Continuous preparation method of 4-methylimidazole

A technology of methylimidazole and formamide, applied in the field of continuous preparation of 4-methylimidazole, can solve the problems of low yield and selectivity, high reaction cost, low reaction efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

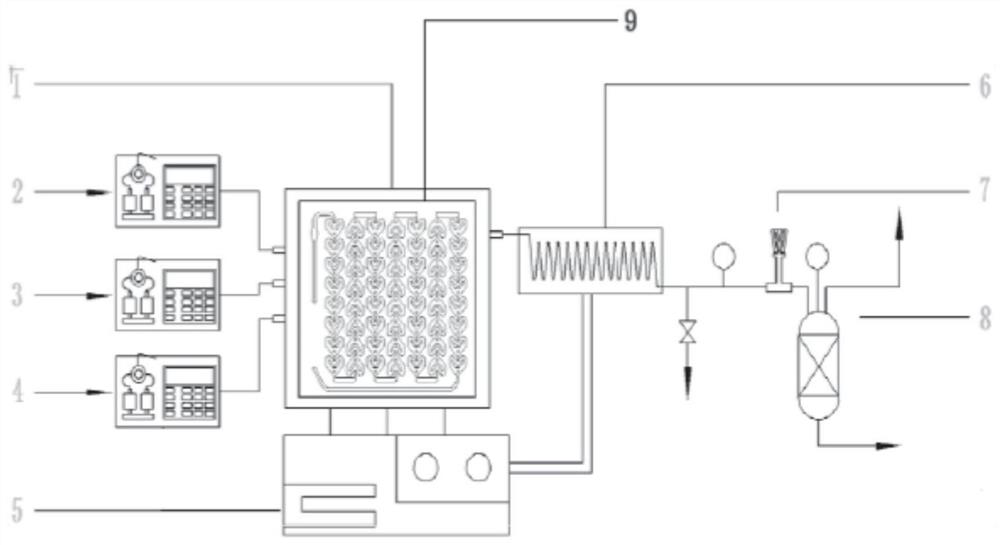

[0017] One aspect of the present invention provides a process for the continuous production of 4-methylimidazole, the process comprising the step of providing a channel reactor.

[0018] In the present invention, the channel reactor includes a microchannel reactor or a combination of a microchannel reactor and a pipe reactor. The microchannel reactor includes a fluid channel with a characteristic size of 0.5 mm to 15 mm. Tubular reactors, the channel diameter of which is 5-20 mm, microchannel reactors and pipe reactors are commercially available. The combination of microchannel reactor and pipe reactor can be freely combined after purchasing microchannel reactor and tubular reactor.

[0019] The inventors of the present invention have found that when the microchannel reactor is used in the hydroxyacetone process, the original reaction time of several hours is shortened to 3-10 minutes, thereby advantageously reducing the reaction cost and improving the product yield. An inven...

