Layered microneedle, layered microneedle contraceptive system and preparation method and application of layered microneedle contraceptive system

A micro-needle and needle-tip technology, which is applied in the field of pharmaceutical preparations, can solve problems such as contraceptive failure, physical injury to users, and limited release rate, and achieve the effects of avoiding drug waste, meeting the needs of contraceptive duration, and avoiding discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of layered microneedles:

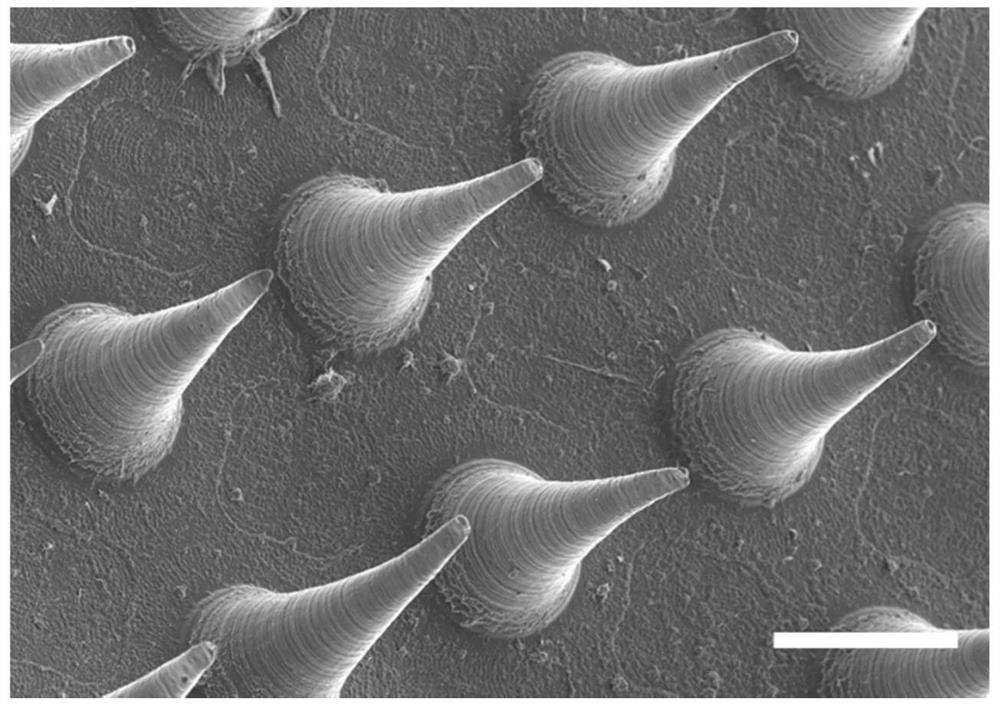

[0046] (1) A layered microneedle patch was prepared using a polydimethylsiloxane (PDMS) mold with a conical hole array (Taizhou Microchip Pharmaceutical Technology Co., Ltd.). All arrays on the mold contain 10×10 needles, the array area is 8mm×8mm, the conical hole array contains 10×10 needles, the center-to-center spacing of each needle tip is 650 μm, and the height of each needle is 800 μm.

[0047] (2) Prepare a PVP (90k molecular weight) aqueous solution with a concentration of 300mg / ml to form a needlepoint pouring fluid.

[0048] (3) Use a straw to draw 200 μL of the prepared needle tip pouring solution and apply it on the PDMS mold, and centrifuge at 4000 rpm for 20 minutes to fill the microcavity of the PDMS mold and remove excess solution remaining on the surface of the mold.

[0049] (4) Weigh 300 mg of PS particles and dissolve in 1 mL of dioxazole solution (1,4-dioxane) to obtain a PS (molecular weight of 260k) dioxazo...

