Protein/polysaccharide composite membrane material with tea polyphenol cross-linked and embedded nano cerium oxide and preparation method of protein/polysaccharide composite membrane material

A composite technology of nano-cerium oxide and polysaccharide, applied in the field of nano-materials, can solve the problems of high equipment requirements and high cost, and achieve the effects of good mechanical properties, solving cytotoxicity and excellent ultraviolet protection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

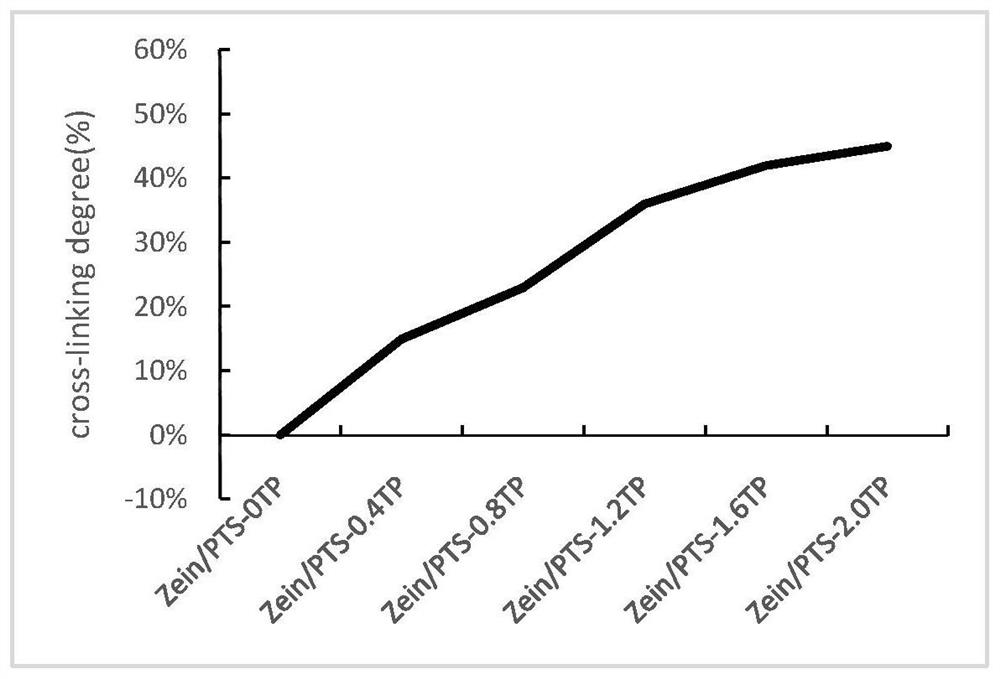

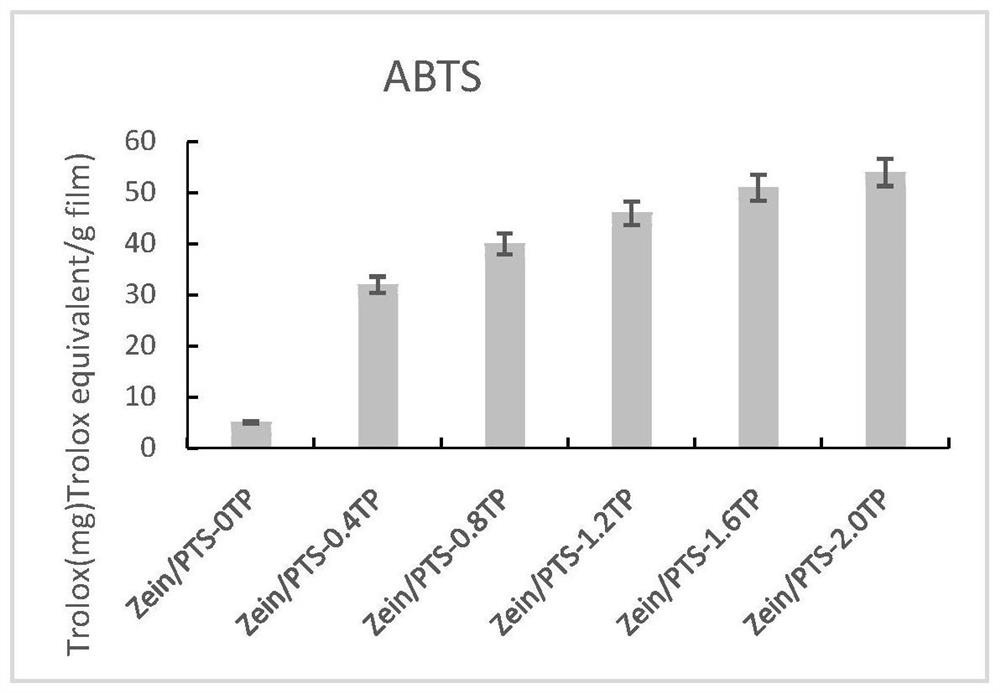

[0030] (1) Dissolve 500 mg of zein in 50 ml of 75% ethanol solution at 60°C, heat and reflux and stir for 20 minutes, weigh 100 mg of fucoidan into the solution, continue heating and reflux and stir for 20 minutes to obtain blend A;

[0031] (2) Add 100 mg of cerium nitrate hexahydrate, 120 mg of urea, and 1.8 g of PVP to the blend A in sequence to adjust the pH to 8-9, and heat and reflux to stir;

[0032] (3) Add 0.4% tea polyphenols (w / w, zein / TP), 100 μL glycerol and 100 μL Tween to the reaction solution, and continue heating and stirring for 30 minutes;

[0033] (4) Filtrate the obtained mixed solution under reduced pressure to obtain a film-forming solution, spread it evenly on an acrylic plate, and dry it in vacuum at 60°C for 18 hours to obtain a protein / polysaccharide composite film with tea polyphenols cross-linked and embedded in nano-cerium oxide Material-1.

Embodiment 2

[0035] (1) Dissolve 500 mg of zein in 50 ml of 75% ethanol solution at 60°C, heat and reflux and stir for 20 minutes, weigh 100 mg of fucoidan into the solution, continue heating and reflux and stir for 20 minutes to obtain blend A;

