Continuous flow preparation method of 4 '-fluoro-2-phenyl acetophenone

A technology of phenylacetophenone and fluorobenzene is applied in the field of pharmaceutical synthesis technology, and can solve the problems of corrosion of reaction equipment, harm to human body, generation of impurities, etc., and achieve the effect of reducing defluorination impurities and improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

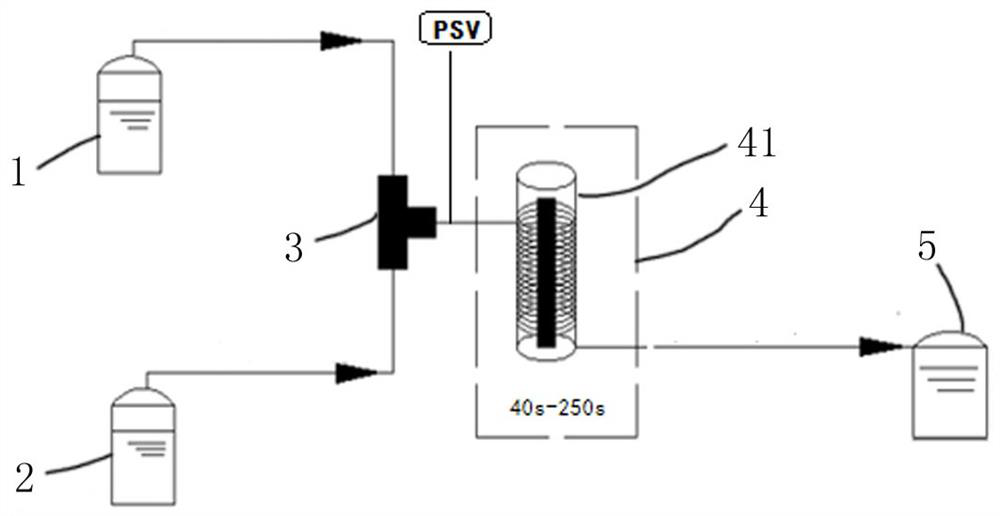

[0049] The present invention adopts continuous flow reaction system to carry out continuous preparation of 4'-fluoro-2-phenylacetophenone, such as Figure 1-3 As shown, the continuous flow reaction system includes a first raw material storage tank 1, a second raw material storage tank 2, a T-shaped gradient mixer 3, a coil microreactor 4, and a product collection tank 5;

[0050] The first raw material storage tank 1 is used for storing phenylacetyl chloride, aluminum trichloride and organic solvent I, and the second raw material storage tank 2 is used for storing fluorobenzene and organic solvent II.

