Method for constructing amorphous photonic crystal on substrate

A technology of photonic crystals and substrates, which is applied in the direction of surface coating liquid devices, coatings, pretreatment surfaces, etc., can solve the problems of reducing the use prospects and strong limitations of amorphous photonic crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

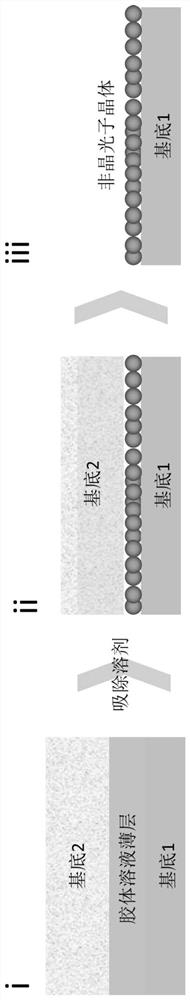

Method used

Image

Examples

Embodiment 1

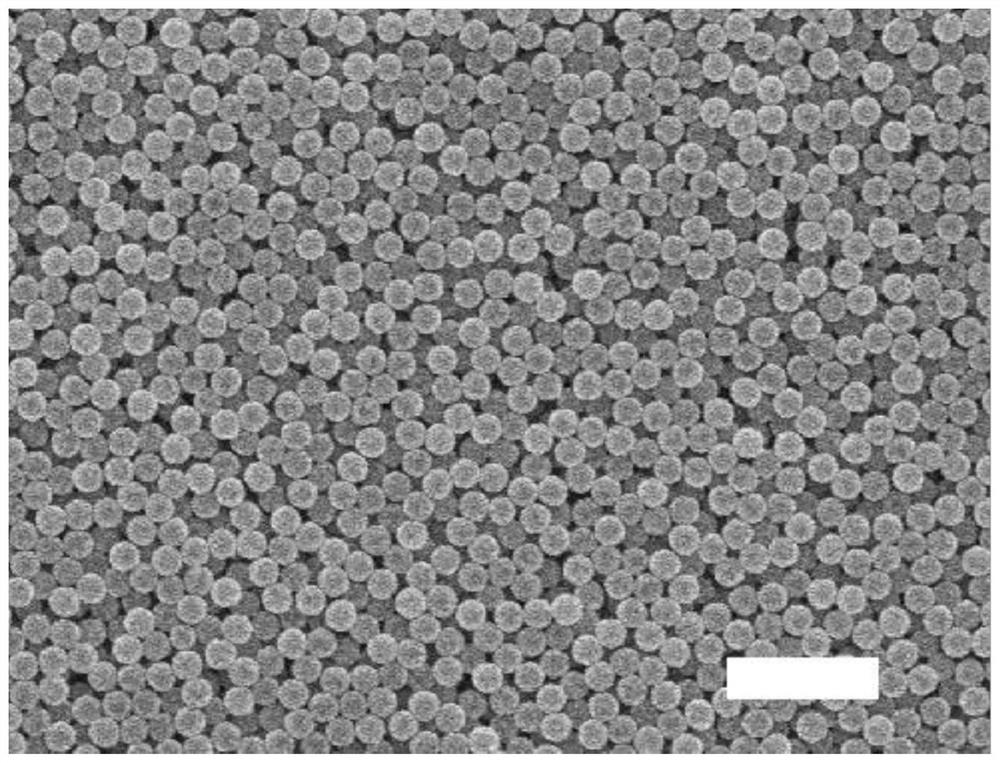

[0053] 1) Under normal temperature and pressure, monodisperse SiO with a particle size of 215nm 2 The microspheres are dispersed in a mixed solution of water, ethanol and methanol with a volume ratio of 1:1:1 to obtain a colloidal particle suspension with a mass fraction of 10%.

[0054] 2) Take a 3cm*3cm glass sheet, use plasma cleaning equipment to make the substrate hydrophilic, and ultrasonically clean it in ethanol solution for 3 times, and dry it with nitrogen.

[0055] 3) Take a porous alumina sheet of 3cm*3cm, put it in a glass bottle with a volume of 0.5L, add 1ml of ethanol solution containing 5% propylsiloxane by volume, and heat it in an oven at 70 degrees Celsius for 12 hours.

[0056] 4) Drop 50 microliters of the colloidal particle suspension onto the glass sheet, and use a 18# roll-coating rod to build a thin layer of nanosphere emulsion with a thickness of 20 microns on the surface of the glass sheet.

[0057] 5) Put the modified porous alumina sheet upside d...

Embodiment 2

[0059] 1) Under normal temperature and pressure, disperse monodisperse MOF colloidal particles with a particle size of 250 nm in a mixed solution with a methanol / water volume ratio of 4:1 to obtain a colloidal particle suspension with a solid content of 10 wt%.

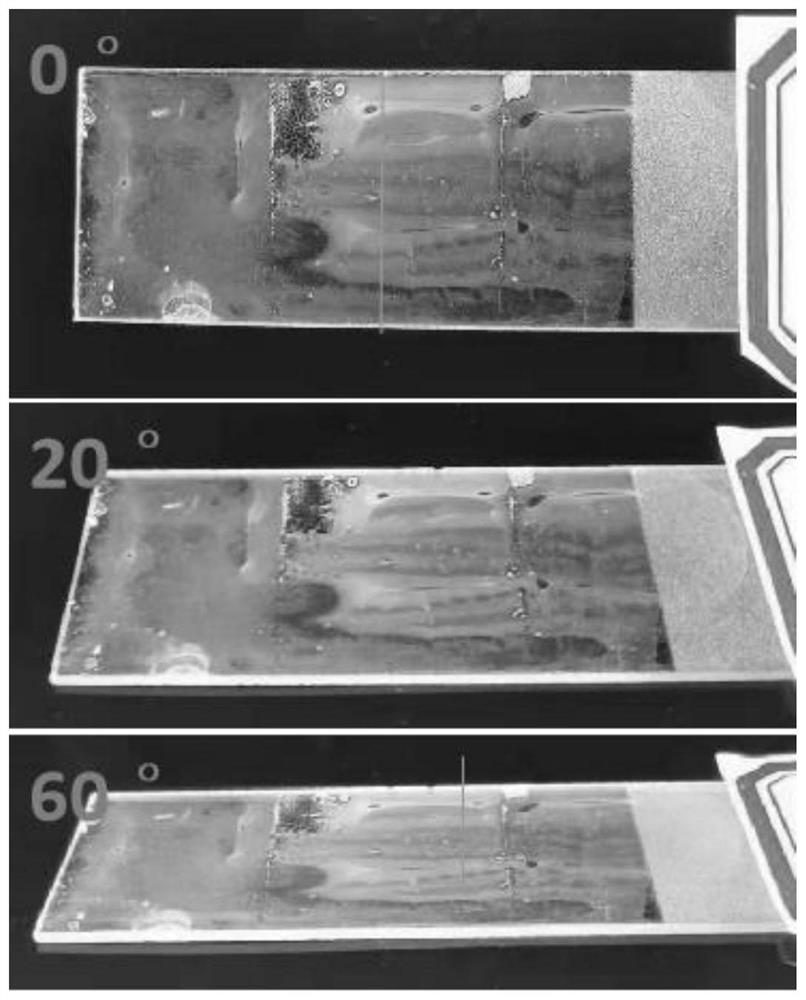

[0060] 2) Take a 4cm*16cm PET sheet, use plasma cleaning equipment to make the substrate hydrophilic, and ultrasonically clean it in ethanol solution for 3 times, and dry it with nitrogen.

[0061] 3) Take a 4cm*16cm piece of Epson photo paper, stick it on the side of a cylinder with a diameter of 5cm, and make a circle.

[0062] 4) Put the photo paper cylinder in a glass bottle with a volume of 0.5 L, add 1 ml of ethanol solution containing 5% propylsiloxane by volume, and heat in an oven at 70 degrees Celsius for 12 hours.

[0063] 5) Add 200 microliters of the colloidal particle suspension to the PET sheet, and use a 20# roller coating rod to build a thin layer of the colloidal particle suspension with a thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com