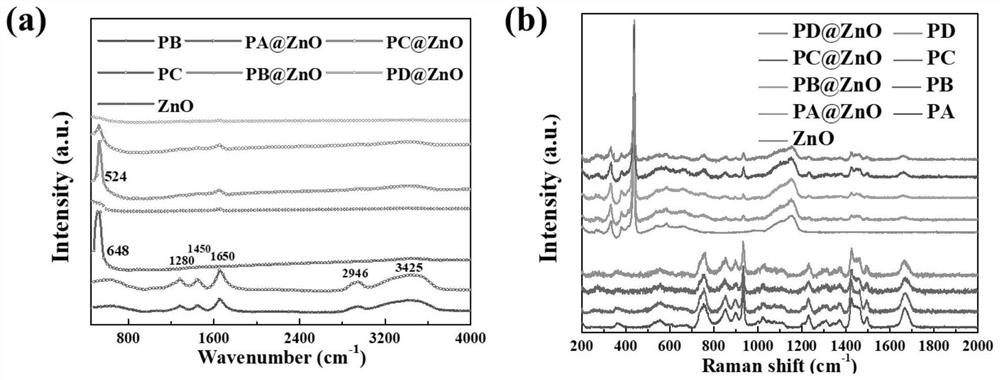

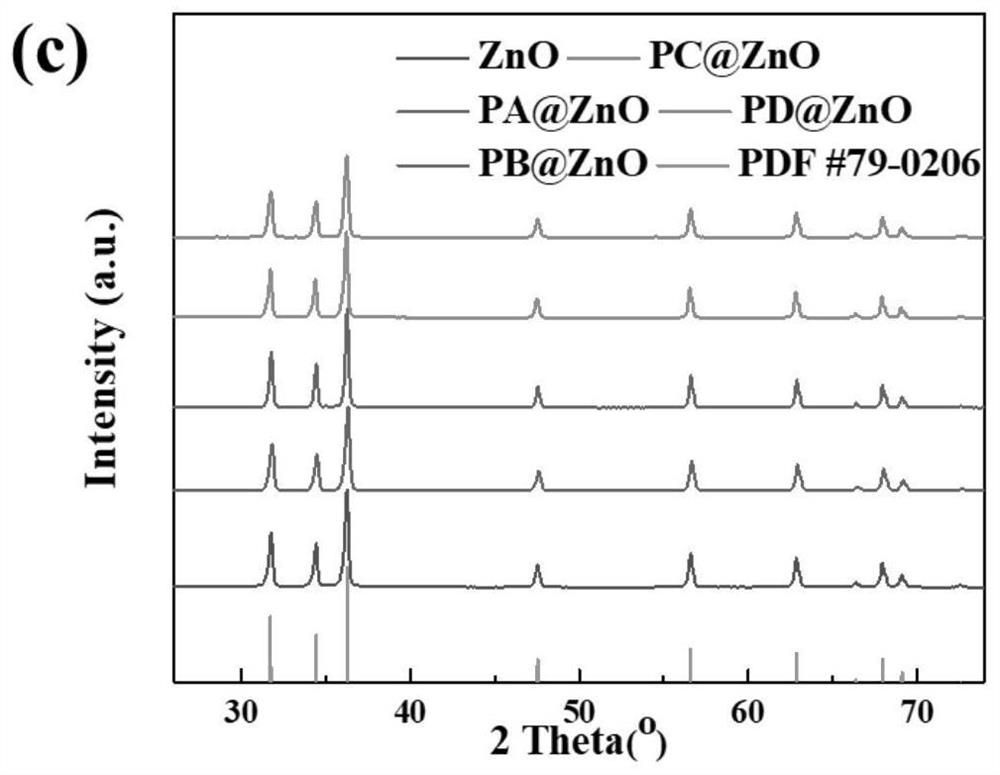

[0039] Step 1: Prepare zinc oxide modified powder. Pre-dissolve 6g of polyvinylpyrrolidone (PVP) in 50mL of isopropanol, stir at room temperature until clear, then pour 20g of zinc oxide powder into the solution, and stir overnight. The resulting mixture was poured into a centrifuge tube and centrifuged at 6000r / min for 10min. The supernatant was discarded and the remaining mixture was washed 3 times with ethanol and acetone to remove unabsorbed material. The mixture was then transferred to a 60°C oven to dry overnight. The mixture powder after drying is ball-milled or manually ground, and then sieved (100 microns), and the finer zinc oxide modified powder of finally making particle is ready for use.

