Directional growth method of bismuth telluride thermoelectric material

A thermoelectric material, directional growth technology, applied in polycrystalline material growth, chemical instruments and methods, single crystal growth, etc., can solve problems such as difficult and low-cost large-scale production, thermoelectric performance limitations, and inability to obtain crystals, etc., to achieve inhibition Oblique crystallization, improvement of oblique cracks or local defects at corners, and inhibition of radial heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

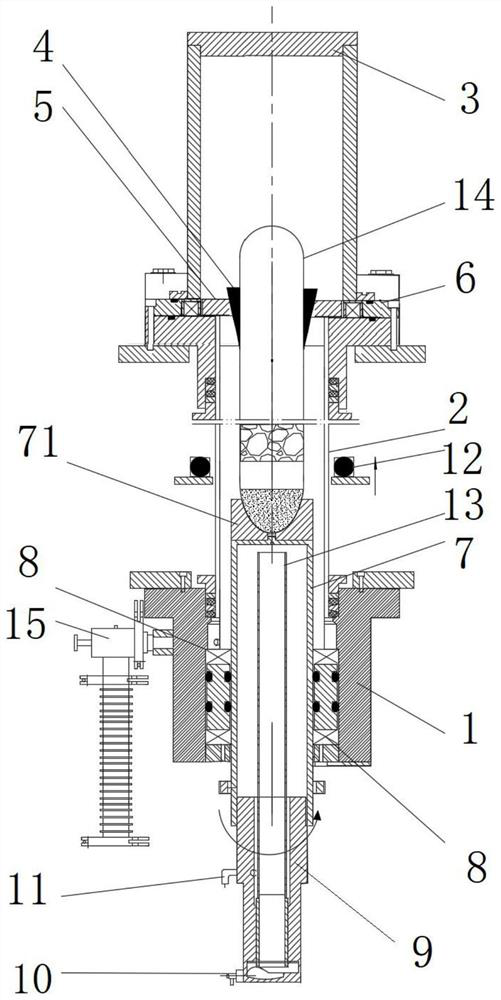

[0056] see figure 1 , specific embodiment 1: a kind of directional growth method of bismuth telluride thermoelectric material, comprising the steps:

[0057] Step 1, prepare the bismuth telluride thermoelectric material to be melted in the zone, seal the bismuth telluride thermoelectric material in the heat-resistant pipe fitting 14, the bismuth telluride thermoelectric material is in a vacuum or an inert gas under a certain pressure, and the heat-resistant pipe fitting 14 is made of quartz. Tube or Pyrex tube;

[0058] In step 2, the heat-resistant pipe fitting 14 containing the bismuth telluride thermoelectric material is put into the vacuum chamber. At the top, there is a water cooling channel for conveying water coolant inside the rotating support shaft;

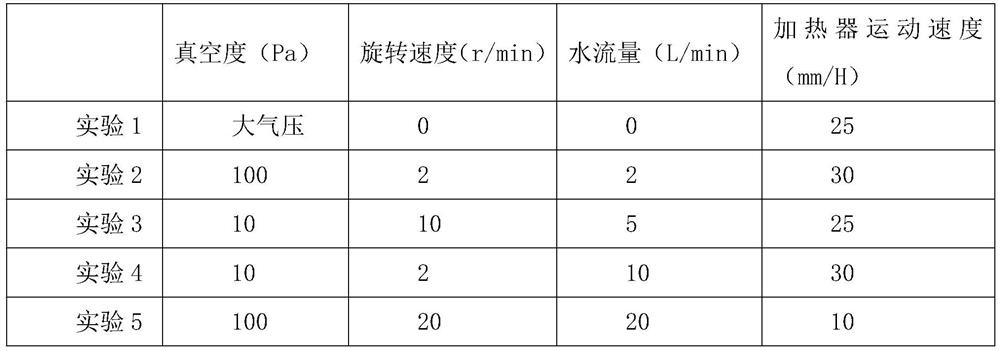

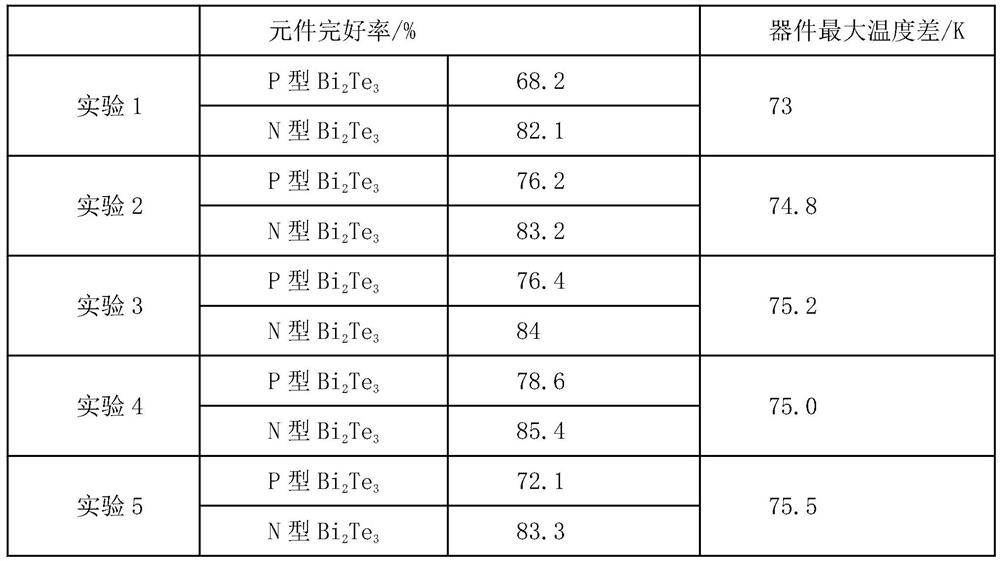

[0059] Step 3: Prepare Bi by zone melting method 2 Te 3 Crystal; the vacuum degree of the quartz tube 2 cavity is not more than 100Pa; the rotation speed of the rotating support shaft is 2rpm-20rpm; the zone melting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com