Embodiment 2

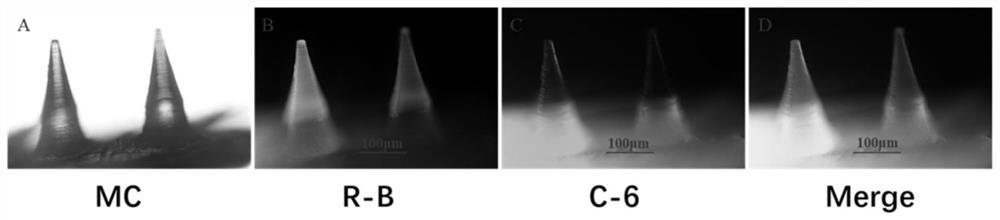

[0053] Fabrication of fluorescent layered microneedles

[0054] Weigh 1 μg of rhodamine B (R-B) powder and dissolve it in 2 mL of 300 mg / mL PVP aqueous solution to form a needle tip pouring solution, weigh 1 μg of coumarin 6 (C-6) powder and dissolve it in 2 mL of 300 mg / mL PS In the bisoxazole solution as the base pouring liquid, other preparation steps are the same as in Example 1.

[0055] like figure 2 The MC shown in (A) is a bright-field photo of fluorescent layered microneedles. figure 2 R-B shown in (B) is the fluorescence photo of the needle tip, figure 2 C-6 shown in (C) is the fluorescent photo of the substrate, figure 2 The Merge shown in (D) is the merged result of the R-B needle tip and the C-6 substrate. From the results of these four fluorescent photos, it can be known that the double-layer microneedle was successfully prepared.

Embodiment 3

[0057] Preparation steps of LNG@PCL nanospheres

[0058] (1) Weigh 50 mg of polycaprolactone (PCL) and 10 mg of levonorgestrel LNG, mix and dissolve in 3 mL of dichloromethane (DCM) to obtain a DCM mixed solution.

[0059] (2) Add the DCM mixed solution obtained in step (1) into 15 mL of PVA aqueous solution with a concentration of 50 mg / ml, and ultrasonically break in an ice bath for 30 minutes to form an O / W emulsion.

[0060] (3) The O / W emulsion obtained in the stirring step (2) was removed by volatilization to remove the DCM in the emulsion, and the stirring time was 24 hours.

[0061] (4) After removing DCM, the prepared LNG@PCL nanosphere precipitate was collected by centrifugation at 1000 rpm for 10 minutes, and washed 3 times with distilled water.

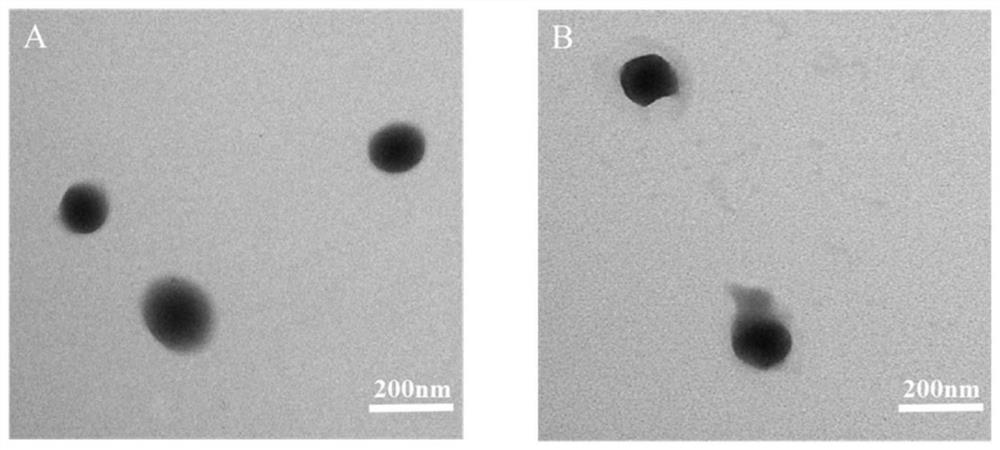

[0062] (5) Resuspend the washed LNG@PCL nanospheres in 20mg / mL aqueous mannitol solution, freeze-dry the resuspension, as image 3 As shown in (A), smooth and round LNG@PCL nanospheres are generated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com