Optical waveguide type light combiner and projection device using same

An optical waveguide and waveguide technology, applied in the field of optical projection display, can solve the problems of weak confinement, large optical path size, low refractive index, etc., and achieve the effect of strong confinement ability, small bending radius and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

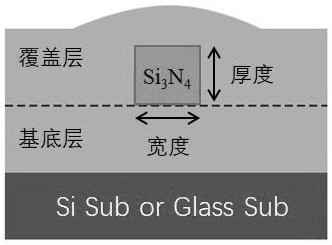

[0055] Schematic diagram of the optical waveguide section figure 1 As shown, there is a layer of SiO on a silicon wafer or glass substrate 2 The base layer has a thickness of 2 μm; the core layer of the optical waveguide is Si 3 N 4 , its thickness and width are both 0.16 μm; there is SiO on top 2 As a covering layer to ensure the reliability of the waveguide. The cladding layer (including the base layer and the cladding layer, which are made of the same material in this embodiment) and the refractive index of the core layer of the optical waveguide are shown in Table 1.

[0056] Table 1 Cladding and core refractive index of optical waveguide

[0057]

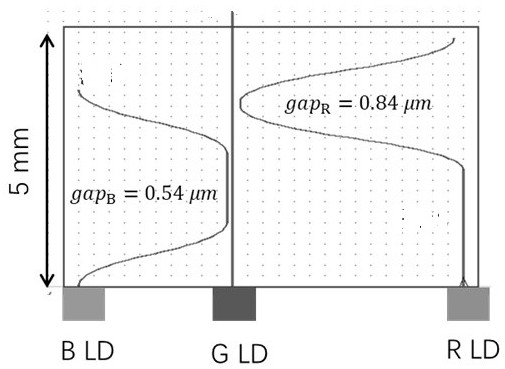

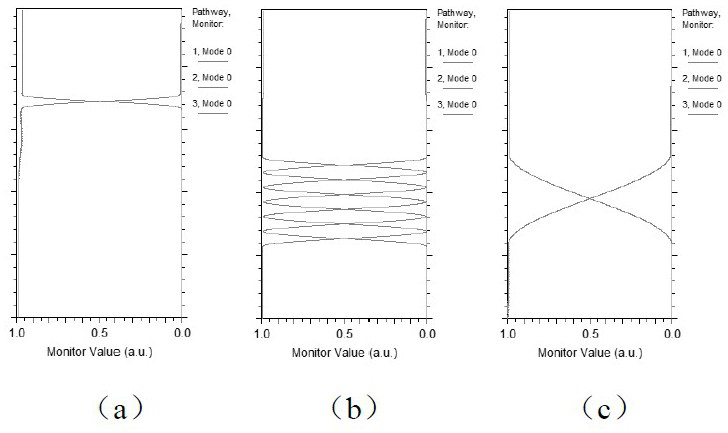

[0058] refer to figure 2 As shown, the red, green, and blue monochromatic laser beams respectively enter the three optical waveguides through the coupler, and the blue light wavelength is 450 nm, which is generated by a GaN-based semiconductor laser and enters the leftmost optical waveguide (this embodiment The middle...

Embodiment 2

[0062] Schematic diagram of the optical waveguide section figure 1 As shown, there is a layer of SiO on a silicon wafer or glass substrate 2 The base layer has a thickness of 2 μm; the core layer of the optical waveguide is Si 3 N 4 , its thickness and width are both 0.16 μm; there is SiO on top 2 As a covering layer to ensure the reliability of the waveguide.

[0063] refer to Figure 4 As shown, the red, green, and blue monochromatic laser beams respectively enter the three optical waveguides through the coupler. The blue light has a wavelength of 450 nm, which is generated by a GaN-based semiconductor laser and enters the middle optical waveguide (in this embodiment, the lower The wavelength of green light is 520nm, which is generated by InAlGaN-based semiconductor laser, and enters the left optical waveguide (hereinafter referred to as optical waveguide 1 in this embodiment); the wavelength of red light is 638nm, which is produced by AlGaInP The base semiconductor las...

Embodiment 3

[0067] In order to increase the output power of red light, two red lasers, one green laser and one blue laser can be combined for light.

[0068] Schematic diagram of the optical waveguide section figure 1 As shown, there is a layer of SiO on a silicon wafer or glass substrate 2 The base layer has a thickness of 2 μm; the core layer of the optical waveguide is Si 3 N 4 , its thickness and width are both 0.16 μm; there is SiO on top 2 As a covering layer to ensure the reliability of the waveguide.

[0069] refer to Figure 5 As shown, the blue laser with a wavelength of 450 nm is coupled into the optical waveguide for propagating blue laser (left 1, referred to as optical waveguide 1 in this embodiment); the green laser with a wavelength of 520 nm is coupled into the optical waveguide for propagating green laser (left 2, referred to as optical waveguide 2 in this embodiment); red laser light with a wavelength of 638nm is coupled into the first optical waveguide for propaga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com