Multi-region foldable adhesive film and method of making same

A multi-region, adhesive film technology, applied in the field of rights and interests on the date of application, can solve the problems of adhesive film processing characteristics deterioration, adhesive film stress relief ability reduction, adhesive film creases, etc., to improve the stress relief rate, Improving the effect of recovery properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0084] According to one embodiment of the invention, the method comprises the step of applying the adhesive composition to the substrate. The method of applying the adhesive composition is not particularly limited. Specifically, the method of applying the adhesive composition to the substrate may be an applicator method, a rod coater method, a comma coater method, or the like.

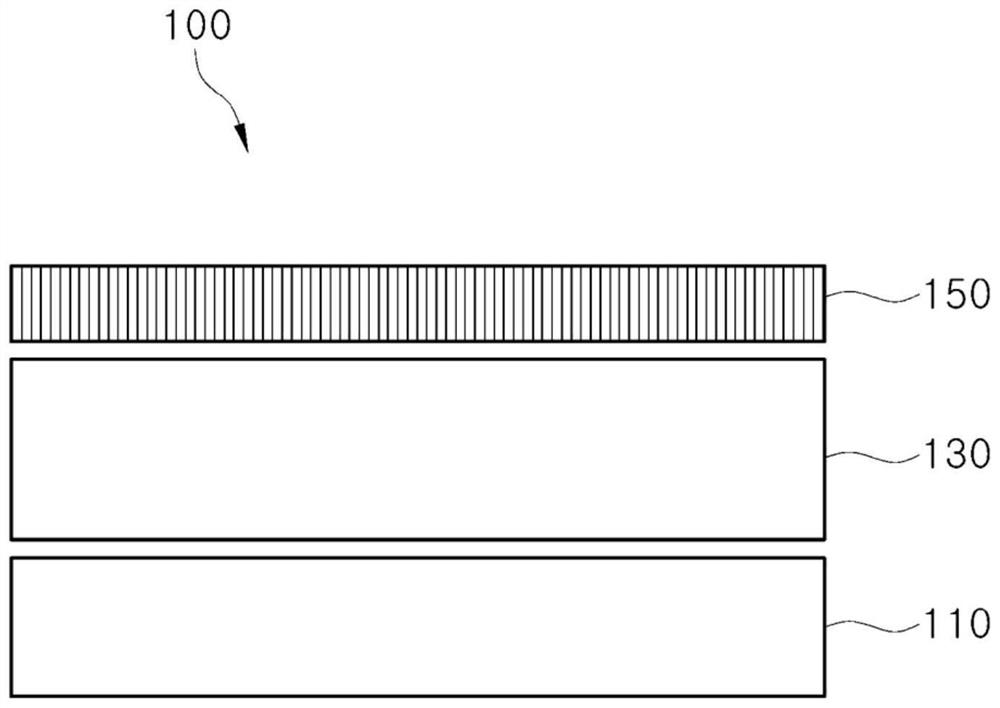

[0085] According to one embodiment of the present invention, the adhesive layer may have a thickness of 10 μm to 100 μm. Specifically, the adhesive layer may have a thickness of 10 μm to 80 μm, 10 μm to 60 μm, or 10 μm to 40 μm. By adjusting the thickness of the adhesive layer within the above range, it is possible to adjust the step coverage property and adhesive strength of the foldable adhesive film.

[0086] According to one embodiment of the present invention, the foldable adhesive film comprises a substrate disposed on one surface of the adhesive layer. In particular, by including the substrat...

Embodiment 1

[0105] (1) Preparation of copolymer

[0106] A monomer mixture was introduced into a 1L reactor, the monomer mixture comprising a mixture containing about 97.98% by weight of 2-ethylhexyl acrylate (2-EHA) and about 2.02% by weight of acrylic acid (AA) and based on 100 parts by weight The mixture was 1.01 parts by weight of benzophenone methacrylate (BPMA), and then ethyl acetate (EAc) was introduced as a solvent. Next, the reactor was purged with nitrogen for about 1 hour to remove oxygen and then maintained at a temperature of 62°C. After homogenizing the monomer mixture, 400 ppm of azobisisobutyronitrile (AIBN) as a reaction initiator and 400 ppm of n-dodecylmercaptan (n-DDM) as a chain transfer agent were added thereto, and the mono body mixture reaction. After the reaction was completed, the reaction product was diluted with ethyl acetate, thereby preparing a copolymer having a weight average molecular weight of 2,000,000.

[0107] (2) Preparation of adhesive compositio...

Embodiment 2

[0112] An adhesive film was produced in the same manner as in Example 1, except that a monomer mixture containing about 98.48% by weight of 2-ethylhexyl acrylate (2- EHA) and about 2.02% by weight of acrylic acid (AA) and about 0.51 parts by weight of benzophenone methacrylate (BPMA), based on 100 parts by weight of the mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap