Automobile finish paint and preparation method thereof

A technology for automotive topcoats and coatings, applied in the field of automotive topcoats and their preparations, can solve the problems of non-densification, poor mechanical properties, soft resin, etc., and achieve the effect of excellent antifouling and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The present embodiment provides a kind of automobile finish paint and preparation method thereof, wherein, the automobile finish paint comprises the component of following parts by weight: 20 parts of polyurethane acrylate resins, 20 parts of epoxy acrylate resins, 5 parts of chitosan , 8 parts of polychlorotrifluoroethylene / vinyl ether resin, 2 parts of hydrophobically modified nano-silicon dioxide, 9 parts of nano-silicon carbide, 0.5 parts by weight of dispersant propylene oxide butyl ether, defoamer polyether modified silicone 0.1 parts by weight, leveling agent polyether polyester modified organosiloxane 0.2 parts by weight, anti-settling agent 0.5 parts by weight, barite powder filler 3 parts by weight.

[0031] The preparation method of above-mentioned automobile finish coating, comprises the steps:

[0032] S1: Preparation of hydrophobically modified nano-silica: Stir nano-silica and 0.1mol / L NaOH solution at room temperature for 50 minutes, filter out the lye a...

Embodiment 2

[0035] The present embodiment provides a kind of automobile finish paint, and the difference with embodiment 1 only is that the composition of paint is different, and present embodiment automobile finish paint comprises the component of following parts by weight:

[0036] 18 parts of polyurethane acrylate resin, 12 parts of epoxy acrylate resin, 3 parts of chitosan, 15 parts of polyvinyl fluoride resin, 3 parts of hydrophobically modified nano-silica, 7 parts of nano-silicon carbide, dispersant propylene oxide benzene 0.2 parts by weight of base ether, 0.5 parts by weight of polyether modified silicone as antifoaming agent, 0.1 part by weight of polyether polyester modified organosiloxane as leveling agent, 0.5 parts by weight of anti-settling agent, and 5 parts by weight of pigment and filler.

Embodiment 3

[0038] The present embodiment provides a kind of automobile finish paint, and the difference with embodiment 1 only is that the composition of paint is different, and present embodiment automobile paint finish comprises the component of following parts by weight:

[0039] 18 parts of polyurethane acrylate resin, 6 parts of epoxy acrylate resin, 3 parts of chitosan, 12 parts of polyvinyl fluoride resin, 4 parts of hydrophobically modified nano-silica, 4 parts of nano-silicon carbide, dispersant cyclopolyglycidol 0.5 parts by weight of ether, 0.1 parts by weight of polyether modified silicone as antifoaming agent, 0.1 part by weight of polyether polyester modified organosiloxane as leveling agent, 0.3 parts by weight of anti-settling agent, and 4 parts by weight of pigments and fillers.

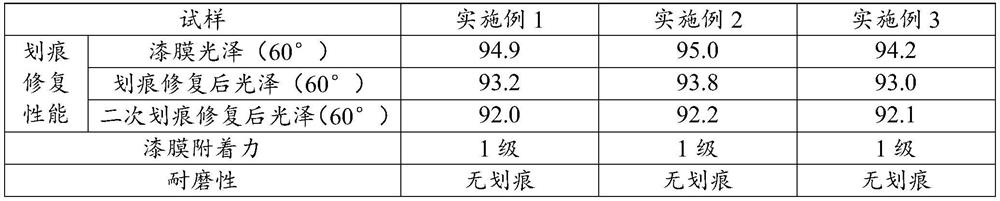

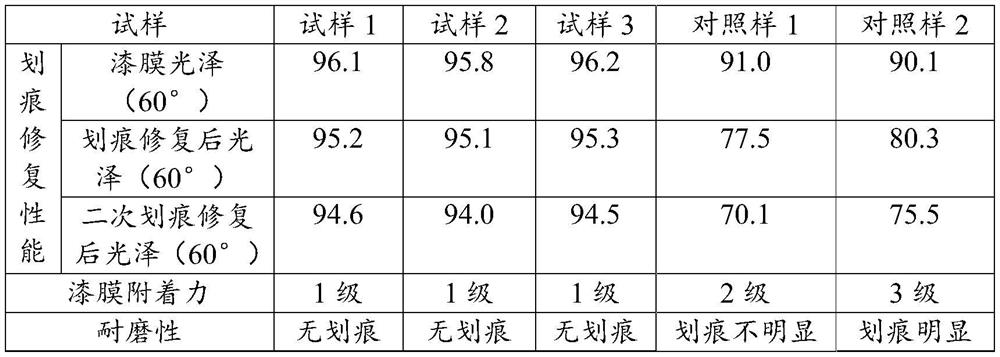

[0040] Refer to the method specified in GB / T1743-89 to detect the self-healing repair performance of the coatings in Examples 1-3, and use the gloss retention rate and scratch repair time after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com