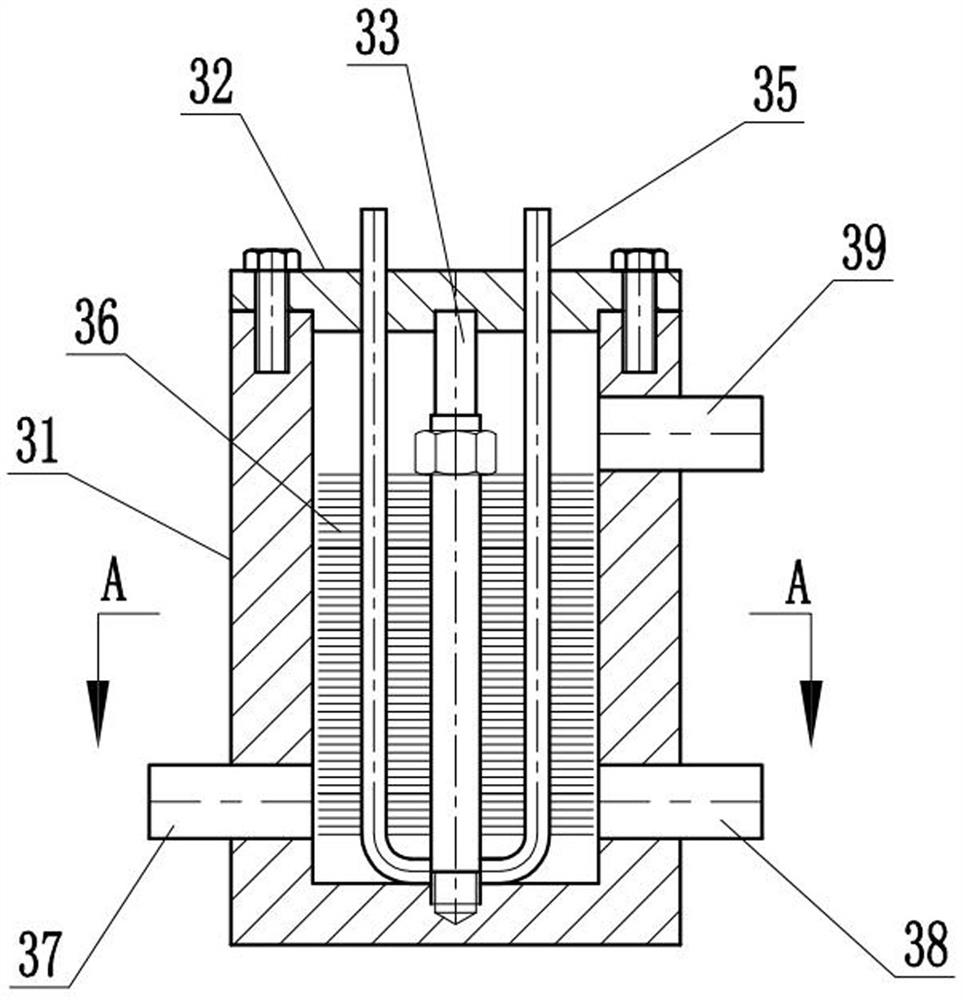

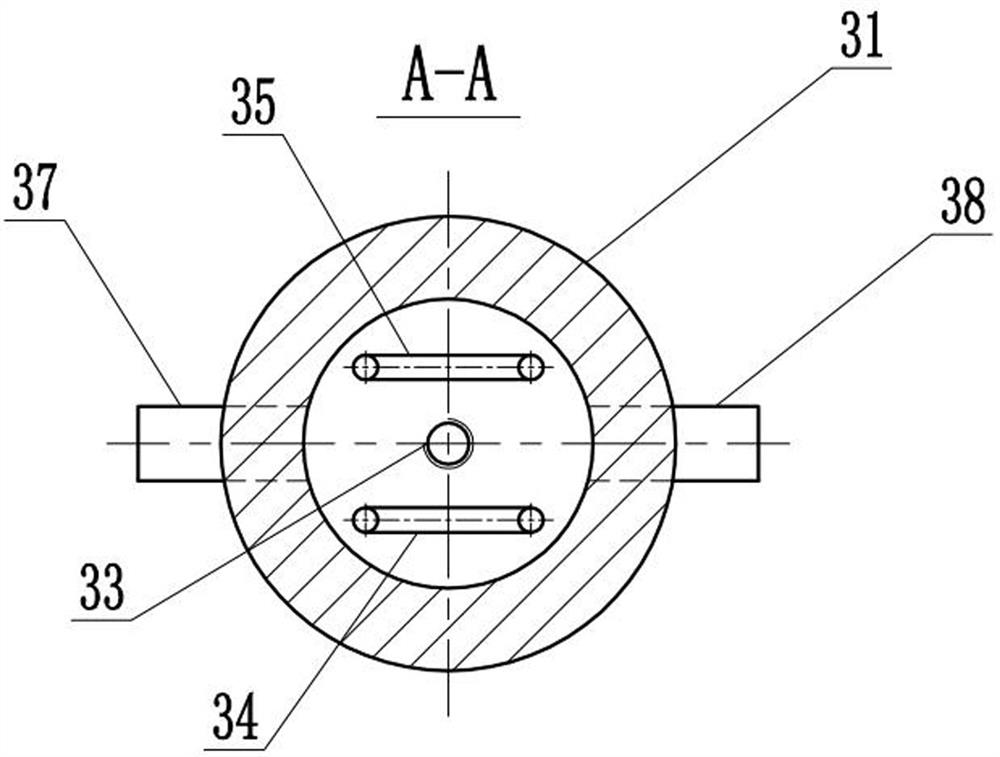

[0051] Such as Figure 2-3 As shown, the T-shaped gradient mixer 3 is a cylindrical structure made of polytetrafluoroethylene, with a diameter of 8 cm, a wall thickness of 1-1.5 cm, and a body height of 20 cm, including a reactor body 31 and a top cover arranged on the top of the reactor body 31 32. The top cover 32 is detachably connected to the side wall of the reactor body ...

Embodiment 2

[0063] A continuous flow preparation method of 4'-fluoro-2-phenylacetophenone, using the continuous flow reaction system in Example 1 to continuously prepare 4'-fluoro-2-phenylacetophenone, the specific steps are as follows ;

[0064] (1) Continuously prepare material A solution in the first raw material storage tank 1: Dissolve aluminum trichloride (16.001 g, 0.12 mol) and phenylacetyl chloride (15.459 g, 0.1 mol) in 300 mL of trichloro methane, and in the first raw material storage tank 1, the temperature of the material A solution is maintained at 10°C to 20°C through heat exchange equipment;

[0065] (2) Continuously prepare material B solution in the second raw material storage tank 2: Dissolve fluorobenzene (10.572 g, 0.11 mol) in 200 mL chloroform under stirring conditions, and pass through the second raw material storage tank 2 Heat exchange equipment keeps the temperature of material B solution at 10°C~20°C;

[0066] (3) Start the first feed pump and the second feed...

Embodiment 3

[0070] A continuous flow preparation method of 4'-fluoro-2-phenylacetophenone, using the continuous flow reaction system in Example 1 to continuously prepare 4'-fluoro-2-phenylacetophenone, the specific steps are as follows ;

[0071] (1) Continuously prepare material A solution in the first raw material storage tank 1: Dissolve aluminum trichloride (16.001 g, 0.12 mol) and phenylacetyl chloride (15.459 g, 0.1 mol) in 300 mL of trichloro methane, and in the first raw material storage tank 1, the temperature of the material A solution is maintained at 10°C to 20°C through heat exchange equipment;

[0072] (2) Continuously prepare material B solution in the second raw material storage tank 2: Dissolve fluorobenzene (10.572 g, 0.11 mol) in 200 mL chloroform under stirring conditions, and pass through the second raw material storage tank 2 Heat exchange equipment keeps the temperature of material B solution at 10°C~20°C;

[0073](3) Start the first feed pump and the second feed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com