Nitrogen oxide tail gas treatment process

A nitrogen oxide and tail gas treatment technology, applied in gas treatment, nitrous oxide capture, climate sustainability, etc., can solve the problems of limited reaction absorption, ineffective effect, poor mass transfer effect, etc. Simple, environment-friendly, and low-dose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

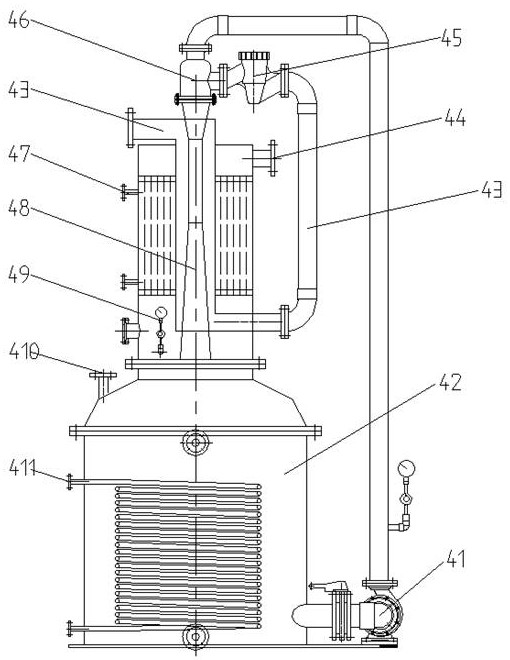

Image

Examples

Embodiment 1

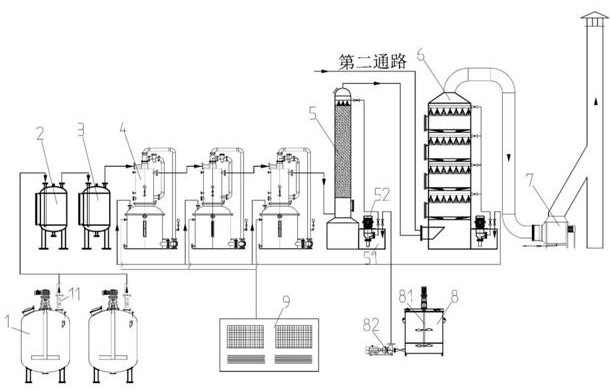

[0034] This embodiment discloses a nitrogen oxide tail gas treatment process, which specifically includes the following steps:

[0035] (1) The nitrogen oxide tail gas of the gallium nitrate reactor is first condensed by the gas-liquid separator, and the entrained liquid is recovered, and the gas enters the clear water bubbling absorption tank, and part of the nitrogen oxide reacts with water to form nitric acid or nitrous acid, which is recovered;

[0036] (2) The remaining nitrogen oxides enter the hydrogen peroxide bubbling absorption tank with the tail gas in step (1) to react with hydrogen peroxide, and oxidize the nitrogen monoxide in the nitrogen oxides into nitrogen dioxide. During the process, keep the hydrogen peroxide solution in the hydrogen peroxide bubbling absorption tank The concentration is 30~35%;

[0037] (3) Pass the nitrogen oxide tail gas treated in step (2) into the water jet vacuum unit to react with the prepared urea cycle absorption liquid to generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com