Calcium phosphate bioactive scaffold capable of regulating and controlling cell adhesion performance

A technology of calcium phosphate and cell adhesion, which is applied in tissue regeneration, ceramic products, prostheses, etc., achieving good market application prospects, promoting cell adhesion, and simple process methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

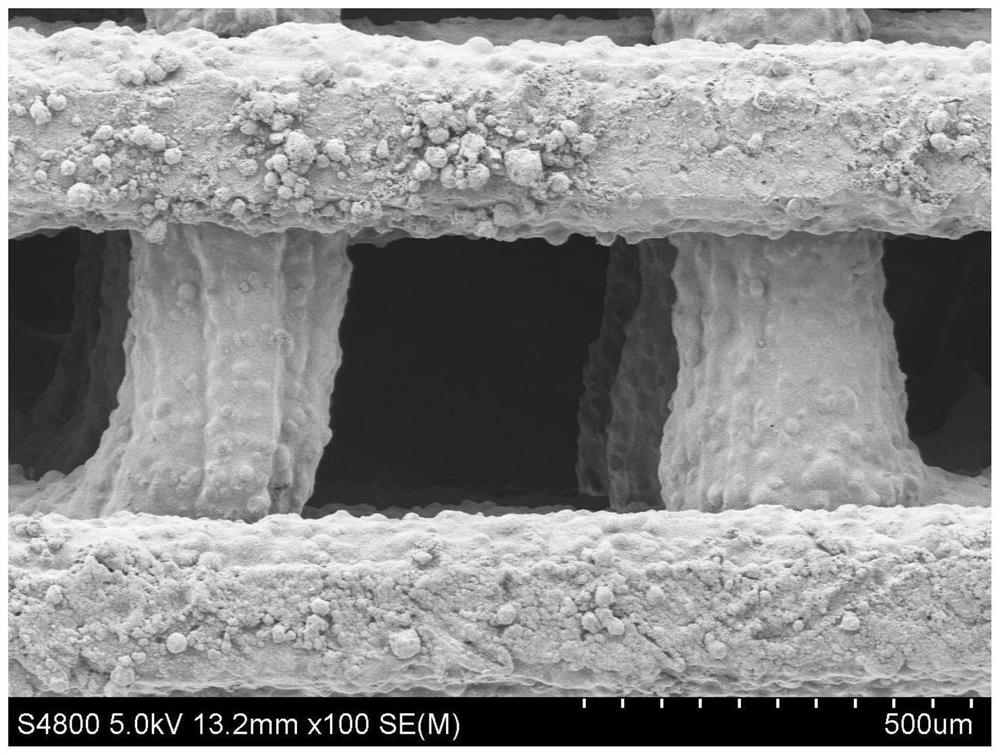

[0030] (1) Extrusion 3D printing equipment was used to prepare ceramic repair brackets. Firstly, 10% alcohol solution of polyvinyl butyral (PVB, molecular weight: 170000-250000) and hydroxyapatite powder are mixed evenly with a defoamer. Put the mixed ceramic slurry into the printing cylinder for 3D printing. Among them, the printing speed is 8mm / s, the printing layer thickness is 0.32mm, the extrusion pressure is 0.3MPa, and the pore spacing is 1mm.

[0031] (2) The printed hydroxyapatite scaffold was sintered at high temperature in a muffle furnace to remove the binder inside the scaffold and solidify the ceramic scaffold. The sintering temperature used was 1200° C. and the sintering time was 2 hours. After sintering, the scaffold had a macroscopic porosity of 69% and an overall shrinkage of 35%.

