Method for synthesizing hexanoic acid from high-yield sludge open system

A high-yield, sludge technology, applied in the field of environmental engineering, can solve the problems of low caproic acid production, such as the tolerance of Clostridium krujiri, to strengthen the advantages of caproic acid-producing bacteria, reduce substrate competition, and increase caproic acid production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Anaerobic sludge alkali heat treatment: the anaerobic sludge taken from the river bottom is diluted with water, and the total solid content after dilution is 4.5% to 5%, and the pH of the sludge is adjusted to 12 and maintained for 6 hours. After alkali treatment, adjust its pH to 7.0, heat and boil for 30 minutes, then cool to room temperature.

[0035] Wheat straw pretreatment: the wheat straw taken from the farmland is crushed with a pulverizer to a particle size of 0.5-1.0 cm.

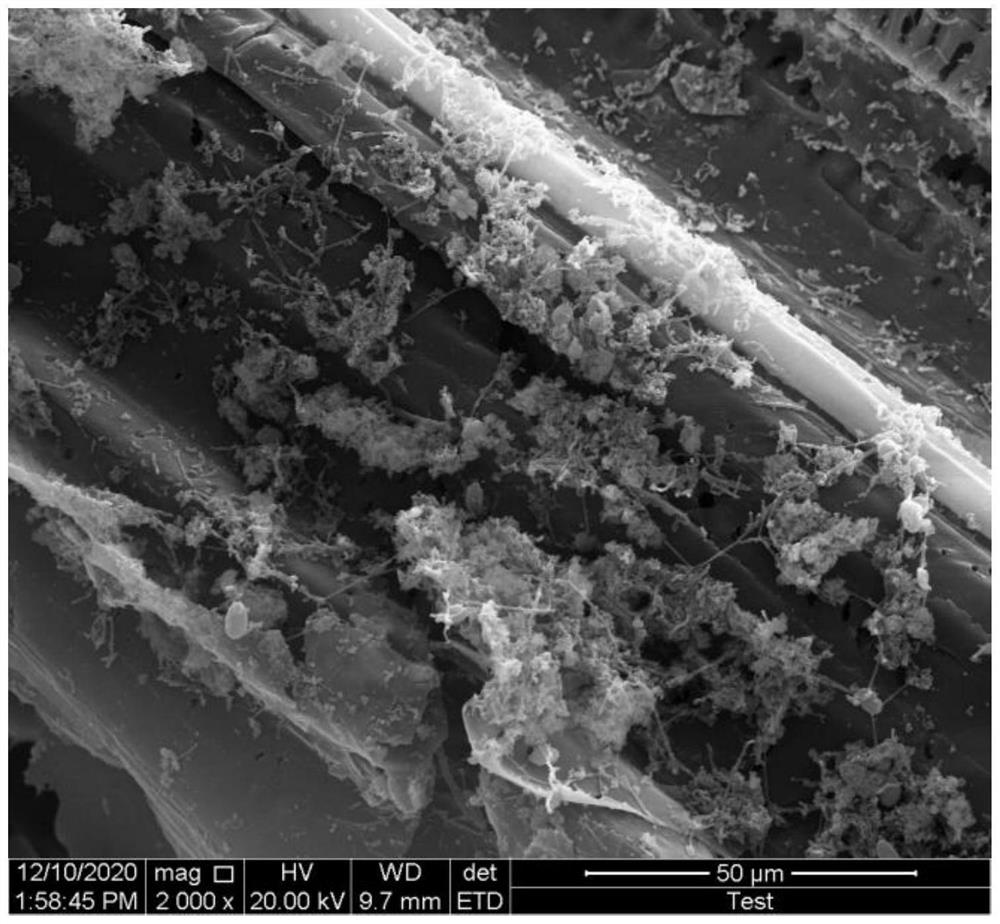

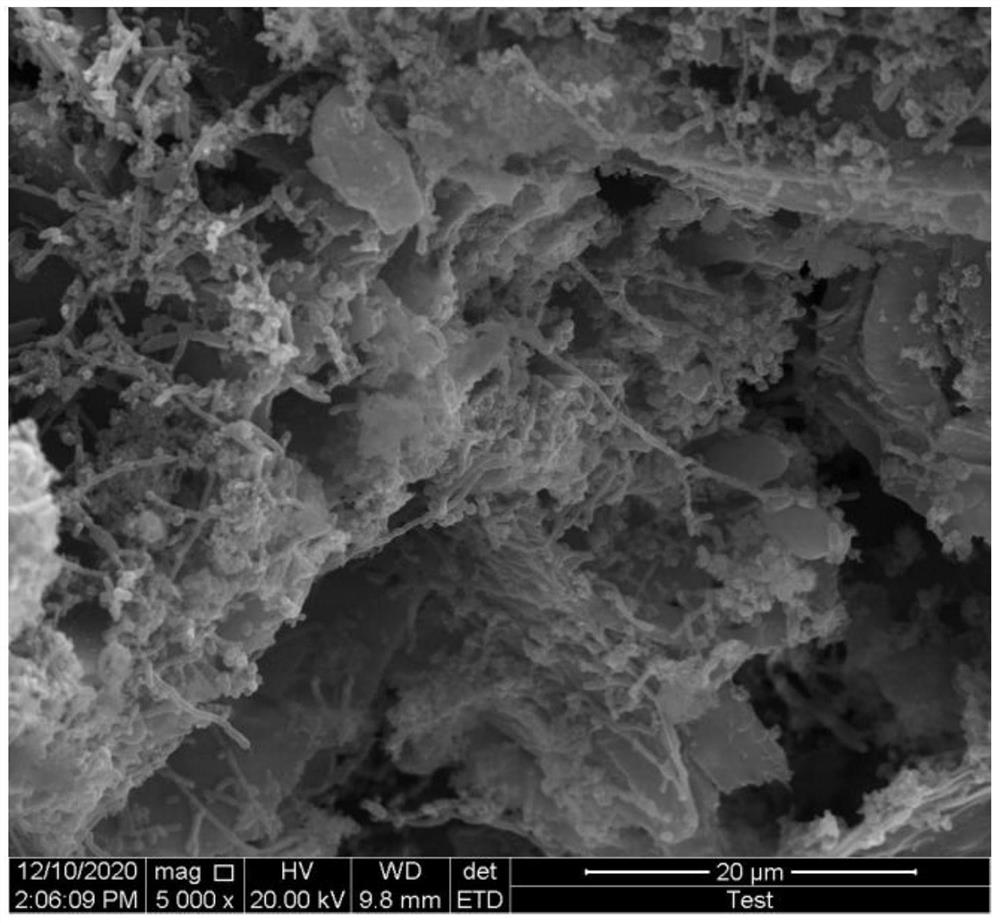

[0036] Cultivation of Clostridium krujiri biofilm: add 20g of wheat straw to an anaerobic bottle with a volume of 1L, take 0.5L of the culture medium and add it to the anaerobic bottle. 2 Boil for 1 min under the conditions and cool to room temperature, quickly add 8 g of absolute ethanol, and quickly seal the anaerobic bottle with a butyl stopper. After sterilization, add 1.25g NaHCO 3 sterile NaHCO 3 solution and Na containing 40 mg sodium sulfide 2 S solution. After being inoculated wi...

Embodiment 2

[0040] Anaerobic sludge alkali heat treatment: the anaerobic sludge taken from the river bottom is diluted with water, and the total solid content after dilution is 4.5% to 5%, and the pH of the sludge is adjusted to 12 and maintained for 6 hours. After alkali treatment, adjust its pH to 7.0, heat and boil for 30 minutes, then cool to room temperature.

