Intrinsic black polyimide as well as preparation method and application thereof

A technology of black polyimide and polyimide, applied in the field of material science, can solve the problems that polyimide has not been reported, and achieve the effect of improving visible light absorption capacity, excellent solubility, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

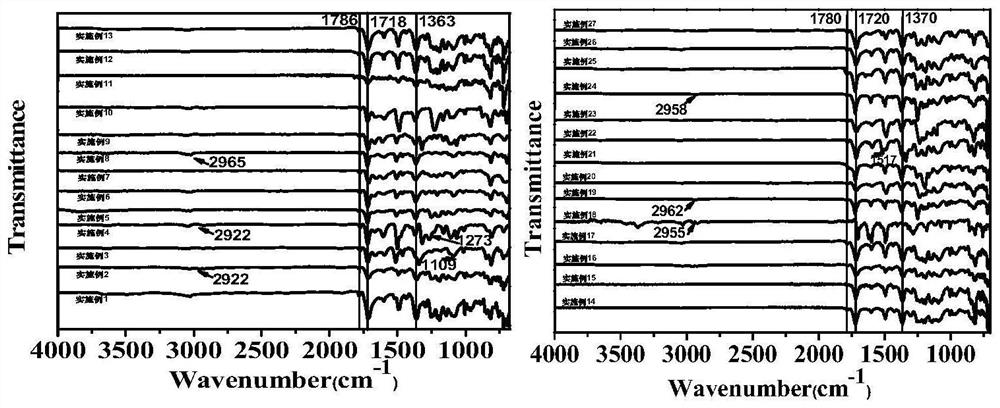

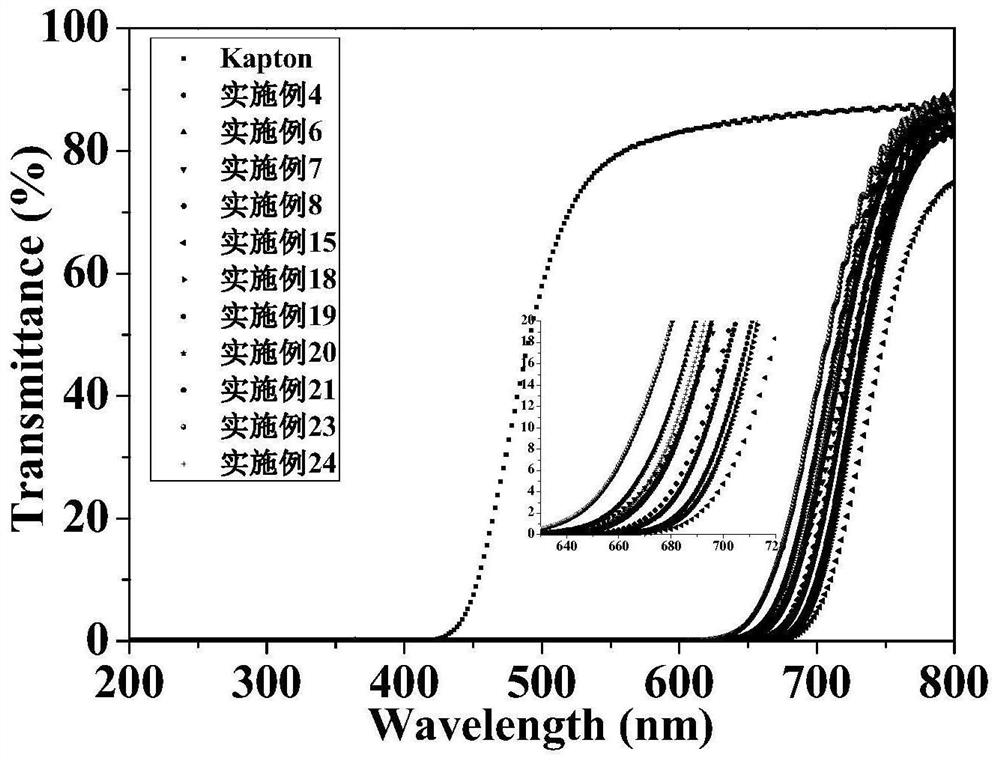

[0037] In a clean room, add 2.8666g (3.5mmol) 3,4-di([1,1'-biphenyl]-4-yl)-2,5-bis(4- (4-aminonaphthalen-1-yl)phenyl)cyclopenta-2,4-dienone and 18.4ml of dry N-methylpyrrolidone (NMP), stir to dissolve it, add 4,4'-(hexafluoroisopropene) Diphthalic anhydride (6FDA) 1.5548g (3.5mmol) with a solid content of about 18% was reacted at 0°C for 8h to obtain the corresponding PAA glue.

[0038] The imidization reagent was prepared at a volume ratio of NMP:acetic anhydride:isoquinoline=2:2:1, 6ml of the imidization reagent was added dropwise to the PAA glue, and the chemical imidization was carried out by stirring at room temperature for 1 hour. Squeeze the chemically imidized PI glue on a clean glass plate, and control the thickness of the liquid film by adjusting the effective height of the scraper. After heating up to 120°C in a high-temperature blast drying oven, keep the temperature for 1 hour to remove the solvent, then transfer to a vacuum drying oven to quickly raise the temp...

Embodiment 2

[0042] In a clean room, add 1.9025g (2mmol) 2,5-bis(4'-amino-[1,1'-biphenyl]-3-yl)-3,4-bis to a 50ml round bottom flask under nitrogen protection (4-(9,9-dimethyl-9H-fluoren-2-yl)phenyl)cyclopenta-2,4-dienone and 21.2ml of dry N,N-dimethylacetamide (DMAc), stirred to dissolve , then add 0.8885g (2mmol) of 6FDA, the solid content is about 13%, and react at -10°C for 48h to obtain the corresponding PAA glue.

[0043] The imidization reagent was prepared at a volume ratio of DMAc:acetic anhydride:pyridine=6:3:1, 5ml of the imidization reagent was added dropwise to the PAA glue, and the chemical imidization was carried out at 30°C for 1.5h. Squeegee-coat the chemically imidized PI glue on a clean glass plate, heat it up to 140°C in a blast drying oven, then keep the temperature constant for 0.8h to remove the solvent, then transfer it to a vacuum drying oven and quickly raise the temperature to 440°C, and keep the temperature constant After 10 minutes, the PI film was fully imidi...

Embodiment 3

[0047] In a clean room, add 2,5-bis(4”-amino-[1,1’:4’,1”-terphenyl]-4-yl)-3,4 to a 50ml round bottom flask under argon protection -bis(3-fluorophenyl)cyclopenta-2,4-dienone 3.0195g (4mmol) and 20ml of dry N,N-dimethylformamide (DMF), after stirring to dissolve, add 6FDA 1.7770g (4mmol), the solid content About 20%, reacted at 0°C for 8 hours to obtain the corresponding PAA glue.

[0048] The imidization reagent was prepared at a volume ratio of DMF:acetic anhydride:isoquinoline=6:3:1, and 6ml of the imidization reagent was added dropwise to the PAA glue solution, and the chemical imidization was carried out by stirring at 40°C for 2 hours. Scrape-coat the chemically imidized PI glue on a clean glass plate, heat it up to 80°C in a blast drying oven, then keep the temperature constant for 0.6h, and then keep the temperature at 160°C for 1h to remove the solvent, and then transfer it to a vacuum drying oven for rapid heating To 330°C, and keep the temperature for 30 minutes to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com