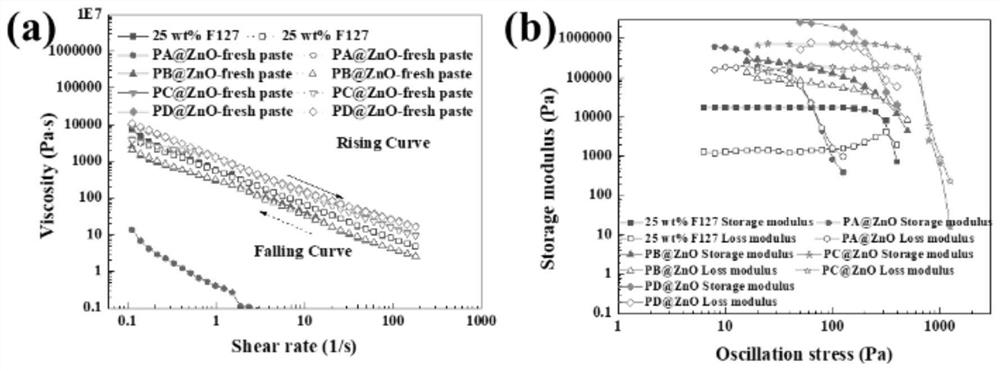

[0040] Step 2: Formulate the zinc oxide printable ink. Mix 6g of zinc oxide modified powder, 1.5mL of hydroxyethyl cellulose (HEC), 0.5mL of polyethyleneimine (PEI) and 2 drops of polyethylene glycol (PEG-400) and grind them with a mortar, grind until homogeneous.

[0041] ...

example 2

[0045] Step 1: Prepare zinc oxide modified powder. 7g of polyvinylpyrrolidone (PVP) was pre-dissolved in 50mL of isopropanol, stirred at room temperature until clear, then 25g of zinc oxide powder was poured into the solution, and stirred overnight. The resulting mixture was poured into a centrifuge tube and centrifuged at 6000r / min for 10min. The supernatant was discarded and the remaining mixture was washed 3 times with ethanol and acetone to remove unabsorbed material. The mixture was then transferred to a 60°C oven to dry overnight. The mixture powder after drying is ball-milled or manually ground, and then sieved (100 microns), and the finer zinc oxide modified powder of finally making particle is ready for use.

[0046] Step 2: Formulate the zinc oxide printable ink. Mix 7g of zinc oxide modified powder, 1.5mL of hydroxyethyl cellulose (HEC), 0.5mL of polyethyleneimine (PEI) and 2 drops of polyethylene glycol (PEG-400) and grind them with a mortar, grind until homoge...

example 3

[0051] Step 1: Prepare zinc oxide modified powder. Pre-dissolve 8g of polyvinylpyrrolidone (PVP) in 50mL of isopropanol, stir at room temperature until clear, then pour 20g of zinc oxide powder into the solution, and stir overnight. The resulting mixture was poured into a centrifuge tube and centrifuged at 6000r / min for 10min. The supernatant was discarded, and the remaining mixture was washed three times with ethanol and acetone to remove unabsorbed material. The mixture was then transferred to a 60°C oven to dry overnight. The mixture powder after drying is ball milled or manually ground, and then sieved (100 microns), and finally the zinc oxide modified powder with finer particles is prepared for use.

[0052] Step 2: Formulate the zinc oxide printable ink. Mix 8g of zinc oxide modified powder, 1.5mL of hydroxyethyl cellulose (HEC), 0.5mL of polyethyleneimine (PEI) and 3 drops of polyethylene glycol (PEG-400) and grind them with a mortar, grind until homogeneous.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com