Construction process of low-temperature high-flame-retardant cold storage sprayed with rigid polyurethane foam insulating layer

A technology of spraying polyurethane and construction technology, applied in the direction of heat preservation, cooling machine, refrigeration room, etc., can solve the problems of lack of heat insulation rods, aggravating the height difference of the bottom surface, and the orientation of foam molecules, so as to reduce the penetration cracking, increase the heat preservation effect, resist the The effect of increased compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

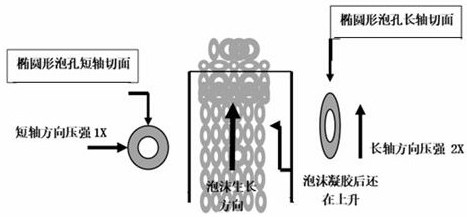

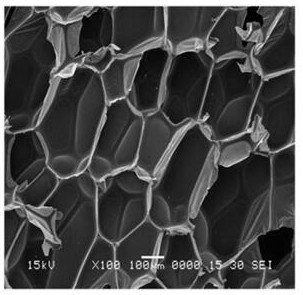

Method used

Image

Examples

Embodiment 1

[0045] The low temperature and high flame retardant spray polyurethane rigid foam insulation layer in the cold storage of this embodiment adopts a special construction process, and its specific construction steps are as follows:

[0046] 1) On the civil wall of the cold storage, a layer of galvanized iron plate with a thickness of 0.3mm is bonded as a whole.

[0047] 2) Install on the galvanized iron plate at intervals with a length of 200mm and a cross-sectional area of 4cm 2 The wooden pillars are vertical to the wall, the vertical and horizontal spacing of the pillars is 200mm, and they are evenly distributed on the wall in a matrix. Both ends of the pillars are fixed with NdFeB magnets, and one end of the pillars is magnetically attracted to the galvanized iron plate. superior;

[0048] 3) Place and install a color steel plate with a width of 1000mm on the other end of the wooden pillar, and the color steel plate is fixed by NdFeB magnets;

[0049] 4) The spraying dens...

Embodiment 2

[0056] This embodiment adopts the conventional cold storage construction process of spraying B1 grade polyurethane insulation material, and its specific construction steps are as follows:

[0057] 1) Install T-shaped wooden keels with a height of 200mm on the wall. The wooden keels are installed horizontally, parallel to each other, and the distance between them is 1000mm.

[0058] 2) The spraying density on the cold storage wall is about 50kg / m 3 The flame retardant is B1 grade polyurethane foam, the spraying direction of the spray gun is perpendicular to the wall, the expansion and growth direction of the foam is perpendicular to the wall, and it is sprayed layer by layer many times.

[0059] 3) Install the anti-crack steel wire mesh when the thickness of the sprayed polyurethane foam reaches about 100mm.

[0060] 4) Continue to spray layer by layer so that the thickness of the foam reaches the thickness of the wooden keel (200mm)

[0061] 5) Use rivets to install the oute...

Embodiment 3

[0068] This embodiment adopts the conventional cold storage construction process of spraying B1 grade polyurethane thermal insulation material, and its specific construction steps are as follows:

[0069] 1) Install T-shaped wooden keels with a height of 200mm on the wall. The wooden keels are installed horizontally, parallel to each other, and the distance between them is 1000mm.

[0070] 2) The spraying density on the cold storage wall is about 50kg / m 3 The flame retardant is B1 grade polyurethane foam, the spraying direction of the spray gun is perpendicular to the wall, the expansion and growth direction of the foam is perpendicular to the wall, and it is sprayed layer by layer many times.

[0071] 3) Continue to spray layer by layer so that the thickness of the foam reaches the thickness of the wooden keel (200mm)

[0072] 4) Use rivets to install the outer protective surface of the color steel plate on the wooden keel, and complete the construction of the foam layer of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com