Preparation method of mercury ion imprinting adsorption material

A technology of imprinted adsorption and mercury ions, applied in separation methods, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve problems such as difficult application treatment, incomplete treatment of mercury wastewater, secondary pollution, etc., and achieve good adsorption capacity , excellent regenerative ability, excellent adsorption ability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

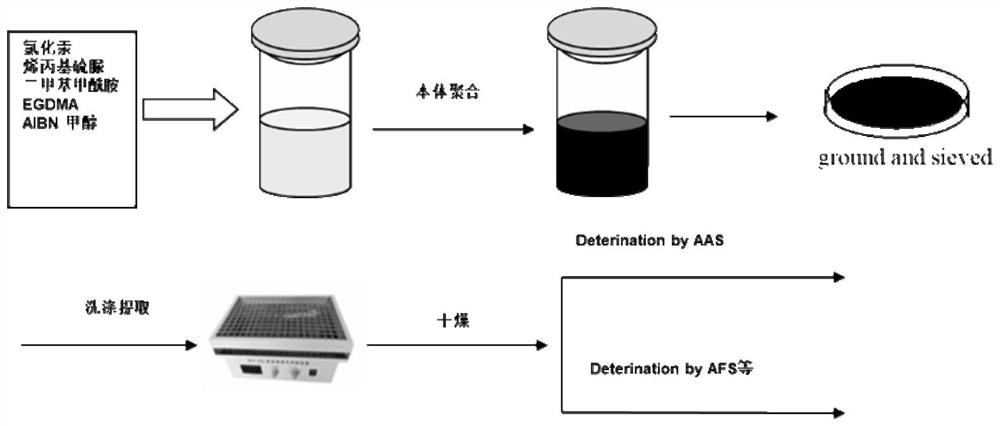

[0024] Add 4mmol of allylthiourea to 2mmol of mercuric chloride solution according to the molar ratio of 1:2, dissolve in 10mL of methanol, add 10mL of N,N-dimethylformamide, shake for 2 hours, then add 40mmol of ethylene glycol dimethyl Methyl acrylate, 1.12 mmol of azobisisobutyronitrile initiator, shaken for 2 hours.

[0025] The above solution was passed through nitrogen gas for 10 minutes under the condition of ice bath, and then shaken in a water bath at 60°C for 24 hours.

[0026] The resulting polymer was crushed and sieved to 30-38.5 μm polymer particles.

[0027] Then use 0.5% thiourea + 0.5mol / L HNO 3 Wash until free of Hg 2 + check out. Vacuum drying at 35°C overnight to obtain mercury ion-imprinted polymer (MIP).

[0028] The synthesis steps of NIP are exactly the same as those of MIP, except that template molecules are not added during synthesis. The obtained polymers were subjected to adsorption experiments and characterizations. The specific synthesis and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com