[0041] Wheat straw pretreatment: the wheat straw taken from the farmland is crushed with a pulverizer to a particle size of 0.5-1.0 cm.

[0042] Cultivation of Clostridium krujiri biofilm: add 20g of wheat straw to an anaerobic bottle with a volume of 1L, take 0.5L of the culture medium and add it to the anaerobic bottle. 2 Boil for 1 min under the conditions and cool to room temperature, quickly add 8 g of absolute ethanol, and quickly seal the anaerobic bottle with a butyl stopper. After sterilization, add 1.25g NaHCO 3 sterile NaHCO 3 solution and Na containing 40 mg sodium sulfide 2 S solution. After being inoculated ...

Embodiment 3

[0046] Anaerobic sludge alkali heat treatment: the anaerobic sludge taken from the river bottom is diluted with water, and the total solid content after dilution is 4.5% to 5%, and the pH of the sludge is adjusted to 12 and maintained for 6 hours. After alkali treatment, adjust its pH to 7.0, heat and boil for 30 minutes, then cool to room temperature.

[0047] Wheat straw pretreatment: the wheat straw taken from the farmland is crushed with a pulverizer to a particle size of 0.5-1.0 cm.

[0048] Cultivation of Clostridium krujiri biofilm: add 20g of wheat straw to an anaerobic bottle with a volume of 1L, take 0.5L of the culture medium and add it to the anaerobic bottle. 2 Boil for 1 min under the conditions and cool to room temperature, quickly add 8 g of absolute ethanol, and quickly seal the anaerobic bottle with a butyl stopper. After sterilization, sequentially add 1.25g NaHCO 3 into sterile NaHCO 3 solution and Na containing 40 mg sodium sulfide 2 S solution. After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com