Embodiment

[0050] 1. Product analysis method

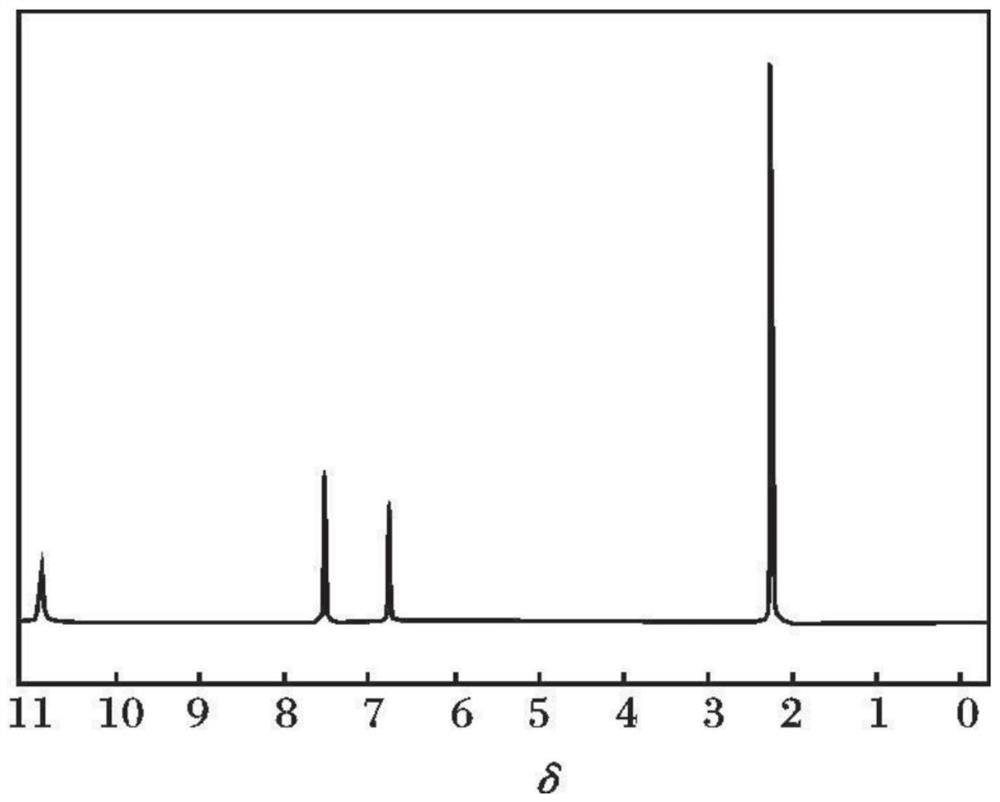

[0051] It was measured by BRUKER AVANCE 500MHz (Germany-Ruigubbrook Spectroscopy Instrument Co., Ltd.) full-digital Fourier superconducting nuclear magnetic resonance spectrometer, using standard sample sampling, and the collection result evaluation instrument was normal. Take 5 mg of solid sample, and take 0.5 ml of CDCl with a syringe 3 (Deuterated chloroform) as a solvent, inject the sample tube to fully dissolve the sample, put the sample on the rotator, measure the height of about 120mm with a gauge, put the sample into the magnet, start sampling, and output the nuclear magnetic resonance after data processing Spectrum such as figure 2 shown.

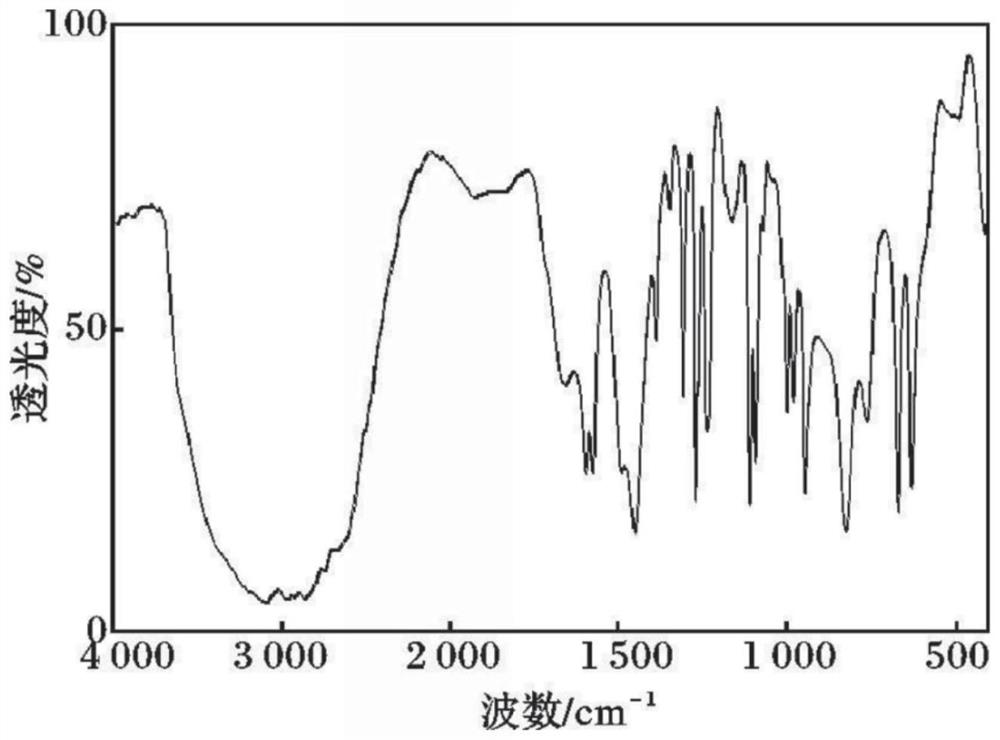

[0052] The infrared absorption was measured by IR-435 (Shimadzu, Japan) infrared spectrometer, and the potassium bromide tablet method was adopted. Take 1 mg of the product, add 100 mg of potassium bromide powder, grind it thoroughly in an agate mortar, mix it evenly, and bake it under an inf...

Embodiment 1

[0060] Liquid ammonia is pumped at a flow rate of 0.43L / min into a microchannel reactor with a liquid holding capacity of 10L purchased from Shandong Haomai Machinery Manufacturing Co., Ltd. and a channel reactor connected in series with a tubular reactor to control the pressure in the channel reactor Keeping at 4 MPa, the molar ratio of hydroxyacetone: formamide=1:4, the hydroxyacetone and formamide are pumped into the input channel for reaction with the hydroxyacetone flow rate of 0.31L / min and the formamide flow rate of 0.69L / min respectively device, the reaction temperature is 150°C, stay in the reactor for 7min, and then the reaction liquid flows into the gas-liquid separator (Beijing Century Senlang Experimental Instrument Co., Ltd., specification 1L) for gas-liquid separation, and the conversion rate of hydroxyacetone is detected The selectivity of 4-methylimidazole was 98.1%, the selectivity of 4-methylimidazole was 94.6%, and the yield of 4-methylimidazole after post-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com