Preparation method and application of composite material for capturing carbon dioxide

A composite material and carbon dioxide technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of few hydrophobic carbon dioxide capture materials and affect carbon dioxide adsorption performance, and achieve simple preparation methods and reduce water vapor The effect of good hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

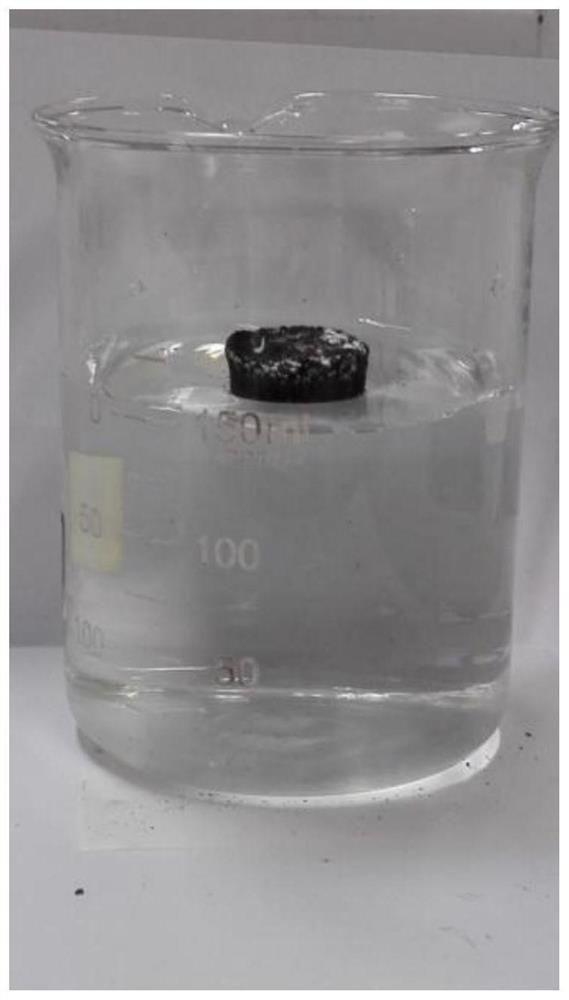

[0036] see Figure 1~4 , the present invention provides a method for preparing a composite material for carbon dioxide capture, the preparation method is simple, the prepared composite material is porous, and has good hydrophobic properties, and can be used for capturing carbon dioxide in a water vapor environment , reduce the influence of water vapor in the process of capturing carbon dioxide in the flue gas, effectively solve the problem in the prior art that when the flue gas is captured, the water vapor in the flue gas occupies the adsorption site of the carbon dioxide capture material, resulting in a decrease in the adsorption performance of carbon dioxide .

[0037] The invention provides a method for preparing a composite material for carbon dioxide capture, the method for preparing the composite material comprises the following steps:

[0038] S1. Dissolving polyaldehydes and nitrogen-containing heterocyclic compounds in glacial acetic acid to prepare a mixed solution...

Embodiment 1

[0068] This embodiment provides a method for preparing a composite material for carbon dioxide capture, the method for preparing the composite material includes the following steps:

[0069] S1, terephthalaldehyde and pyrrole are dissolved in glacial acetic acid, are mixed with the ethyl acetate mixed solution containing the terephthalaldehyde of 0.1mol / L and the pyrrole containing 0.1mol / L;

[0070] S2. Stir the ethyl acetate mixed solution under nitrogen for 0.5 h, then add ferric chloride and continue stirring for 4 h to obtain an organic polymer precursor solution, which is placed in a hydrothermal reaction kettle, and heated at 180° C. for 72 h, Obtain organic polymer reaction solution; Wherein, the ratio between iron trichloride (mol) and glacial acetic acid (L) is 0.05mol / L;

[0071] S3. After cooling the organic polymer reaction liquid naturally, washing it with deionized water, methanol, acetone, tetrahydrofuran and chloroform in sequence, and placing it in a vacuum d...

Embodiment 2

[0076] This embodiment provides a method for preparing a composite material for carbon dioxide capture. The difference between the preparation method of this composite material and Example 1 is that in step S1, it is formulated to contain 0.2 mol / L terephthalaldehyde and 0.2 mol / L / L pyrrole ethyl acetate mixed solution; the protective gas in step S2 is argon; other methods and steps are the same as those in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com