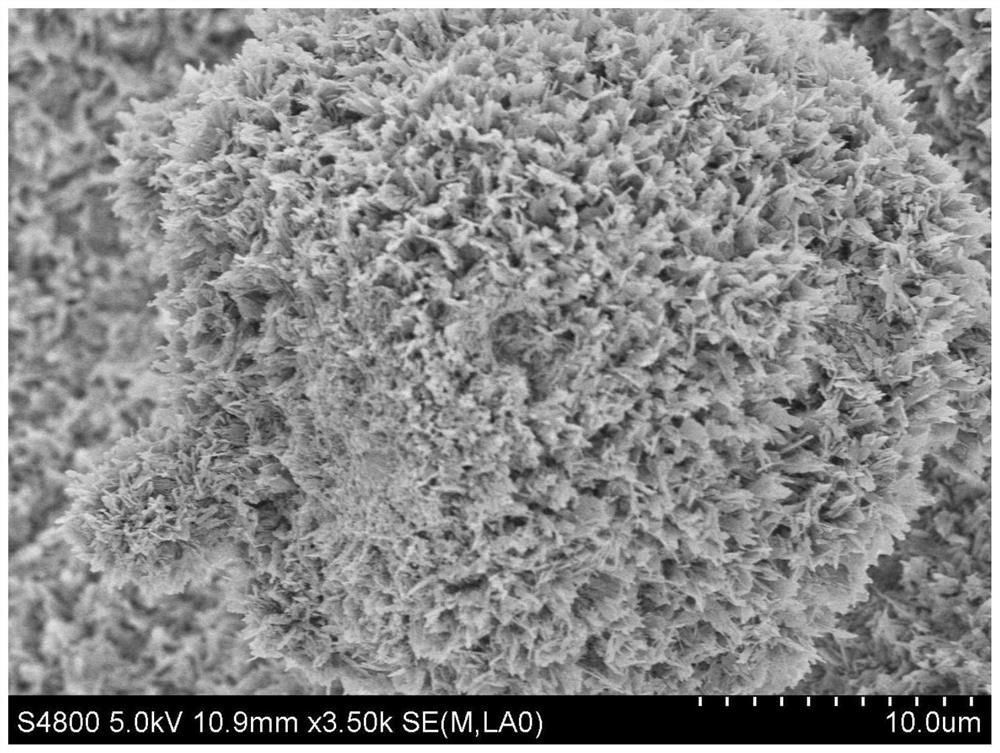

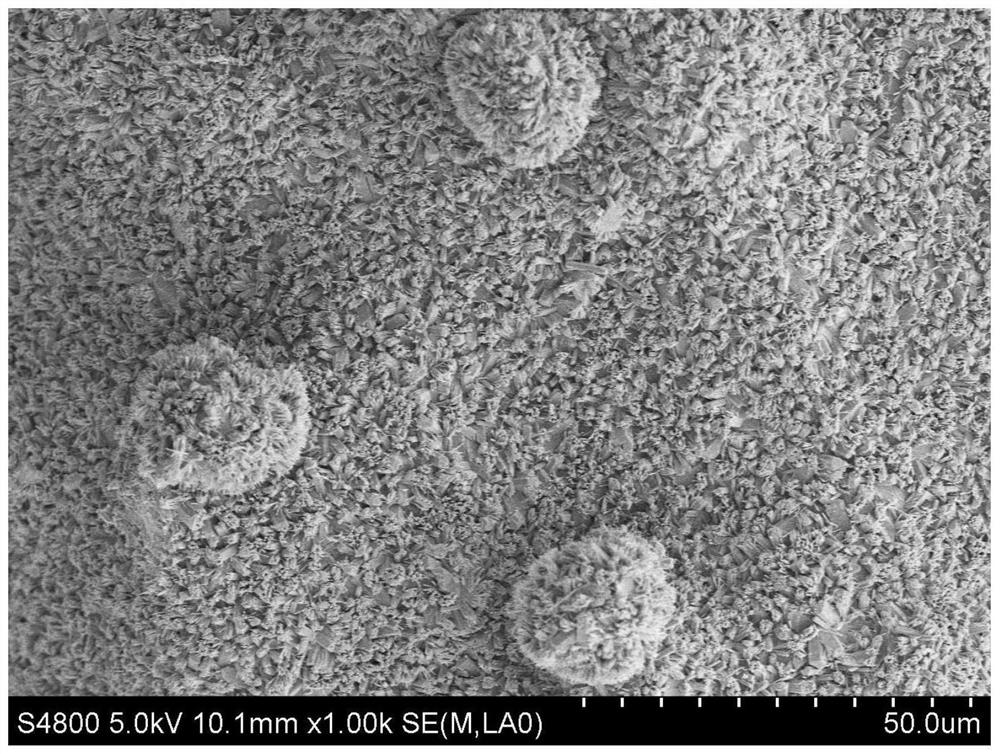

[0032] (3) The calcium phosphorus micro-nano active coating of the scaffold was prepared by hydrothermal method to increase the adhesion and recruitment of sintered ceramics to...

Embodiment 2

[0036] Tricalcium phosphate was selected as the printing material. According to the method of Example 1, the base part of the stent was prepared by 3D printing, and then the calcium phosphorus micro-nano active coating on the surface was prepared by a hydrothermal method. The selection of other parameters and the preparation process were the same as in Example 1, except that the water The heat medium is HNO with a pH of 4 3 solution. Finally, a ceramic stent with a micron-sized calcium-phosphorus active coating is obtained. Since tricalcium phosphate is easy to release a large amount of calcium ions in an acidic solution, a ceramic stent with a coating can be obtained only by using an acidic solution as a hydrothermal medium. Its coated rod-like structure is about 50 μm in length.

Embodiment 3

[0038] Biphasic calcium phosphate is selected as the printing material. According to the method of Example 1, the base part of the stent was prepared by 3D printing, and then the surface coating was prepared by the hydrothermal method. The selection of other parameters and the preparation process were the same as in Example 1, except that the pH of the hydrothermal medium was selected to be 4HNO 3 solution. The end result is a ceramic stent with a micron-sized coating. Since the tricalcium phosphate inside the biphasic calcium phosphate is easy to release a large amount of calcium ions in an acidic solution, a ceramic stent with a coating can be obtained only by using an acidic solution as a hydrothermal medium. Its coated rod-like structure is about 5 μm in length.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com