Preparation method of mesoporous zeolite polymer material

A technology of polymer material and mesoporous zeolite, which is applied in the field of preparation of mesoporous zeolite polymer materials, can solve the problems of skin burns, increase of wound temperature, influence on wound healing, etc., and achieve the effect of alleviating the problem of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

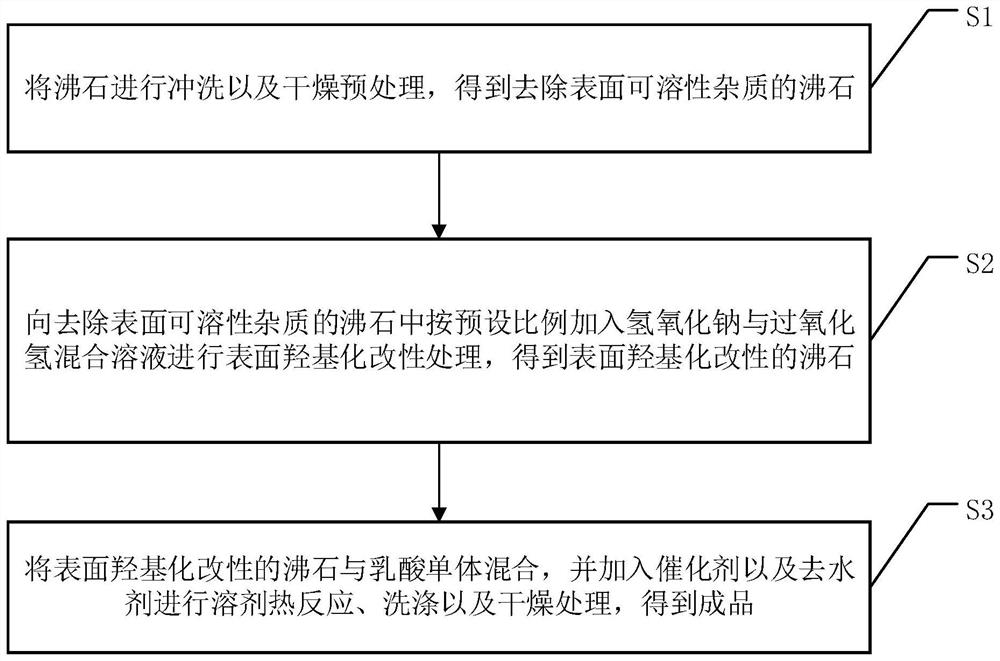

[0033] Specifically, the preparation method of the mesoporous zeolite polymer material, hereinafter referred to as the preparation method, includes the following steps:

[0034] S1: washing and pre-drying the zeolite to obtain the zeolite whose surface soluble impurities are removed;

[0035] S2: adding a mixed solution of sodium hydroxide and hydrogen peroxide according to a preset ratio to the zeolite from which surface soluble impurities have been removed to carry out surface hydroxylation modification treatment to obtain surface hydroxylation-modified zeolite;

[0036] S3: Mix the zeolite modified by surface hydroxylation with lactic acid monomer, add catalyst and dewatering agent to carry out solvothermal reaction, washing and drying treatment to obtain the finished product.

[0037] It is worth mentioning that, as a bio-based polymer material, polylactic acid has attracted much attention due to its good antibacterial ability, biological activity, biocompatibility and bio...

Embodiment 1

[0055] (1) Zeolite pretreatment: Select zeolite with a particle size range of 70-900 μm, wash it several times with deionized water to wash away the soluble inorganic matter on the surface, and then dry it in a digital display electric heating constant temperature drying oven at 60°C for 12 hours.

[0056] (2) Zeolite surface hydroxylation modification: Mix the pretreated zeolite with the mixed solution of sodium hydroxide and hydrogen peroxide at a ratio of 0.3g:30ml, ultrasonically disperse for 10min, impregnate for 30min, heat and stir at 60°C for 2h, After filtration, wash with ethanol and deionized water for several times, and then vacuum-dry at 60°C for 12 hours to obtain surface hydroxylation-modified zeolite, wherein the sodium hydroxide and hydrogen peroxide in the mixed solution of sodium hydroxide and hydrogen peroxide are in the aqueous solution The proportions are 0.5% and 2% respectively.

[0057] (3) Add 2 g of modified zeolite into a beaker, add 10 g of lactic ...

Embodiment 2

[0061] (1) Zeolite pretreatment: select zeolite with a particle size range of 70-900 μm, wash it several times with deionized water to remove soluble inorganic matter on the surface, and then dry it in a digital display electric heating constant temperature drying oven at 70°C for 8 hours.

[0062] (2) Zeolite surface hydroxylation modification: Mix the pretreated zeolite with the mixed solution of sodium hydroxide and hydrogen peroxide at a ratio of 0.5g:50ml, ultrasonically disperse for 20min, impregnate for 40min, heat, stir and reflux at 80°C for 2h, After filtration, wash with ethanol and deionized water for several times, and then vacuum-dry at 70°C for 8 hours to obtain surface hydroxylation-modified zeolite, wherein the sodium hydroxide and hydrogen peroxide in the mixed solution of sodium hydroxide and hydrogen peroxide are in the aqueous solution The proportions are 0.5% and 2% respectively.

[0063] (3) Add 3g of modified zeolite into a beaker, add 15g of lactic aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com