Method for recovering tungsten from waste catalyst

A waste catalyst and catalyst technology, applied in the direction of improving process efficiency, etc., can solve problems such as low recovery rate, small scale, and no recovery mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

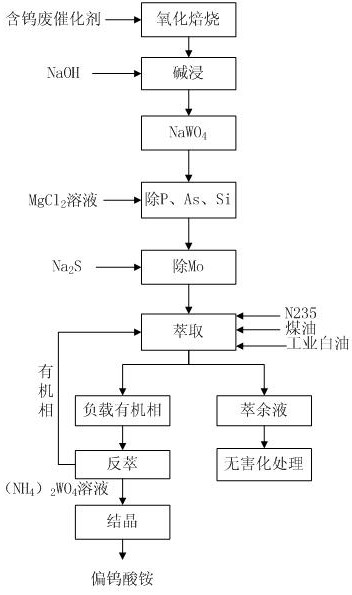

[0026] Send 500kg of waste tungsten-containing catalyst into the rotary kiln, control the roasting temperature at 650°C~750°C, oxidize and roast for 2 hours, then crush it through a ball mill, sieve it through a vibrating screen and pass it through a 100-mesh sieve. NaOH solution leaching, the pH value of the leaching solution is controlled at 9~10 to form a sodium metatungstate solution.

[0027] Add 21wt% magnesium chloride solution to the sodium metatungstate solution, adjust the pH of the liquid to 10 with 25wt% NaOH solution, and carry out precipitation and filtration to remove impurities such as P, As, and Si. Continue to add solid industrial sodium sulfide to the filtrate to make the molybdenum in the filtrate form molybdenum sulfide precipitate and remove by filtration.

[0028] The purified sodium metatungstate solution was extracted by adding 120L mixed reagent (extractant N235: diluent kerosene: No. 7 industrial white oil = 24:75:11 (volume ratio)) to obtain the loa...

Embodiment 2

[0031] Send 560kg of waste tungsten-containing catalyst into the rotary kiln, control the roasting temperature at 650°C~750°C, oxidize and roast for 2 hours, then crush it through a ball mill, sieve it through a vibrating screen and pass it through a 100-mesh sieve, and add the under-screened material to the reaction kettle with 25wt% NaOH solution leaching, the pH value of the leaching solution is controlled to 9~10 to form a sodium metatungstate solution.

[0032] Add 21wt% magnesium chloride solution to sodium metatungstate solution, adjust pH=10 with 25wt% NaOH solution, carry out precipitation and filtration to remove P, As, Si and other impurities. Continue to add solid industrial sodium sulfide to the filtrate to make the molybdenum in the filtrate form molybdenum sulfide to precipitate and remove.

[0033] The purified sodium metatungstate solution was extracted by adding 150L mixed reagent (extractant N235: diluent kerosene: No. 7 industrial white oil = 23:73:10 (volu...

Embodiment 3

[0036] Send 550kg of waste tungsten-containing catalyst into the rotary kiln, control the roasting temperature at 650°C~750°C, oxidize and roast for 2 hours, then crush it through a ball mill, sieve it through a vibrating screen and pass it through a 100-mesh sieve, and add the under-screened material to the reaction kettle with 25wt% NaOH solution leaching, the pH value of the leaching solution is controlled to 9~10 to form a sodium metatungstate solution.

[0037] Add 21wt% magnesium chloride solution to sodium metatungstate solution, adjust pH=10 with 25wt% NaOH solution, carry out precipitation and filtration to remove P, As, Si and other impurities. Continue to add solid industrial sodium sulfide to the filtrate to make the molybdenum in the filtrate form molybdenum sulfide to precipitate and remove.

[0038] The purified sodium metatungstate solution was extracted by adding 120L mixed reagent (extractant N235: diluent kerosene: No. 7 industrial white oil = 25:76:12 (volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com