[0036] (2) Add 100 mg of cerium nitrate hexahydrate, 120 mg of urea, and 1.8 g of PVP to the blend A in sequence to adjust the pH to 8-9, and heat and reflux to stir;

[0037] (3) Add 0.8% tea polyphenols (w / w, zein / TP), 100 μL glycerol and 100 μL Tween to the reaction solution, and continue heating and stirring for 30 minutes;

[0038] (4) Filtrate the obtained mixed solution under reduced pressure to obtain a film-forming solution, spread it evenly on an acrylic plate, and dry it in vacuum at 60°C for 18 hours to obtain a protein / polysaccharide composite film with tea polyphenols cross-linked and embedded in nano-cerium oxide Material-2.

Embodiment 3

[0040] (1) Dissolve 500 mg of zein in 50 ml of 75% ethanol solution at 60°C, heat and reflux and stir for 20 minutes, weigh 100 mg of fucoidan into the solution, continue heating and reflux and stir for 20 minutes to obtain blend A;

[0041] (2) Add 100 mg of cerium nitrate hexahydrate, 120 mg of urea, and 1.8 g of PVP to the blend A in sequence to adjust the pH to 8-9, and heat and reflux to stir;

[0042] (3) Add 1.2% tea polyphenols (W / W, zein / TP), 100 μL glycerol and 100 μL Tween to the reaction solution, and continue heating and stirring for 30 minutes;

[0043] (4) Filtrate the obtained mixed solution under reduced pressure to obtain a film-forming solution, spread it evenly on an acrylic plate, and dry it in vacuum at 60°C for 18 hours to obtain a protein / polysaccharide composite film with tea polyphenols cross-linked and embedded in nano-cerium oxide Material-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com